ince Doug and Priscilla Graham started their family-owned and operated industrial coatings company in 1997, it’s been the sort of place where the office is full of family, children, and dogs. The couple raised their three daughters in Fairbanks while operating their business, relocating the business and their family to Palmer in 2009.

These days, Priscilla is CEO and 80 percent owner and functions on a day-to-day basis as the controller of the fifteen- to thirty-person company. Doug is the COO, and daughter Noelle handles contract administration, with daughter Megan handling accounts receivable, accounts payable, and payroll. Noelle is now mom to baby Emmett, who joins her at work most days as the third generation of this family business.

Both daughters are well-educated and had numerous other professional options but chose to work alongside their dad, Doug says.

“We are fortunate to actually have our kids be a part of the business,” Priscilla says. “They put their heart and soul into it, as well, and watch over it as if it was their own.”

In fact, he sold the business in 2011; it was an opportunity to consider a career change.

“My midlife crisis involved a Cessna 185, not a Corvette,” Doug says. “I basically went flying for three years and had some time to think.”

He says he realized that life was more about who you are, not what you do. He knew the industrial coatings and corrosion control industry well and decided to return to his known craft rather than start a new career.

In December 2013, an opportunity arose to re-purchase their company assets, and that’s when the family changed the name to Graham Industrial Coatings, LLC, or GIC.

“Every person matters. They have a story. They have needs. We try to be human in the process of solving these difficult infrastructure problems,” he says.

After twenty-six years of tenacious commitment to clients’ needs, GIC has earned a reputation for delivering innovative solutions across Alaska and beyond. About 90 percent of the company’s work comes from referrals and repeat customers.

GIC’s services include commercial painting and industrial sandblasting, coatings and linings, polyurethane foam, and metalizing.

The company specializes in restoring or preserving useful life to infrastructure, such as tank farms, pipelines, bridges, water and wastewater plants, and national defense infrastructure through corrosion-prevention and fireproofing.

The Allison Creek Hydroelectric Project in Valdez is an example of creative problem-solving that has earned the company a reputation in the industry for engineering innovative and cost-effective solutions, Doug says.

“They came to us with a problem,” Doug says.

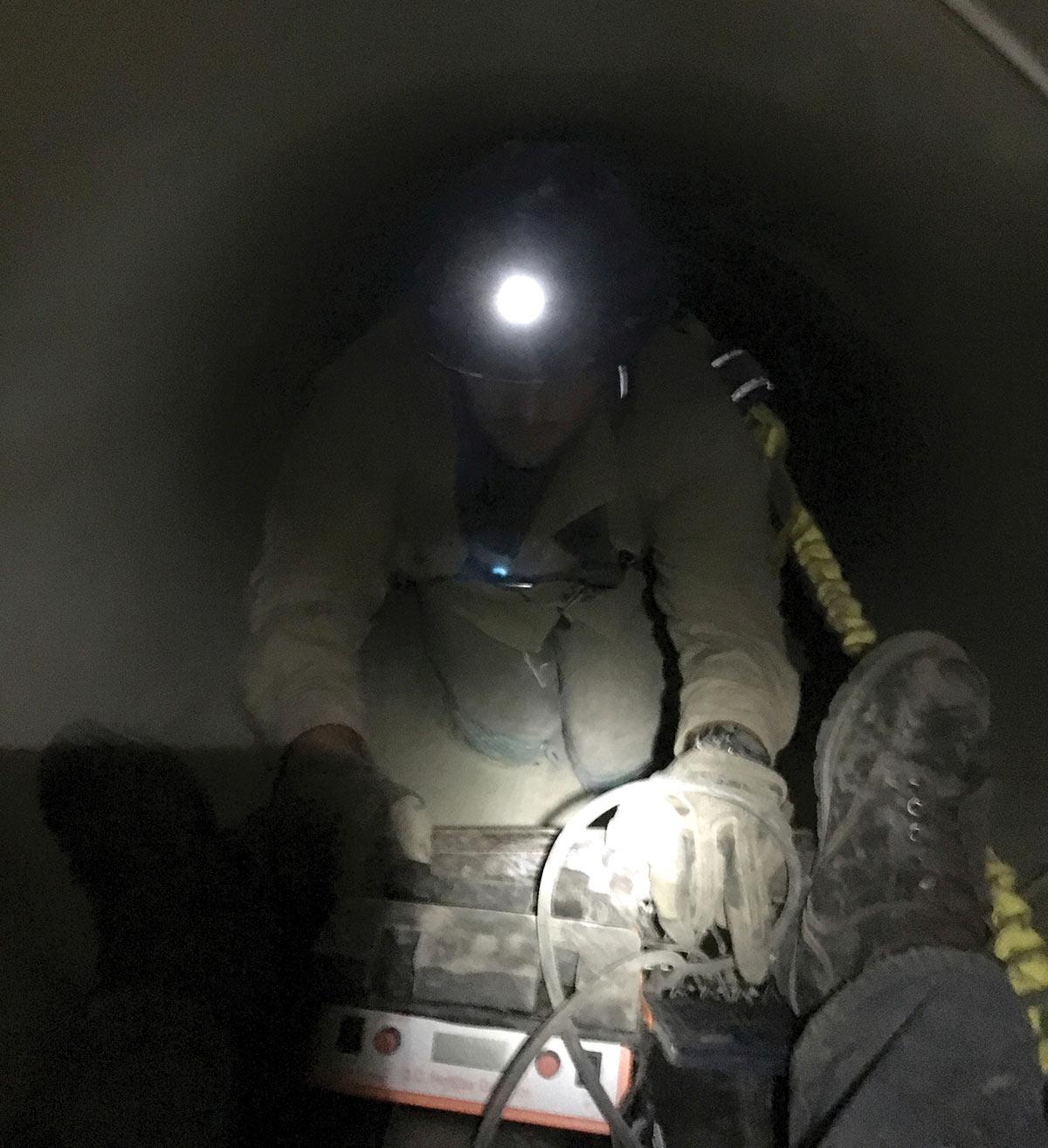

The problem was putting workers and equipment in an underground pipeline with an average angle of 30 degrees, with some sections reaching angles of nearly 50 degrees.

“Imagine trying to climb up the steepest slide at your nearest McDonald’s Play Place,” Doug says. “We needed to work up and down the length of the pipeline safely and productively.”

Careful research led Doug into the world of elevator winches and underground mining.

“I bought a retrieval winch certified for human conveyance,” Doug says.

GIC built a prototype semi-circular work crawler that comfortably held a worker and various tools needed for the job and featured bucket holders on gimbals.

“We finished the project ahead of time, and under budget,” Doug says.

The client was more than pleased.

“Doug, you and your team have performed exceptionally. The Graham Industrial crew has worked hard and done so safely. Your quality is exceptional. We cannot ask for more. McMillen is thoroughly satisfied with your performance on Allison Creek,” Travis Shelton, formerly a project manager at Boise, Idaho-based McMillen LLC, stated in a testimonial written for Graham Industrial.

A few months after the close of the project, McMillen reached out to GIC and made a generous offer to buy the retrieval system.

“Our guys still talk about Allison Creek as one of their favorite projects,” Doug says.

“AGC of Alaska is an essential resource for our business. The organization is much more than a Plans Room,” Doug says.

In addition to access to the well-managed plans room, GIC uses AGC’s training resources and the contractor network. Flipping through the Spring 2023 edition of The Alaska Contractor on the corner of his desk, he says the magazine is another way the trade association serves its members.

“This magazine always inspires us to be better,” Doug says.