Associated General

Contractors of Alaska

Associated General

Contractors of Alaska

8005 Schoon St.

Anchorage, AK 99518

907-561-5354

Fax: 907-562-6118

www.agcak.org

ChemTrack Alaska, Inc.

Pearl-Grace Pantaleone

HDR Alaska Inc.

Alicia Amberg

Associated General Contractors of Alaska

Christine A. White

R&M Consultants, Inc.

Heather Sottosanti

Big State Mechanical, LLC

Saigen Harris

F&W Construction, Inc.

Johnathon Storter

Meridian Management, Inc.

Annie Gardner

Knik Construction Co., Inc.

Tasha Anderson

Managing Editor

Rindi White

Editor

Monica Sterchi-Lowman

Art Director

Fulvia Lowe

Art Production

James K Brown

Graphic Designer

BUSINESS STAFF

Charles Bell

VP Sales & Marketing

907-257-2909 cbell@akbizmag.com

Janis J. Plume

Senior Account Manager

907-257-2917 janis@akbizmag.com

Christine Merki

Senior Account Manager

907-257-2911 cmerki@akbizmag.com

501 W. Northern LIghts Blvd., Ste 100

Anchorage, AK 99503

The Alaska Contractor is published by Alaska Business Publishing Co. Inc. for the Associated General Contractors of Alaska. Contents of the magazine are not necessarily endorsed by AGC of Alaska or Alaska Business Publishing Co. All rights reserved. Copyright 2024 by the Associated General Contractors of Alaska. For information about articles in this edition or for permission to reproduce any portion of it, contact Alaska Business Publishing Co.

Design by James K Brown

8005 Schoon St.

Anchorage, AK 99518

907-561-5354

Fax: 907-562-6118

www.agcak.org

ChemTrack Alaska, Inc.

Pearl-Grace Pantaleone

HDR Alaska Inc.

Alicia Amberg

Associated General Contractors of Alaska

Christine A. White

R&M Consultants, Inc.

Heather Sottosanti

Big State Mechanical, LLC

Saigen Harris

F&W Construction, Inc.

Johnathon Storter

Meridian Management, Inc.

Annie Gardner

Knik Construction Co., Inc.

Tasha Anderson

Managing Editor

Rindi White

Editor

Monica Sterchi-Lowman

Art Director

Fulvia Lowe

Art Production

James K Brown

Graphic Designer

BUSINESS STAFF

Charles Bell

VP Sales & Marketing

907-257-2909 cbell@akbizmag.com

Janis J. Plume

Senior Account Manager

907-257-2917 janis@akbizmag.com

Christine Merki

Senior Account Manager

907-257-2911 cmerki@akbizmag.com

501 W. Northern LIghts Blvd., Ste 100

Anchorage, AK 99503

The Alaska Contractor is published by Alaska Business Publishing Co. Inc. for the Associated General Contractors of Alaska. Contents of the magazine are not necessarily endorsed by AGC of Alaska or Alaska Business Publishing Co. All rights reserved. Copyright 2024 by the Associated General Contractors of Alaska. For information about articles in this edition or for permission to reproduce any portion of it, contact Alaska Business Publishing Co.

Design by James K Brown

AGC MEMBER

AGC MEMBER

Nodak Electric &

Construction, Inc.

$4,343,414

FAI Runway Lighting Rehabilitation

Clark Management

Clark Management

$1,771,240

Lathrop H.S. Kitchen Remodel

Callahan Construction Co.

Callahan Construction Co.

$1,500,000

YTA TA315 Reconfiguration

Midstate Equipment, Inc.

Midstate Equipment, Inc.

$585,329

Fairbanks Regional Public Health Center – Roof Replacement

A&A Roofing Company, Inc.

A&A Roofing Company, Inc.

$315,200

Fairbanks Residential Well System Installations

R&R Drilling

$224,883

Warrior Bivouac

Smallwood Creek, Inc.

$194,400

MCG Constructors, Inc.

$12,390,000

Water Distrbution System Replacement Project (Phases 1A, 1B and Add Alternates)

Scott’s Heating & Plumbing Services

$1,493,000

Capital Transit Facility Bus Charging Infrastructure

Alaska Electric, LLC

$1,464,240

JNU Jordan Creek Culvert Repair

Admiralty Construction, Inc.

$863,150

Poplar Avenue Reconstruction – Mendenhall Blvd. to Dogwood Ln.

North40 Construction Corporation

North40 Construction Corporation

$706,580

2024 Area Wide Paving Phase II

Secon-Aggpro

$690,953

Sitka Tribe of Alaska 2nd Floor Improvements Project

MCG Constructors, Inc.

$667,000

Homestead Park Reconstruction

Dawson Construction, Inc.

$641,467

Glenn/Richardson Highway Right of Way Reconciliation

AHTNA Construction & Primary Products Corporation

AHTNA Construction & Primary Products Corporation

$638,130

Meyer’s Chuck Harbor Replacement Float Procurement (Rebid)

Pacific Netting Products

$624,188

BRH Ground Floor, Flooring Abatement and Refinish

Far North Services, LLC

$498,200

Eyelet Court Reconstruction

Admiralty Construction, Inc.

$493,210

Wrangell High School Elevator Replacement

MCG Constructors, Inc.

$483,000

TNF Fire Sprinkler and Backflow Prevention Certification

North Star Fire Protection

$154,205

Culvert Tazlina Supply

Polar Supply Company

Polar Supply Company

$152,791

CRD Rock Crushing

Rock-N-Road Construction, Inc.

$119,250

QAP

QAP$44,664,163

OLI002 Road Repair

ASRC Earthworks, LLC

$34,084,500

Sand Point New Harbor A Float Project

Western Marine Construction, Inc.

Western Marine Construction, Inc.

$7,855,000

Harbor Master’s Office and Residence

Wolverine Supply, Inc.

$4,094,000

False Pass Airport Snow Removal Equipment Building

UIC Construction, LLC

$2,728,434

Northern Region Preservation Maintenance FFY2024

Jolt Construction & Traffic Maintenance, Inc.

Jolt Construction & Traffic Maintenance, Inc.

$1,731,600

Transit Center Boiler Replacement

Inlet Mechanical, Inc.

$456,715

Gulkana River Boat Launch Fencing

Steel Timber Fence Co.

$336,358

Purchase and Install Chain-Link Privacy Fencing for City Property

Alaska Fence Manufacturing and Supply, LLC

$180,800

Tuluksak Power Plant 2024 Generator #2 Replacement

Sturgeon Electric Co., Inc.

Sturgeon Electric Co., Inc.

$119,380

TBRD Upper Steelhead Road Storage and Decommissioning

Tongass Development, LLC

$114,000

QAP

QAP$29,350,750

ANC Taxiway R North & Taxilane U Improvements

Granite Construction Co.

Granite Construction Co.

$15,922,378

Valdez Airport Snow Removal Equipment and Deicing Materials Storage Building

F & W Construction Co., Inc.

F & W Construction Co., Inc.

$12,951,576

Bogard Rd. Pavement Preservation: Trunk Rd. to Wasilla-Fishhook Rd.

Granite Construction Co.

Granite Construction Co.

$11,392,654

Construct Central Landfill Site Improvements Phase 1

Orion Construction, Inc.

$6,621,800

Construct Gateway Visitor Center

Steppers Construction, Inc.

$6,462,378

Central Peninsula Landfill Leachate Infrastructure Phase II

Polar North Construction, LLC

$6,300,000

Construct Midway Street Road Improvements

Granite Construction Co.

Granite Construction Co.

$2,195,976

Chenega Bay Airport Lighting Improvements

Clark Management

Clark Management

$2,097,940

Caliber Construction

Caliber Construction$1,821,641

ANC Postmark Drive Repairs 2024

QAP

QAP

$989,444

Glenn Highway Milepost 86 Rockfall Mitigation

HiEx Construction, Inc.

HiEx Construction, Inc.

$725,248

Wasilla High School Boiler Replacement

CGC Services, LLC

CGC Services, LLC

$353,270

AFD Vehicle Maintenance Building Renovation

Orion Construction, Inc.

$329,400

Facility Support Center Roof C Replacement

Eklutna Construction & Maintenance, LLC

Eklutna Construction & Maintenance, LLC

$327,604

ANC Firing Range Maintenance

Central Environmental, Inc.

$325,721

Wasilla Pool Drain Repairs

Orion Construction, Inc.

$298,000

2024 Talkeetna Revetment and Dike Repair

Western Construction & Equipment, LLC

$292,475

Caliber Construction Alaska, LLC

Caliber Construction Alaska, LLC$273,575

Shelving Post Protectors and Netting at the Alaska Geologic Materials Center Warehouse

Material Flow & Conveyor Systems, Inc.

