Photo by Chris Arend Photography

Photo by Chris Arend Photography

ike is our visionary,” says Heath Martin, co-owner of KLEBS Mechanical, Alaska’s largest full-service residential and commercial plumbing, sheet metal, and mechanical services contractor.

In 2018, Mike Klebs joined forces with Martin to buy KLEBS Mechanical from his father, Gary Klebs, who started the company in 1986 as a commercial sheet-metal contractor. Since then, it has been Mike Klebs’ vision that has kept KLEBS Mechanical steady through the Alaska economy’s ups and downs.

As the commercial side of KLEBS grew, Mike Klebs recalls, existing clients were starting to request KLEBS Mechanical’s services installing home furnaces and boilers. In 1993, KLEBS launched a residential department.

“We’ve always been heavy commercial, and adding the residential component didn’t change that,” Mike Klebs says.

Photo courtesy of KLEBS Mechanical

“We did that mainly because the clients wanted us to,” Mike Klebs says. “They saw the quality and the pricing on our HVAC projects, and they wanted us to take charge of the whole mechanical scope.”

Meanwhile, the Alaska economy was booming; growth in the economy inspired growth at KLEBS Mechanical, as the company’s commercial construction division took on larger projects.

KLEBS Mechanical’s commercial division regularly tackled projects like retail stores—Fred Meyer, Home Depot, and Target—and restaurants, in addition to remote work. “But we started getting opportunities to do larger work, like office buildings and airport work. We did a four-story office building for Chugach Alaska Corporation on 36th Avenue [now owned by Tatitlek Corporation], which was a large project for us at the time, as well as the Anchorage Rental Car Center and parking garage project at the Ted Stevens Anchorage International Airport.”

Photo courtesy of KLEBS Mechanical

“We’ve done very large camps on the North Slope that KLEBS has been key in installing and moving,” says Marvin Olson, project manager for ICE Services, Inc. “Their work has to be highly skilled in order to make timelines, and I always rely on them for that. Their costing is fair, they’re always on budget, and on time.”

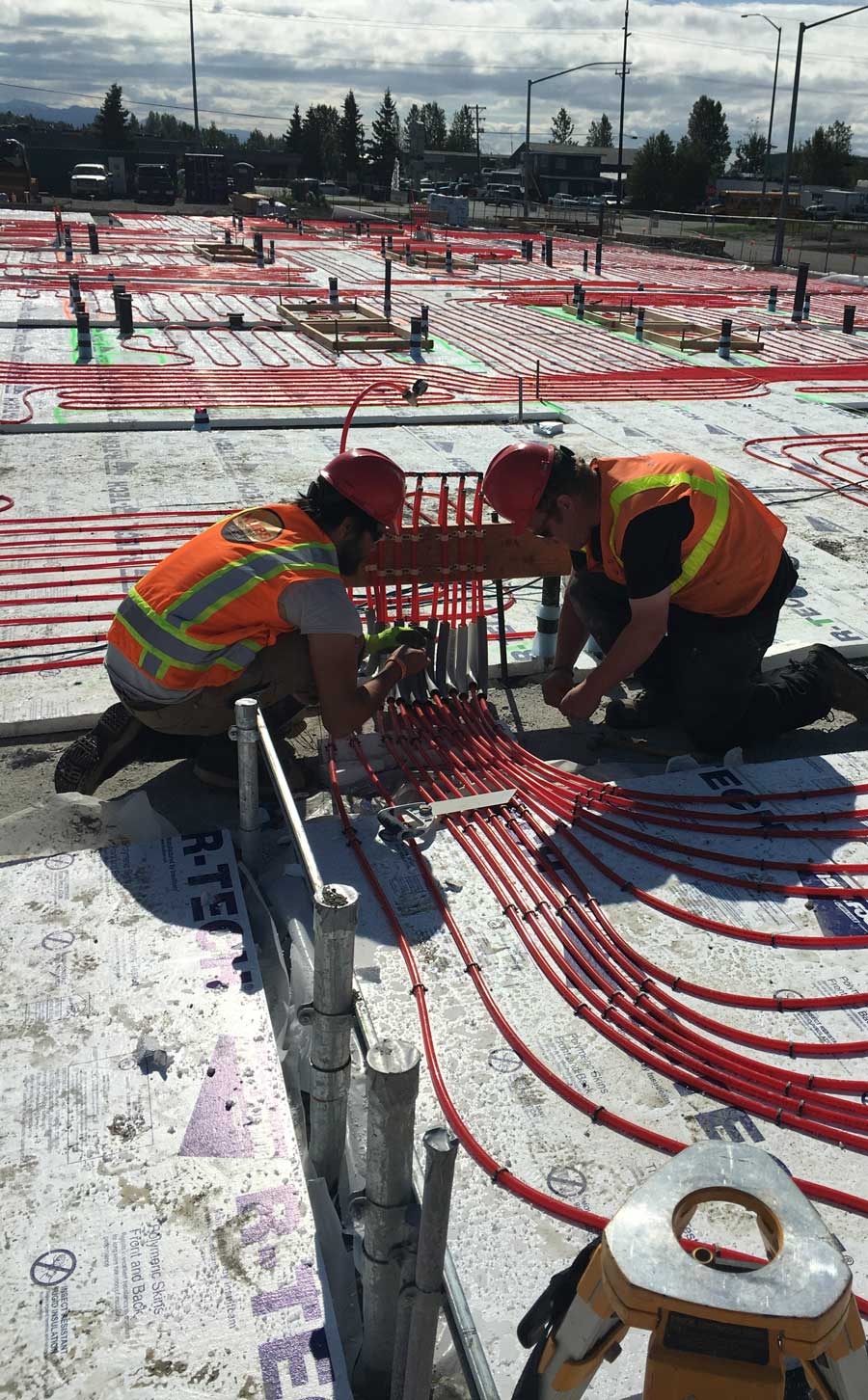

Prefabrication and preassembly are key parts of that cost savings, especially when it comes to remote work: The KLEBS team pre-builds pieces of mechanical systems in their shop in a controlled environment and then ships those pieces to the job site to be put in place.

Photo courtesy of KLEBS Mechanical

“We try to be as innovative as possible,” Mike Klebs says.

He credits AGC with helping companies like KLEBS Mechanical make connections with clients and fellow AGC members that allow for information sharing. “The wealth of knowledge that’s passed along, even during COVID-19, through webinars, trainings, and networking, is just invaluable.”