Northern Industrial Training

ver the years, I have heard a few people attempting to explain the challenges of fall protection by claiming that fall protection is “easy.” Having worked in fall protection for more than ten years across multiple industries—including logistics, defense contracting, parks and recreation, shipbuilding, oil and gas, and construction—I have learned one simple lesson: fall protection is ever-changing and far from easy.

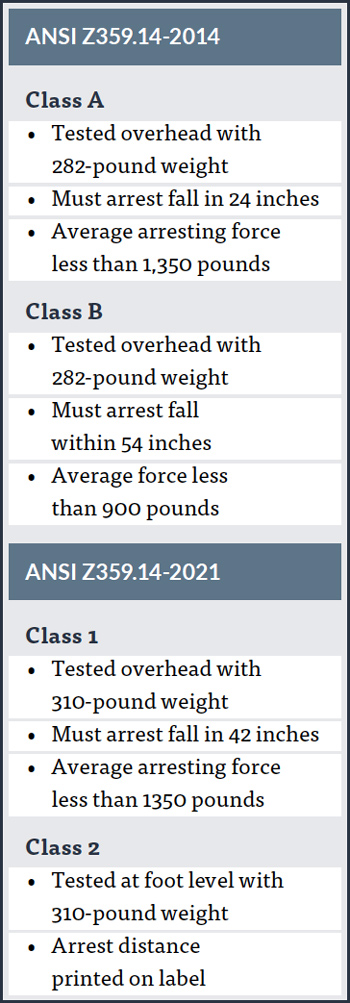

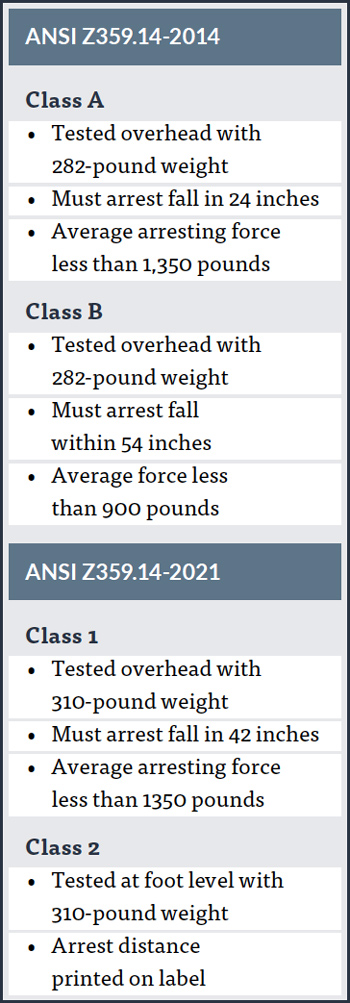

The revised standard ANSI Z359.14-2021 updates some long-needed language regarding SRL and will be fully adopted in February 2023. The last time ANSI published requirements for SRLs was in 2014 when SRLs were divided into two separate classes with various types. ANSI in 2014 established the requirement for two classes of SRL devices. Class A devices required a max arresting distance of 24 inches, and Class B devices required a max arresting distance of 54 inches. Along with Class A and B equipment, the 2014 ANSI standard touched on SRLs for Leading Edge Applications, or SRL-LE. Similar to the upcoming change, the 2014 requirement met the needs of the industry to understand work at height better. But several important factors were missing in the 2014 requirements.

Two major elements of the update were simplifying the types and classes of SRLs for the end user and improving marking and labeling systems. The updated language for SRL use will provide the end user with critical information in the field, making it easier to ensure proper use. The updated standard is an important change and will help protect end users from the worst-case scenario, using fall protection when working at height incorrectly and under the illusion they are safe (see fig. A).

The 2014 standard had Class A and B devices that could be anchored below the shoulders. Still, the only way an end user would know this information is in the event they were explicitly trained on that exact piece of gear or read every manual before committing to use. Both scenarios leave a fair amount of room for potential misuse of equipment.

Potential misuse of equipment only increases if the intended use of the equipment is not uniform across the board. With the 2014 update from ANSI, that was the case between multiple Class A and Class B SRLs.

With the upcoming change, one element is greatly simplified. Workers must tie a Class 1 SRL off-level with the harness dorsal D-ring or above, and in situations where that is not feasible, they must utilize a Class 2 SRL and may anchor below the dorsal D-ring if clearance is available. All Class 2 SRLs will be clearly labeled with clearance requirements moving forward. The change will allow the end user to verify the existing plan is correct and the fall arrest system will work as intended.

The change allows for much more rapid and simplified identification of whether or not the worker is utilizing the equipment correctly and will also help educate workers who have demonstrated a need for more understanding of the fall protection equipment used in a system.

The other major change in the requirement comes in the types of SRLs that will be made moving forward.

ANSI has broken SRLs down into three types:

- SRL – designed for standard or leading-edge applications

- SRL-P – mounted on a harness and designed for standard or leading-edge applications

- SRL-R – designed for retrieval or rescue functionality

The primary change with the three types is removing the SRL-LE designation for leading-edge applications. Leading edge devices that allow the worker to connect below the dorsal D-ring must be Class 2 devices. The Class 2 device will have a label printed directly on the product explaining the required clearances for the application. Setting up equipment with the updated language will be much easier in the long run. End users will have to memorize and remember less information. Confidence will ultimately increase because identifying if you are using the correct gear has been made much clearer for end users in the field.