$255,860

Install Emergency Services Security Cameras

Raven Electric

$225,336

Provide Birch Tree/Elmore Limited Road Service Area Road Maintenance

Brownson Bros, LLC

$207,015

Port of Alaska Petroleum Cement Terminal Bull Rail Additions

CCL General Contracting

$194,000

Susitna Valley School Boiler Replacement

Valley Mechanical Contracting, Inc.

$172,950

Streambed Maintenance of Salmon Creek at Nautical Avenue

Andrews & Sons, LLC

Andrews & Sons, LLC

$134,328

Provide Cisco Calling Flex and Contact Center Renewal Services

SHI International Corp

$107,234

s Alaska’s construction industry on the brink of a new era of bold building? The Associated General Contractors, or AGC, of Alaska is a proudly nonpartisan association, but we have reason to be hopeful. With the incoming Trump administration promising a more business-friendly approach, the construction industry may soon see unprecedented opportunities. Here in Alaska, we’re also welcoming many new faces to the state legislature, some of whom are just beginning to understand the issues most important to our members. Now is the time for AGC members to connect, engage, and make our voices heard with these new policymakers.

AGC anticipates a streamlined approach to federal industry regulations and new opportunities in workforce development, immigration reform, tax policy, and infrastructure funding. With the new administration, AGC expects regulatory changes to begin as soon as January 2025, particularly through executive orders addressing permitting, workforce development, and immigration reform—issues with significant impact on Alaska’s unique challenges. AGC of Alaska’s advocacy efforts will focus on ensuring these federal changes support, rather than hinder, regional projects.

In total, $16 billion was spent on this election—the most expensive in history. More than 155 million Americans voted, showing their unprecedented desire to be heard on a variety of issues.

The AGC PAC enjoyed a particularly successful year, achieving a 91% success rate in backing pro-construction candidates. The national AGC PAC raised more than $1.2 million to support both Democrats and Republicans who align with industry priorities.

We urge every member to take part in AGC’s advocacy efforts in 2025. Whether attending legislative meetings, contributing to the Construction Advocacy Fund, or responding to Action Alerts, each member’s involvement strengthens our industry’s position.

- President: Saigen Harris, F & W Construction

- Vice President: Carrie Jokiel, ChemTrack Alaska

- Secretary: Luke Blomfield, Davis Constructors & Engineers

- Treasurer: Toby Drake, Drake Construction

- Contractor at Large: Chrys Fleming, Alcan Electrical & Engineering

- Associate Member: Randy Johnson, Spenard Builders Supply

- Immediate Past President: Marcus Trivette, Brice, Inc.

Backed by a dedicated board of directors, these leaders bring decades of combined experience, ready to advance Alaska’s construction industry. Thank you all for your ongoing engagement and dedication to making 2025 our best year yet!

Branden Roybal, Owner

220 Slater Dr., Fairbanks AK 99701

Phone: 907-371-9868

branden@roybalconstruction.com

roybalconstruction.com

Roybal Construction, LLC is a general contractor specializing in residential and commercial construction and renovations.

TMG Wall Systems

Tyler Moore, CEO

240 E. Tudor Rd., Suite 210, Anchorage, AK 99503

Phone: 907-440-2308

Tyler@tmgwallsystems.com

tmgwallsystems.com

TMG Wall Systems is a commercial drywall contractor specializing in drywall installation and finishing along with ancillary services that complement the gypsum wall board scope of work. TMG Wall Systems’ core competency is in multi-family housing and mixed-use developments.

Jonathan Parrish, President

PO Box 240523, Anchorage, AK 99524

Phone: 907-360-8436

currentelectricalak@gmail.com

currentelectricak.com

Current Electric, LLC is an Alaskan family-owned and -operated electrical business serving the entire state. Operation began in 2022 working commercial, industrial, residential, and fire alarm projects.

Terra Land Management, LLC

Christian Erickson, Owner

2944 Richardson Hwy. Ste. D, North Pole, AK 99705

Phone: 907-378-7959

terralandmngmt@gmail.com

Terra Land Management, LLC offers premier hydro-axing and site-preparation services in Alaska’s Interior region.

DBA: Bond Babes USA

Lynnette Wood, Owner

Jaden Sherman, Director of Operations

4730 Business Park Blvd., Anchorage, AK 99503

Phone: 1-800-991-6297

sales@bondbabesusa.com

bondbabesusa.com

Bond Babes USA is a woman-owned business enterprise (WBE) that specializes in providing quick, reliable surety and fidelity bonds tailored to meet business and industry needs. Our cheeky and fun, client-focused process ensures you’re back to work fast, worry-free, and fully bonded!

Black & Veatch

Richard Hancock, Federal Account Director

11401 Lamar Ave., Overland Park, KS 66211

Phone: 703-395-1281

HancockR@bv.com

bv.com

Black & Veatch is an architecture and engineering firm specializing in full-service design and construction management to support military, civil works/water, energy/power, and telecommunications.

Brite Ideas Project Consulting

Brite Niezek, Managing Member, Lead Consultant

247 S. Alaska St., Palmer, AK 99645

Phone: 907-707-3875

info@briteideasconsulting.com

briteideasconsulting.com

Brite Ideas Consulting is a DBE and women-owned business that provides expert project scheduling, project controls, and project management support to your organization. Our consultants have extensive experience in the areas of proposal development, critical path construction scheduling, earned value management, and contract administration.

Fremontii, LLC

John Mortensen, President

PO Box 3288, Homer, AK 99603

Phone: 907-756-3104

john.mortensen@fremontii.com

fremontii.com

Fremontii, LLC provides commercial construction project management, owner’s representation, and consulting services.

Horizon Trek, LLC

Wendy Claussen, Owner/Senior Advisor

6720 Waller Cir., Anchorage, AK 99502

Phone: 907-952-0808

wendy@horizon-trek.com

horizon-trek.com

Horizon Trek, LLC is a full-service business advisory firm that assists privately held businesses through ownership transitions.

Horst Expediting & Remote Operations

Josh Horst, President

3540 Holt Rd., Fairbanks, AK 99701

Phone: 907-479-4376

josh@horstexpediting.com

horstexpediting.com

Detailed and reliable logistics services including procurement, consolidation, hot shot, and last-mile delivery to job sites or air carriers accessible from Fairbanks. Remote temporary crew camps, up to twenty-four persons, constructed, maintained, and staffed to include catering, housekeeping, and camp management. We are a team of problem solvers working hard to help our customers complete their projects.

*Referred by Amy Cook, TOTE Maritime Alaska, Inc

Lennon Crane

Scott Lennon, Vice President

17131 Beaton Rd. SW, Monroe, WA 98272

Phone: 360-863-0333

scott@lennoncrane.com

lennoncrane.com

Since 1975, Lennon Crane and Equipment Company has safely and successfully served its customers throughout the western United States and provinces throughout Canada. Lennon Crane’s core business is “full-service bare rental” of cranes which provides unmatched service, project value, and flexibility to our customers with a fleet of more than fifty rough terrain and telescopic boom crawler cranes from 35 ton to 160 ton. Lennon Crane is now an authorized Tadano Distributor for new crane sales of the Tadano line-up of cranes including All Terrain (AC), Rough Terrain (GR), Telescopic Crawler (GTC), and Truck Cranes (GT) throughout the Pacific Northwest. The Lennon Crane team is dedicated in providing our customers service excellence in product support and parts.

Old Second National Bank

Scott Armitage, Vice President,

Equipment Finance Division

37 S. River St., Aurora IL, 60506

Phone: 208-602-6424

sarmitage@oldsecond.com

oldsecond.com/business-banking/equipment-finance

Old Second National Bank offers heavy equipment financing.

Olsen Creek, LLC

Tyler Loken, Manager

5400 Eielson St., Anchorage, AK 99518

Phone: 907-868-8880

info@olsoncreekllc.com

olsoncreekllc.com

Olson Creek, LLC specializes in lodging and equipment rental services.

*Referred by Luke Blomfield, Davis Constructors & Engineers, Inc.

QA Services, Inc.

Ty Amberg, Owner

5610 Silverado Way, Anchorage, AK 99518

Phone: 907-522-1969

inspections@qaservicesak.net

qaservicesak.net

QA Services, Inc. is an Alaskan-owned and -operated company providing fully qualified nondestructive and destructive inspection, consulting, industrial inspection and quality surveillance, and assurance services. Services include assembly, welding, special inspections, quality-control plan review and development, and industrial coatings for all facets of steel buildings, bridges, tanks, pipelines, and steel structures at both shop and field locations.

Trygg Air Alaska

Chris Klosterman, Owner/Director of Operations

3901 Aircraft Dr., Anchorage, AK 99502

Phone: 907-350-8675

Info@tryggair.com

tryggair.com

Commercial air charter for passengers and freight statewide. Various configurations of aircraft to support various industries.

