echnology has come a long way since 1995. “Work that was previously done in the office is now done in the field,” says Matt Crow, owner of Alaska Construction Surveys, or ACS. “Technology has made it possible to reduce our workforce as well as increase productivity.”

Today, ACS relies on GPS, robotics, 3D scanning, aerial drones, and other technology to collect data in complicated environments for design and construction projects throughout Alaska.

But no technology can replace experience: ACS crews constantly train to stay current with new techniques, equipment, and software, and it’s their expertise that makes ACS Southcentral Alaska’s go-to survey company.

“Technology can provide very precise data, but it’s the knowledge of the trained surveyor to determine if it’s accurate,” Crow says. “And although technology has made work faster, companies are now faced with a high volume of data that requires office staff that is skilled in data management.”

In ’95, Crow began working for Michael Kahler and Tim Felegy, who had just started ACS out of a garage. Crow joined the company straight out of UAA’s geomatics program. He bought the company out in 2016.

ACS started out concentrating on heavy civil construction surveying, which remains the “bread and butter of ACS surveying in southcentral Alaska.”

“I enjoy that we’re there through the entirety of a project,” Crow says. “We go in before any construction starts, locate monumentation, and collect data to track quantities. We lay out the utilities, roadway grades, curbs, bridges, and buildings. We’re with the project all the way up to the final pavement, and then lay out final striping for the road. It’s neat to see the entire project through from beginning to end.”

On a recent project to install left-turn lanes on Seward Highway between Miles 100 and 105, ACS is completing all survey work—and in keeping with their reputation, going above and beyond for their client, the Alaska Department of Transportation & Public Facilities, or DOT&PF.

For a floating vertical control section of the highway, ACS designed a profile that DOT&PF could build to. “It was really a design-build on a good portion of the project, which is unique,” says DOT&PF Senior Project Engineer James Lambardo.

“ACS has always been really good about doing additional work in a timely fashion,” Lambardo says. “To date, I’ve never had them say, ‘We can’t do that,’ on anything I’ve asked them to do.”

While road construction provides the bulk of ACS’s projects, the surveyor’s close relationships with utilities like Chugach Electric Association have produced some of their best work.

Three years ago, Chugach needed to update and repair its Point MacKenzie substation, which had suffered damage from the November 2018 earthquake. But because the facility was originally built over a period of ten years in the ’70s and ’80s, Chugach didn’t have much design data to inform the as-built survey they’d requested from ACS.

ACS used 3D scanners throughout the facility to collect millions of data points by sending out a beam that reflects off surfaces. They used that data to create a 3D model of the substation’s interior.

“It’s like making a collage that brings all the points together, and you can literally view the facility as if you’re standing inside of it,” Crow describes.

It would have been nearly impossible to physically survey the substation, he says, because of the enormous amount of wires, cabling, and structures. With the 3D scanner, ACS was able to accurately measure every inch of the complicated site.

“That space was challenging, and having that technology allowed ACS to produce something we hadn’t had before,” says Shawn Wendling, senior projects manager at Chugach. “That’s the value-add ACS brings to a project. For every dollar you pay them, you get a return of $1.50 because they’re constantly bringing you more than you asked for.”

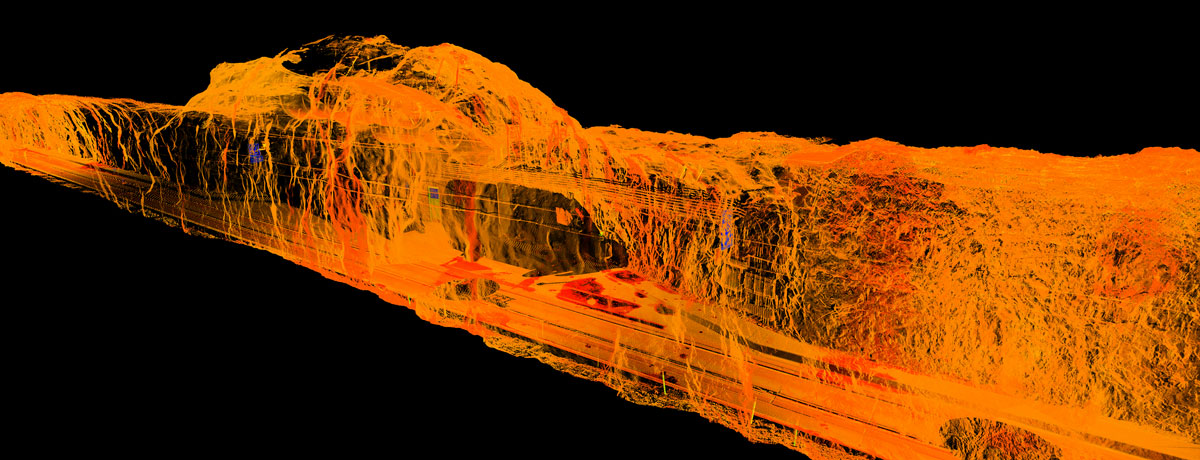

Crow knew 3D scanning would be ideal for the Point MacKenzie substation project because ACS had used it before to scan the Whittier Tunnel. Panels were to be installed on the roof of the tunnel to capture water coming off the ceiling that was degrading the railroad sub-base. By using 3D scanning, ACS created an image of the entire 3-mile long tunnel that allowed Granite Construction to determine where to excavate in order to place the new panels.

Aerial drones have also allowed ACS to tackle challenging projects, like the creation of a new cell for Mat-Su Central Landfill. Because a membrane is used to line the cell, it wasn’t possible for ACS to place stakes as they usually would. Instead, they used an aerial drone to take a series of images of the site along with strategic control targets to create a 3D map to guide the excavation.

“In the past, it would have taken multiple days to physically map the site,” Crow says.

As a member of Associated General Contractors of Alaska, ACS relies on the association’s website to track bid dates and project addenda.

“The Plans Room website is a tremendous resource,” Crow says. “The forecast meetings AGC holds yearly, as well as the lobbying efforts AGC has made for the whole industry, are wonderful.”