*Referred by Brennan Walsh, STG, Inc.

VP Promos

Jaxon Thiemann, National Accounts Manager

Steven Dodson, Owner

PO Box 525, Clam Gulch, AK 99568

Phone: 907-252-7458

jaxon@vp-promos.com

vp-promos.com

VP Promos offers screen-printing and embroidery, custom company apparel, company logoed merchandise, and branded PPE (safety vests, hard hats, and more).

ith record-breaking attendance, fantastic weather, and exceptional programming, the 2024 Associated General Contractors, or AGC, of Alaska Annual Conference was “far out.”

The event kicked off with a well-attended, three-hour update from the Alaska Department of Transportation and Public Facilities and included a range of other presentations, from Dr. Charlie Cartwright’s management symposium focusing on creating a sense of belonging in the workplace to talks about using technology to make your job easier, using digital twins, and drones in construction. Senator Lisa Murkowski delivered a speech encapsulating her hopes that the upcoming Republican-majority led Congress will allow significant progress in developing resources, while expressing concern that the state should do more to work with the federal government on issues such as transportation and construction. The US Army Corps of Engineers and North Slope oil major Santos discussed upcoming contracting opportunities. On Saturday evening it was time to bring out the gold chains and sequins and do the “Hard Hat Hustle,” celebrating the end of a busy and successful construction season.

- Brice, Inc.

- Cruz Construction, Inc.

- Davis Constructors & Engineers, Inc.

- KLEBS Mechanical, Inc.

- Spenard Builders Supply

Silver Sponsors

- Anchorage Sand & Gravel Co., Inc.

- Davis Block & Concrete

- Granite Construction Company

- Great Northwest, Inc.

- STG Pacific LLC

Bronze Sponsors

- GHEMM Company, LLC

- JD Steel Co., Inc.

- Lynden

- Polar Supply Company

- Swalling General Contractors, LLC

Steel Sponsors

- BDO USA

- ChemTrack Alaska, Inc.

- Denali Drilling

- Fullford Electric, Inc.

- Knik Construction Co., Inc.

- Loken Construction, LLC

- Loken Crane, Rigging & Transport, LLC

- Malcolm Drilling Co., Inc.

- Olson Creek, LLC

- PND Engineers, Inc.

- STG, Inc.

- ConocoPhillips Alaska

- Construction Machinery Industrial

- F & W Construction Co., Inc.

- First National Bank Alaska

- Marsh McLennan Agency

- Northrim Bank

- Parker, Smith & Feek, LLC.

Additional Event Sponsors

- Alaska Industrial Development and Export Authority

- Black & Veatch

- The Brandon Skinner Group, PC

- Denali Drilling, Inc.

- Denali Industrial Supply, Inc.

- Drake Construction, Inc.

- Iron, Inc.

- KLEBS Mechanical, Inc.

- KUNA Engineering

- Meridian Management, Inc.

- North Star Equipment Services

- Samson Tug & Barge

- Spenard Builders Supply

- TOTE Maritime Alaska, Inc.

- Zurich Surety

Raising the Bar

or more than two decades, Alaska Crane has been a cornerstone of the state’s heavy-lift industry. Since the company was established in 2001, Alaska Crane company leaders have dedicated themselves to meeting the needs of the company’s Alaska clients, specializing in high-quality crane service.

“We’ve been pulled into many different projects over the years, from railroad bridges to lifting ships out of the water, showcasing the versatility and importance of our work across the state,” says Brennan Walsh, president of Alaska Crane and STG Incorporated, both of which are owned by Calista Corporation.

With a fleet capable of handling loads ranging from 28 to 660 tons and crane boom lengths exceeding 400 feet, Alaska Crane prides itself on its robust arctic-grade capabilities, which allow its equipment to perform under the most extreme conditions.

“Our entire fleet of arctic-tough cranes can brave temperatures as low as -40°F,” says Walsh, “making these winter workhorses ideal for year-round, cold-weather operations across Alaska.”

Although it operates out of Anchorage, Alaska Crane serves every region in the state. It’s equipped to tackle both contract-based projects and call-out services that are tailored to client needs. The company employs a small but highly skilled team, averaging between six and ten employees, which allows for a personalized approach to each project, Walsh says.

“I’m always impressed with the skill sets and capabilities of our team,” says Walsh. “Being a small crane service company, they are exposed to a wide array of projects and challenges.”

President, Alaska Crane

Above, Alaska Crane’s equipment stands ready to support renewable energy efforts at the Fire Island Wind project.

Views from the ground (left and below) detail the precision required by operators to use its Liebherr LTM 1500, a 600-ton capacity all-terrain crane, to replace a gearbox on a wind turbine for the project, a testament to the team’s technical expertise.

Reflecting on his journey, Dooley notes, “It’s been a long career path for me, but I think I’m finally in a position where I could stay at home.”

“Our role was to provide the crane support for GE’s technicians to perform maintenance on two turbines, including replacing gearboxes to prevent potential internal failures,” says Dooley.

Alaska Crane mobilized in August and faced multiple weather days due to 25 to 30 mile per hour winds, which created hazardous conditions for moving equipment across the Cook Inlet.

Despite the challenges, Alaska Crane completed the project by mid-September, which demonstrated its adaptability and commitment to safety, says Dooley.

“Working closely with Fire Island Wind, GE, and Alaska Crane, we maintained constant communication to ensure everyone was on the same page, working towards completing the job efficiently,” says Dooley.

Chris Jimenez, senior operations manager at CIRI, had nothing but positive feedback for the work Alaska Crane performed on Fire Island.

“Alaska Crane’s team and equipment were essential to the success of the Fire Island Wind project, handling large, heavy components with ease,” says Jimenez.

Despite high winds, Alaska Crane’s careful planning and execution ensured minimal impact on the project timeline. Jimenez praised Alaska Crane’s strict protocols.

“Alaska Crane’s strict safety protocols created a secure environment on-site and kept the project on track without delays. Working with Alaska Crane’s operators and riggers was a positive experience. Their high level of professionalism and flexibility made a real difference in project execution.”

The company’s focus on safety earned it an Excellence in Safety award at the 2024 Associated General Contractors of Alaska annual convention in November. Read more about the award on page 50.

“Our commitment to skill sets and safety has allowed us to thrive for over twenty years,” says Walsh.

Some key projects include extending the Sitka Blue Lake Dam in 2013, installing railroad and highway bridges, lifting ships out of the water for inspections, helping recover aircraft that traveled off runways, and changing out jumbo jet engines at Ted Stevens Anchorage International Airport. Sometimes Alaska Crane sets down hot tub units, too, Walsh says.

“It’s a pretty wide variety of projects we get involved with, but we try to approach them all the same, whether it’s a hot tub unit or a bridge girder. From a planning and safety perspective, we try to get in, get out, and bring value to the customer and the job.”

he Associated General Contractors, or AGC, of Alaska is a member-driven, member-supported organization. In other words, without input from members, it’s not effective. That input comes in many forms, but much of it happens around committee tables, where AGC leaders work together to tackle issues of import to members. AGC board members bring their own experience, as well as input gleaned from other industry leaders, to the table when discussing issues such as workers’ compensation or workforce development tools. AGC of Alaska would like to welcome the 2024/2025 executive board and all the members of its board of directors as we embark on a new year of service.

Saigen Harris, President

F&W Construction Co., Inc.

Harris’ involvement with AGC began in high school, participating in AGC National scholarship opportunities and conferences. This involvement sparked her desire to form the AGC of Alaska Construction Leadership Council, or CLC, in 2014. Since the formation of Alaska’s CLC, Harris has participated as a steering committee member for the AGC National Construction Leadership Council. Harris currently serves as a member of the AGC National Business Development Forum.

Harris enjoys spending time in the mountains with her husband Nathan, daughter Magnolia, and their dog, Marshall.

Carrie Jokiel, Vice President

ChemTrack Alaska, Inc.

Jokiel attended the University of New Hampshire, or UNH, on an ice hockey scholarship. During her time there she received a Bachelor of Science in Kinesiology, won a national championship, and captained her team her junior and senior year.

After graduating she worked for NBC Sports in New York City and was hired to work the 2002 Winter Olympics in Salt Lake City. Upon returning home to Anchorage, she worked at the local sports arena and finished her MBA from UAA. She then began working at ChemTrack and finished her masters of science in project management, or MSPM, also from UAA.

Jokiel is active on the AGC Board of Directors. She is a mentor for the Women’s Power League of Alaska, a new nonprofit seeking to champion future and existing leaders in the 49th state through mentorship, professional development, and community building. Jokiel was a board member of the YWCA Alaska where she served as Board President for two years. She is also a member of Women Impacting Public Policy, or WIPP, the Society of American Military Engineers, the National Contract Management Association, and is an Ambassador for Women’s Ice Hockey in the Fast and Female International Program. In 2018, Jokiel was awarded the Enterprising Women of the Year award for her company’s revenue category. In 2016, she was inducted into the Sports Hall of Fame at the University of New Hampshire and in 2014 was named one of Alaska Journal of Commerce’s Top Forty Under 40.

Jokiel was born and raised in Anchorage and is still active in the hockey community, playing and coaching. She enjoys spending as much time as possible in Girdwood skiing, running, and enjoying the mountain town lifestyle. Most importantly she is the proud mom of a little lady named Will, named for her incredibly strong German Oma, Wilhelmina.

Luke Blomfield, Secretary

Davis Constructors & Engineers, Inc.

During his professional career, Blomfield has achieved a few noteworthy accomplishments. He is married to a wonderful woman and has two stellar children; he was invited to speak at the Project Management Institute Global Congress presenting his master’s thesis; he was named one of Alaska Journal of Commerce’s Top Forty Under 40; he sits on the UAA Construction Management Department Advisory Committee; and he is a member of the Anchorage Museum Board of Directors.

Drake Construction, Inc.

Drake and his wife, Amber, have three daughters: Callan, Teigan, and Mairyn. A Doyon shareholder, Drake serves on the Alaska Technical Center Advisory Board in Kotzebue as well as AGC’s Department of Transportation Committee and its Sustainable Budget Task Force. In his spare time, he enjoys outdoor activities such as fat tire biking, snowmachining, and golf.

Alcan Electrical & Engineering

Recognizing his potential, Alcan’s leadership provided him with further development opportunities, which included leadership courses through the National Electrical Contractors Association and training through Firestone Consultants’ Leadership Academy. Armed with an Electrical Administrator’s License, Fleming stepped into project management roles and soon became indispensable to Alcan’s operations. His accomplishments include managing major projects such as the Solid Waste Services Central Transfer Station in Anchorage and the Long-Range Discrimination Radar at Clear, both of which required meticulous planning and coordination with top partners like Lockheed Martin and Davis Constructors & Engineers.

Fleming’s dedication and vision eventually led him to partner with Jesse Hale and Sage Bringmann to acquire Alcan, where he now serves as president. Under his leadership, Alcan has successfully delivered some of Alaska’s largest and most complex electrical projects. Known for his focus on company culture, Fleming emphasizes teamwork and employee recognition as core values within the organization.

Beyond his professional achievements, Fleming is a proud Alaskan who enjoys spending time with his family, supporting his kids in their sports, and exploring the outdoors during Alaska’s vibrant summers. His dedication to his team, community, and industry makes him a respected leader in Alaska’s construction landscape.

Spenard Builders Supply

Brice, Inc.

Trivette holds professional registrations as a civil and environmental engineer and serves on the UAF Civil and Environmental Engineering Advisory Board. He is passionate about promoting the construction industry, education, and the opportunities the industry affords its workforce.

He calls Fairbanks home, along with his wife, Jodee, and their two sons, Owen and Rylan.

AGC Board of Directors

Executive Board

Saigen Harris

President

F&W Construction Co. Inc.

Carrie Jokiel

Vice President

ChemTrack Alaska, Inc.

Luke Blomfield

Secretary

Davis Constructors & Engineers

Toby Drake

Treasurer

Drake Construction, Inc.

Chrys Fleming

Contractor-at-Large

Alcan Electrical & Engineering

Randy Johnson

Associate Member

Spenard Builders Supply

Marcus Trivette

Immediate Past President

Brice, Inc.

Mike Andersen

DAMA Industrial, LLC

Aaron Bartel

B. C. Excavating, LLC

Matt Chaco

GHEMM Company, LLC

Robert Champion

Brice Pacific, LLC.

Amy Cook

TOTE Maritime Alaska, Inc.

Kirk Currey

CMI, LLC

Regina Davis

Davis Block & Concrete

Aaron Finney

Shoreside Petroleum, Inc.

Mike T. Gould

Excel Construction, Inc.

Troy Gray

Knik Construction Co., Inc.

Darrin Hansen

Kiewit

Sean Hickel

Roger Hickel Contracting, Inc.

Kris Jensen

Colaska, Inc.

Randee Johnson

SafeLogic Alaska, LLC

Joe Jolley

Cornerstone General Contractors

Matt Ketchum

K&H Civil Constructors, LLC

Mike Klebs

KLEBS Mechanical, Inc.

Sarah Klebs

CGC Services, LLC

Dax Lauwers

Marsh McLennan Agency

Tyler Loken

Loken Construction LLC

Travis Malin

HC Contractors, LLC

Jeff Miller

Cruz Construction, Inc.

American Marine Corporation

Ron Pilcher

Denali Drilling, Inc.

Steve Rowe

Swalling General Contractors

Kiersten Russell

Northrim Bank

Jennifer Schrage

Signature Land Services

Heather Sottosanti

Big State Mechanical, LLC

Chase Swalling

STG Pacific LLC

Matt Thon

Parker, Smith & Feek, LLC

Marty Thurman

Granite Construction Company

Scott Vierra

North Star Equipment Services

Brennan Walsh

STG, Inc.

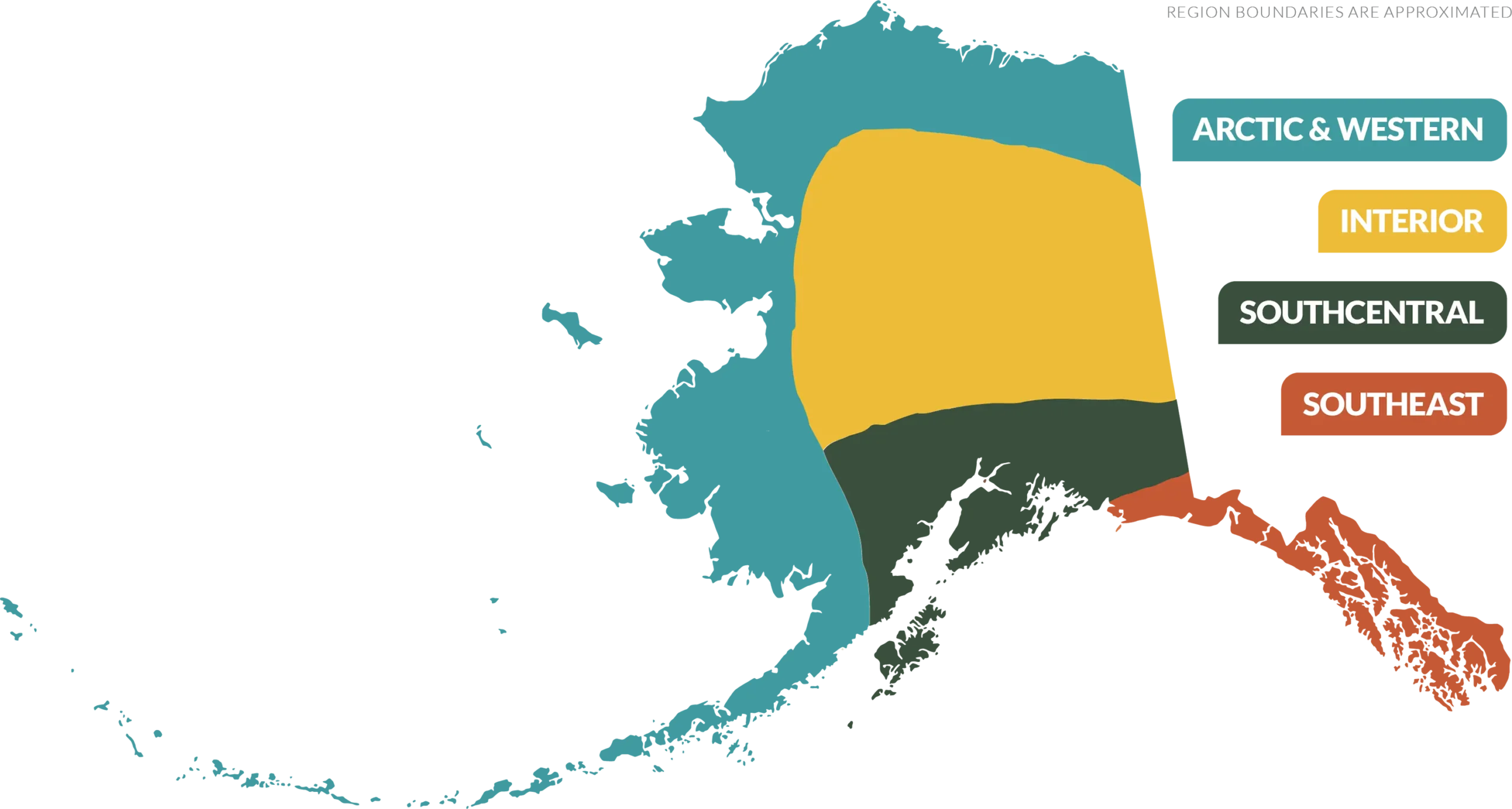

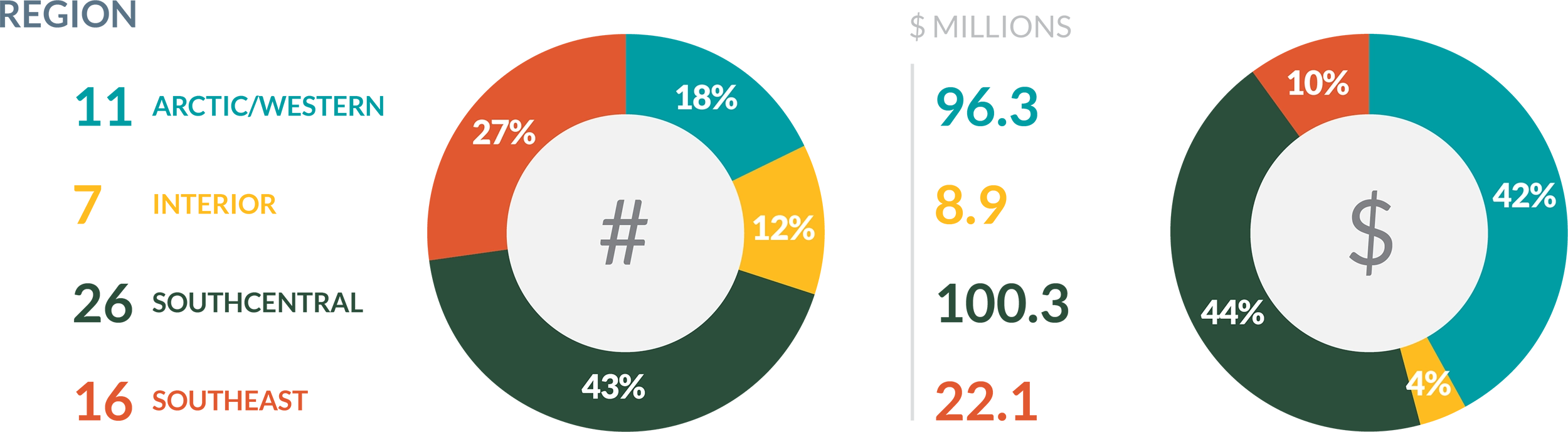

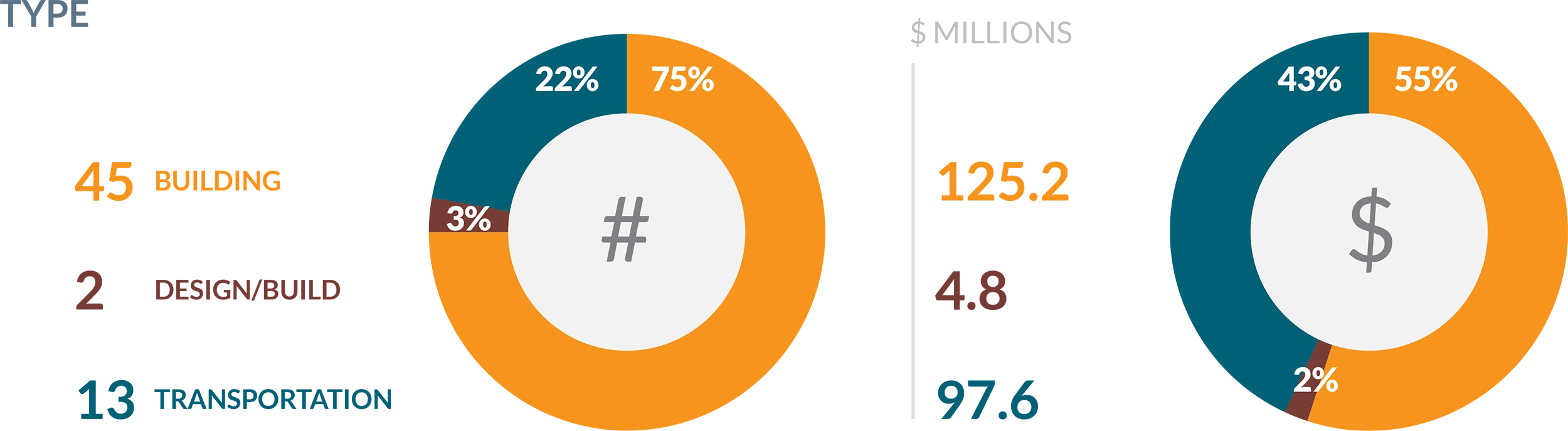

n 2024 the Alaska Statewide Transportation Improvement Program, or STIP, was initially rejected by the federal government, a rare and unanticipated roadblock as the state and contractors were prepping for upcoming public projects. While the STIP was later approved, this early difficulty led to a lower-than-anticipated August Redistribution, funding that the Federal Highway Administration, or FHWA, distributes each August.

To respond to construction industry concerns, the Alaska Department of Transportation and Public Facilities, or DOT&PF, updated Associated General Contractors, or AGC, of Alaska members at the 2024 AGC of Alaska Annual Conference about the STIP process in the future, construction projects in the coming year, and other project opportunities on the horizon.

It covers all system improvements for which partial or full FHWA funding is approved and expected to be received within the duration of the four-year plan. The STIP doesn’t fund airports or non-ferry-related ports and harbors that receive dollars from other sources.

In most years, the STIP is submitted and approved with findings or corrections. This year, the process didn’t go as smoothly. Though DOT&PF presented the STIP in the same format as previous years, the plan was initially rejected in February. After DOT&PF made corrections to its initial submission, the plan received partial approval in March, but DOT&PF says FHWA did not process the amendment fully until September, after funding decisions for the annual August Redistribution were already made. That delayed decision left Alaska with only $19 million in the August Redistribution, much lower than the $71.4 million the state would have been eligible to receive had the amendment been approved prior to the August Redistribution.

The catch is that the funds have to be obligated by the end of September, and the funding is only approved if the request fits into one of about sixty-five “pots” of money, each pot representing different spending eligibility criteria.

The process gives states a chance to fund additional projects, and generally Alaska does well, DOT&PF leaders say, typically even outperforming many other states. But this year, DOT&PF Administrative Services Division Director Dom Pannone told AGC members, eleven of the projects submitted to use the August Redistribution funds were rejected: seven of those because the project budgets had increased enough that moving forward on the project now required a STIP amendment.

Commissioner, Alaska Department of Transportation & Public Facilities

Alaska had submitted the amendment requests, Pannone said, but they had not yet been approved in August.

Ryan Anderson, DOT&PF commissioner, attributes the difficulties with STIP funding and the August Redistribution to federal staff changes, additional scrutiny of Alaska’s transportation spending, and lack of clarity on federal requirements.

“You can read all the correspondence online and the progress we made,” says Anderson. “But some projects like the Chena Flood Plain Bridges were cut because we don’t interpret boundary regulations the same way as our federal partners. We’re struggling to get the details and descriptions we need to resolve things.”

It’s a balance, Anderson told the audience of contractors.

“We definitely don’t want to delay projects over fights with the federal government, but there are certain things that, we believe, if we don’t stand up for ourselves and say, hey, we have to have a certain amount of flexibility in the state of Alaska… it’s going to affect us in the future,” he said.

Anderson says many contractors feel like they aren’t seeing the backlog of work for next year, or they worry about further delays to existing projects due to funding. However, funding for DOT&PF projects includes other programs and grants outside the STIP. Though the August Redistribution was only $19 million, this is just a piece of the overall $650 million in federally funded highway projects Alaska acquired in fiscal year 2024. And $300 million more from the Federal Aviation Administration, or FAA, was awarded for aviation projects, with other projects receiving funds from the State of Alaska capital budget.

Anderson says $100 million in new projects is a good start. “We want to deliver more projects earlier in the year, prepare better bids, and stay focused to get project work to the street as early as possible.”

“We’ve asked AGC leadership to give us some targets as we look at these challenges and program by year,” said Anderson during his presentation. “We’re looking for input on what types of projects, how to manage the geographic spread, and what size is preferable. What’s the right spot for the industry?”

Though the STIP has taken the spotlight recently, FAA funding also experienced disruption as the FAA Reauthorization Act of 2018 ended in fiscal year 2023, the new Reauthorization Act was delayed and has been funded with continuing resolutions, which slows down the roll-out of the program.

Troy LaRue, DOT&PF operations manager for the Division of Statewide Aviation, told AGC members that without reauthorization funding the entire program, the FAA relied on continuing resolutions. That made it difficult to determine when money would be available for projects.

Commissioner, Alaska Department of Transportation & Public Facilities

“If you look at the grant timeline, you can see that we were really hit hard by how the FAA soft-rolled them out,” said LaRue. “We’re talking to them at great lengths and seeing how we can change that.”

According to LaRue, another source of recent funding restriction is the Airport Improvement Program, or AIP, Handbook. The handbook provides guidance to FAA staff about administering the AIP program. He said revisions rendered several previously accepted projects ineligible and put more of the funding burden on the state programs. Since the changes were made without public process, DOT&PF is working with FAA to make corrections.

LaRue says the next two years of the Airport Capital Improvement Program, or ACIP, look solid, but the third year will depend on the bid openings from the first two seasons. DOT&PF attempts to program the Airport Capital Improvement Plan five years out. Overall, he told AGC members that he feels the department has a fairly good grasp of where it’s going with statewide aviation.

“We did open up a project for over $3 million each year to put back into transportation workforce development,” reported Keith. “We will continue to have conversations with AGC, and we look forward to discussing what we can do together to increase our workforce.”

To better keep contractors informed about DOT&PF projects, the department has developed an online dashboard that displays a tentative schedule. It allows users to search projects by cost, region, and time. To view the schedule, visit dot.alaska.gov/tasdashboard/.

Regional leaders wrapped up their look forward by highlighting projects slated for 2025, an outlook that included more than 100 road, airport, facility, and Alaska Marine Highway System projects in the works or scheduled to come up for bid in the next year to year and a half. Chris Goins, Southcoast Regional Director, also thanked contractors who helped clean up the more than twelve disasters over the last year, particularly a spate of recent disasters in Southeast that included a landslide, office fire, and significant culvert collapse, all of which occurred in the span of just a few hours.

“Contractors like you showed up. Some of you, I didn’t have to call. You just showed up with equipment and said, ‘I’m ready to work, what do you need me to do?’” said Goins.

Commissioner, Alaska Department of Transportation & Public Facilities

“We all know how important this program is for the construction industry,” says Anderson. “This is a two-way partnership with AGC. We aren’t shying away from this issue even when things are tough and complicated.”

Alicia Amberg, Executive Director for AGC of Alaska, says AGC members appreciated the entire DOT&PF leadership team taking the time to present on upcoming challenges and opportunities while answering some tough but valid questions from members on the overall program.

“We continue to engage in dialogue with the administration and DOT to understand better the construction program in the upcoming year, as well as concerns surrounding FHWA and the STIP,” she says.

Contractor:

STG, Inc.

Project:

Utqiaġvik Airport New Telecommunications Tower Facility

Photos provided by STG, Inc.

Contractor:

ChemTrack Alaska, Inc.

Project:

Environmental Remediation Debris Removal Services at Former Cape Prince of Wales Naval Field Station

Photos provided by ChemTrack

Contractor:

Alcan Electrical & Engineering

Project:

Yukon-Kuskokwim Qavartarvik Customer Lodging Building, Bethel

Photos provided by Alcan Electrical & Engineering

Contractor:

Brice, Inc.

Project:

St. Mary’s Airport Improvement Project

Photos provided by Brice, Inc.

Contractor:

Brice, Inc.

Project:

St. Mary’s Airport Improvement Project

Photos provided by Brice, Inc.

Contractor:

STG Pacific LLC

Project:

STG Pacific Skilak Lake Road Aquatic Organism Passage Improvements

Photos provided by STG Pacific LLC

Contractor:

STG Pacific LLC

Project:

STG Pacific Skilak Lake Road Aquatic Organism Passage Improvements

Photos provided by STG Pacific LLC

Contractor:

Cruz Construction, Inc.

Project:

Shageluk Airport Access Road Improvements

Photos provided by Cruz Construction, Inc.

Contractor:

Cruz Construction, Inc.

Project:

Atqasuk Airport Resurfacing Project

Photos provided by Cruz Construction, Inc.

Contractor:

Cruz Construction, Inc.

Project:

Atqasuk Airport Resurfacing Project

Photos provided by Cruz Construction, Inc.

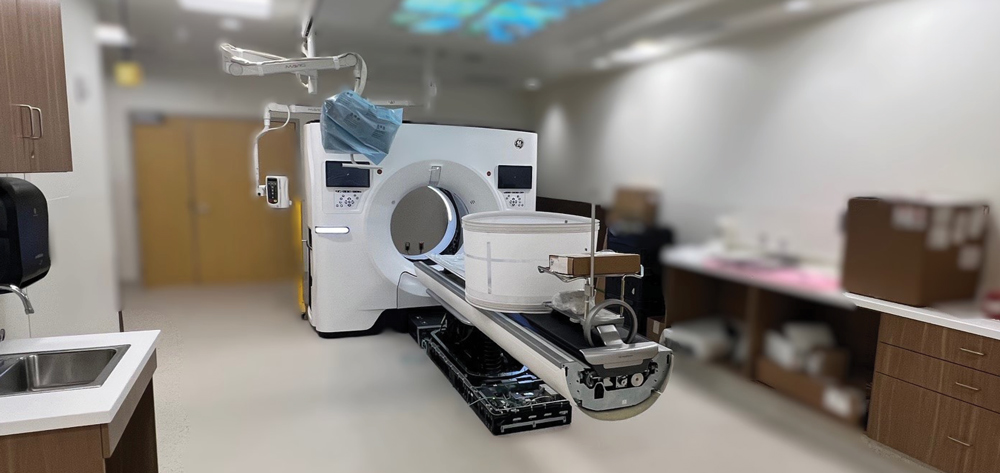

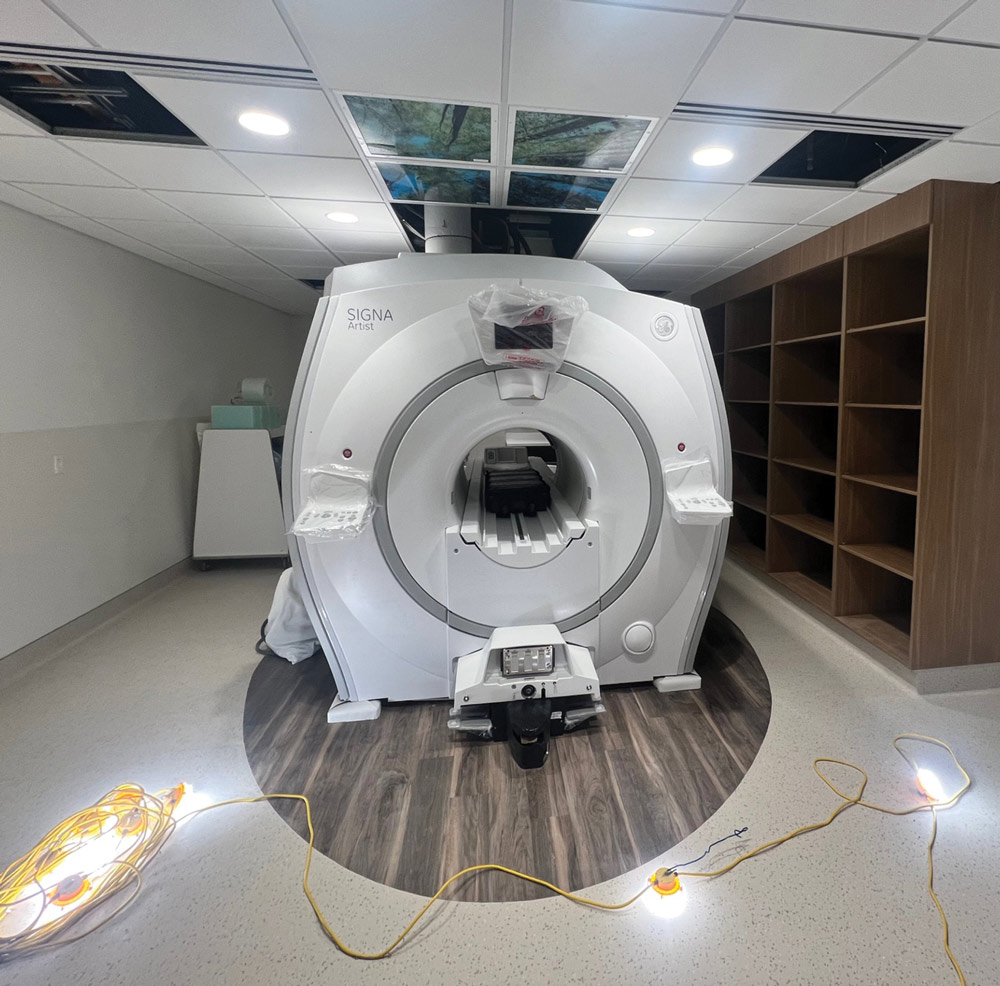

Contractor:

Roger Hickel Contracting, Inc.

Project:

Alaska Native Medical Center MRI and CT Replacement for Alaska Native Tribal Health Consortium

Photos provided by Roger Hickel Contracting, Inc.

Contractor:

Ahtna Infrastructure & Technologies, LLC

Project:

Akiuk School Fire Cleanup

Photos provided by Ahtna Infrastructure & Technologies, LLC

Contractor:

ASKW-Davis, LLC.

Project:

Yukon-Kuskokwim Qavartarvik Customer Lodging Building, Bethel

Photos provided by ASKW-Davis, LLC

Contractor:

ASKW-Davis, LLC.

Project:

Yukon-Kuskokwim Qavartarvik Customer Lodging Building, Bethel

Photos provided by ASKW-Davis, LLC

ivil and government jobs provide the bulk workload for many contractors. From infrastructure projects to office buildings to waste management and more, federal, state, and local governments are forever in need of getting projects done. And for construction and contracting firms, being able to successfully execute these jobs requires completing a lot of paperwork.

This is where Tamie Taylor, founder of Taylored Business Solutions, steps in.

“Government jobs are paperwork intensive,” Taylor says. “It is imperative that your pre-con submittals and buy-out [are] completed timely to successfully kick off a project. You’ve got to have somebody preparing and reviewing those submittals and making sure that they’re done. Because you can’t start digging until you have a plan that is submitted and approved. That’s the part that I was wanting to take off of their plate and/or help guide them.”

Taylor also helps contractors obtain the staffing they need to keep the job going. “If you don’t have the people, I can temporarily supplement and assist you in hiring them, so that you know we can put them in the plans that have to be submitted.”

Taylor doesn’t stop there. She says she often finds herself guiding clients long after they have broken ground and started work. “If a project is in trouble, then I’m going on site,” she says. “I’m being the project manager, superintendent, or QCM (quality control manager) and digging into the project to figure out how we’re going to get the work done.”

“I had a boss that saw my ability and basically came up to me and said, ‘You can do whatever you want to in this industry. You just tell me how I can help you get there’,” she recalls.

She told him she wanted to be on location at construction projects, so that’s where he sent her.

“I was in the field being a laborer and then was in the job site trailer, being like a project engineer or a contract administrator, doing submittals, helping the project manager,” she says.

By making herself available, she became indispensable, and her knowledge of the industry grew rapidly.

This brought her north in 1989, when the same contractor took a job here and asked her to come work as a contract administrator.

“He called me when I was in Colorado and said, ‘How can I get you to come to Alaska?’”

She stayed and founded Taylored Business Solutions in 2013.

“I felt that there was a need in small businesses helping them navigate the government contracting world,” she explains.

She saw contractors struggle with the paperwork and process necessary to successfully start and manage government contracts and decided with her knowledge and experience that she could help. “I saw the need and wanted to be the fixer.”

The business took off immediately. “When I put the word out there that I was willing to do this, I had contractors calling me all the time.”

Project Manager, M2C1 Construction & Engineering

Jim Bennett, a project manager with M2C1 Construction & Engineering, has worked with Taylor and says she “brings an incredible blend of skill and dedication to every project. Her attention to detail and collaborative approach make working with her a rewarding experience.”

Taylor describes herself as a fixer and, through Taylored Business Solutions, she negotiates the byzantine world of government projects for clients, then assists them to the finish line.

She says, “That seems to be a forte that I got into—helping contractors actually get projects completed and hopefully saving them time and money.”

n November 2024, Aaron Bartel and Kris Jensen stood before a group of 500 students at West Anchorage High School, myth-busting misbeliefs about the construction industry and highlighting all the career possibilities the field provides. The presentation was the realization of a dream three years in the making.

Associated General Contractors, or AGC, of Alaska’s Workforce Development Committee has launched its Contractor Classroom Playbook, an online guide and resource for industry stakeholders to connect the field of construction to Alaska’s schools. The Playbook is based on work by Jensen, Bartel, and others.

At a time when trades all over Alaska face a critical shortage of qualified workers, the Playbook is a practical tool for encouraging students to explore construction jobs. It’s also a resource that other AGC chapters are hoping to use as a blueprint.

“We would make headway, but it felt like one step forward, two steps back,” admits Bartel, vice president of BC Excavating. “Every time we would connect with the right people and make progress, that person would leave their job, or we’d get roadblocked, and we’d have to start over again.”

The committee also recognized that contractors wouldn’t want to waste time with untested methods.

“It’s hard to dedicate time if something’s not productive,” Bartel explains. “I already have a thousand things I’m not doing, so to walk away from the job to do something else—I’m going to need some kind of return on investment to do that.”

Bartel and the other committee members wanted to set contractors up for success inside the classroom. What was needed, the committee decided, was a comprehensive guide for making inroads at schools: making first contact with the right person, creating presentations and talking with students, and developing job-shadow and internship programs. The aim was to create a straightforward and repeatable process for contractors wanting to engage with classrooms from Anchorage to Bethel and beyond.

Don’t be intimidated by the number of pages, though. Each section in the Playbook provides three primary website resources for each topic. The appendices are supplemental and are a living document that will change over time with feedback from contractors and educators.

Kris Jensen, area manager for QAP, says the Workforce Development Committee thoroughly researched and curated the websites they chose to include.

“There’s so much information out there, it can be so daunting that you just don’t start,” he says. “You could Google a thousand sites to learn about job shadowing—so we researched websites and really found the three that we felt were most useful and engaging and helpful.”

“If you’re just up there delivering a PowerPoint, you’re going to lose them,” he advises. “If you’re unpracticed at telling your story of how you got into construction, they can see through it. You get the best reaction from students when you’re just open and honest.”

The Contractor Classroom Playbook offers tips like passing around photos or tools during a presentation so students can have a tactile experience; it encourages contractors to come up with hands-on activities that engage kids in interactive learning.

Keeping students interested can be as simple as a quick math lesson. One trick Jensen uses happens when a student inevitably asks how much money can be made in construction.

“I get them to pull up the calculator app and make them do a math problem,” he describes. “How many hours in a week is a full-time job? How many weeks for a year? What’s the wage? We multiply it out, and that helps get them into it—rather than me just telling them a number.”

Area Manager, QAP

It’s no secret that the state—like much of the nation—has experienced a deficit of workers. The hope is that talking directly to students will show them how many different opportunities the construction industry offers, sparking an interest in at least some young people to pursue construction careers in Alaska.

Around the time the AGC committee was starting to develop the Playbook, the Anchorage School District, or ASD, launched its Academies Pathway program, which uses workforce-focused curricula in the classroom. When AGC of Alaska saw that the curricula for construction wasn’t Alaska-specific, it worked with ASD to refine the career tree in the Academies program to reflect career paths in the state.

Likewise, We Build Alaska, which promotes the various career opportunities in the state’s construction industry, is another resource that goes hand-in-hand with the Contractor Classroom Playbook.

Together, Jensen says, these initiatives have the potential to “move the needle” on Alaska’s qualified workforce.

“We know it takes years and years to make something fully happen, but if we can just keep moving the needle a little bit, at least we can feel like we’re doing our part,” he says.

“Everybody was going, ‘How did you do this? What are you doing?’ There was nobody at AGC National that knew more than us about this,” says Bartel. “Which, to me—we’re just little Alaska. That was one of the turning points where I realized, wow, we’re kind of trailblazing, here.”

The digital nature of the Contractor Classroom Playbook means it can easily be shared, not only among Alaska contractors but nationally. Jensen envisions creating a “national push,” where AGC of Alaska’s Playbook is distributed to all AGC chapters.

“We’re hoping it grows and that we can exchange ideas,” he says. “Because if we’re all doing this individually, we’re siloed, and we’re not getting the message out. But if we come together nationally, we can move that needle even more.”

stablishing a good safety record takes planning, open communication, and often a lot of retooling. The Associated General Contractors, or AGC, of Alaska recognized four companies and one individual with its ConocoPhillips Excellence in Safety awards on November 7 at the AGC of Alaska Annual Convention for going beyond the basics in developing a culture of safety while on the job.

The company is using technology to change its safety management processes, adopting a cloud-based platform that uses real-time updates, such as safety reports, hazard assessments, and incident documentation, allowing for immediate review and action.

The “Blue Card” system is a hazard reporting tool that empowers employees to identify and easily report potential hazards on site, either on paper or using a mobile device. The hazards might include potential risks, unsafe conditions, or near-miss incidents. Once reported, the system allows employees to track each card from submission to resolution. It also offers space for employees to submit suggestions for improved safety practices, opening up a continuous feedback loop between workers and managers.

“It’s a new program for us. Internally we’ve been working on it for two and a half years, so to get recognized is validating,” says Alaska Crane President Brennan Walsh. Walsh is also president of STG, Inc., which he said uses the system, too.

He says having a strong safety record helps the company in several ways.

“It helps with recruiting. It shows our commitment to safety, shows our commitment to our employees and to our customers,” Walsh says. “It means something to us.”

Read more about Alaska Crane in this edition on page 18.

The extensive orientation and training program provides a foundation for a safety-conscious culture at Brice.

Brice Project Engineer Ariana Noel says she helped develop a safety program this year that the company has been using, and plans to tweak it to better fit Brice’s needs in 2025. Having a strong safety culture is important, both on the job and off, she says.

“Safety makes the job environment better; it makes people happier when they go home to their families, and it opens communication,” Noel says. “It leads to open communication in other areas and more engagement, for sure.”

“We doubled down on it, hired some additional safety professionals, and took some more time to get out to the field and inspect the jobs,” Davis Vice President Jed Shandy says.

The hard work is paying off. Davis won a safety award last year and continued its efforts to hone its safety protocol this year. Shandy noted that, in addition to building a strong internal culture of safety, Davis became early adopters of the new international standard of hard hat, handing them out to employees this year. Davis leaders, in the safety award submission, noted that safety training never stops.

“Davis is lucky enough to have many seasoned workers onsite, but like every construction company, we have also had an influx of new-generation field hands. With this mix of personalities and experiences, there have been many positives, such as new perspectives, insights, and methodologies of doing things. This unique blend of personalities on the jobsite has made us look inwards. Instead of saying, ‘This is the way we do things,’ we have been looking at our protocols and what has made our safety program award-winning and have taken note of what works in this new generation of construction and what we need to improve,” company officials noted in the submission.

Shandy says winning the award “establishes to our subcontractors and clients that we have a track record of safety, that we take it seriously.”

The company also incorporated a QR code system for near-miss or safety concern reporting that, when used, automatically sends an email to its safety consultant and to the ChemTrack Safety Committee chair, Alaska Office of Safety and Health Administration reporting staff, and the company vice president. The code is at every jobsite, home office, and shop and is included in every job folder and on every daily safety checklist that each crew member signs, ChemTrack officials said in the company’s safety award submission.

“Once a report is made, the ChemTrack Safety Committee Chair reaches out to the concerned party, provides resources as necessary, and adds the incident to the Quarterly Safety Meeting Agenda,” the submission states. ChemTrack President Carrie Jokiel says company leaders are really excited about the reporting system and has seen positive change.

ChemTrack Vice President Jenith Ziegler says keeping a good safety record also affects the company’s bottom line; having a poor safety record can affect a company’s ability to get jobs.

“So, it just helps keep everybody busy, keeping a good safety record,” Ziegler says.

“It’s nice to be rewarded for doing the right thing,” Jokiel adds.

Davis—and Parmenter—have worked steadily on different projects at Providence Alaska Medical Center. In that time, Parmenter has come up with “best practices” that have been so well-received by Providence that the hospital now requires all contractors working on the campus to adhere to them.

Parmenter says the effort was very organic, developed project by project over the span of nearly fifteen years.

“We just figured out over time what needed to happen,” he says.

Photo provided by Davis Constructors & Engineers.

“In order of the magnitude of concerns, on the low scale, a simple handprint of dust in the wrong department would be cause for concern, as that could be immune-compromised. It could be the precursor to someone’s infection,” Parmenter says. “At the same time, we have worked next to the neonatal intensive care units—and built one—and next to the intensive operating units.”

In those situations, he says, the crew had to come up with ways to reduce vibration and noise, as well as keeping dust and other effects away.

“There was no handbook when we started here. We had to learn a lot of this stuff on the fly, either through self-education or learned experience,’” he says.

Parmenter doesn’t work exclusively at Providence; as superintendent, he oversees multiple projects at the same time, Davis leaders noted in the award submission. “He manages a fleet of subcontractors and trade workers, ensuring that they understand and adhere to Davis’s safety program, meet quality standards, and keep projects on schedule.”

Despite a lengthy list of other duties, Parmenter is the primary contact for after-hours construction emergencies for Anchorage and Eagle River. He’s the first person on site for issues related to infection control, mold, lead, asbestos, and other concerns within hospital settings, as well as facility failures.

“A prime example is when Mike got a call from the Eagle River Providence’s Medical Center facility manager. They had a power outage and lost heat to the entire building. It was in the dead of winter and one of Mike’s only off days that week. Despite that, he drove from his house in Anchorage to Eagle River to see what he could do to help. He ended up figuring out how to get the heat working for the whole facility and did this all before their on-call service technician could make it out to help,” Davis leaders noted in the award submission. “Becoming the primary emergency contact for Providence was never in Mike’s ‘job description’ but rather something he naturally settled into with his dedication to the Providence team.”

Parmenter says, looking back, he’s kind of amazed at the knowledge he’s picked up. The award, he says, is validating.

“It’s come to the point of, ‘Hey, I actually did that,’” he says.

like to say we’re a civil company that backed into the marine part of it,” Toby Drake says, explaining how his business came to include government contract projects as well as moving aggregates and equipment by sea and river.

For more than forty years, Kotzebue-based Drake Construction has been expanding its operations from working on sewer and water projects into one of the leading builders of infrastructure, concrete pads, facilities, and more in one the most remote regions of Alaska.

“In rural Alaska you end up knowing how to do a little bit of everything,” Drake says. “Over the years we’ve picked up a lot of different trades.”

President, Drake Construction

“I grew up helping in the summers and learning to operate equipment and some of that at a pretty early age. I liked seeing things get completed, so I ended up sticking with it.”

After learning the trade from his father as a youth, Drake attended college in his late teens, taking classes in construction and accounting and laying the foundation for his future. Returning to Kotzebue, he joined his father’s firm for a brief period before starting his own company, Pacific West. As an Alaska Native, he was able to acquire 8(a) status for his business. The 8(a) program assists minority and disadvantaged entrepreneurs in obtaining federal contracts and helped Drake secure contracts for public projects.

After working in tandem through the 1990s, father and son merged their operations in 1999 under the name Drake Construction. Two years later, the younger Drake became president, a position he has held ever since. And when his parents retired in 2006, Drake purchased the company.

From its founding, Drake Construction has continually expanded its operations, moving rapidly into road building and maintenance, airport runways and facilities, underground sewer and water utilities, bridge rehabilitation, and more.

Project Engineer, Alaska Department of Transportation & Public Facilities Northern Region

Today, Drake says, “We not only haul gravel for ourselves, we haul aggregates and materials and equipment for other companies and other customers around the region.”

Drake Construction specializes in civil jobs over a broad swath of the region, working as far afield as Grayling, Nome, Ambler, Cape Lisburne, and even Fort Yukon, where the company provided sewer and water for the home of an elder. That’s a job Drake is particularly proud of.

Dealing with the difficult soil conditions in Northwest Alaska is a critical aspect of Drake Construction’s work. When laying foundations for any project, Drake explains, “You’re trying to make it as stable as you can.”

Neil Strandberg, project engineer at the Alaska Department of Transportation & Public Facilities, or DOT&PF, Northern Region, Western District, notes that Drake Construction is stable, both in terms of setting a good foundation and being a reliable partner in the region.

“They really set a good example of how to build projects in the northern region in difficult conditions,” Strandberg says. “Drake Construction performs a fundamental role in the Kotzebue community, keeping the community alive, maintaining infrastructure, and providing materials for earthwork projects—and they also perform heavy civil construction work. They’re great to work with and have always impressed me with how well they work together as a team.”

Drake Construction’s skills were essential in Fall 2024 when Kotzebue flooded during a brutal coastal storm October 20, 2024. An important road providing access to the city’s landfill, sewer lagoon, and a Coast Guard hangar sustained significant damage. Drake says DOT&PF reached out before the storm had even passed: “I put a small crew together, and, within a couple days, we were out there fixing it back up and getting it passable.”

Drake says the company’s future is bright, and his plan is to keep expanding the sorts of jobs it’s able to perform.

“I think there are going to be more and more as we head forward.”

t takes a different approach to work in construction in Alaska. The challenges that roads, facilities, or environmental remediation present are unlike those in any other state. Weather, geography, and a lack of basic infrastructure requires innovation, resilience, and a unique set of skills.

“Any successfully completed construction project is monumental these days in its own right. You have to deal with workforce challenges—[that’s] probably one of the biggest things we hear about; weather events—that’s getting more and more unpredictable—and obviously, schedule delays invoked by others. Those are probably the biggest things I have heard in the last couple of years that you all deal with on a daily basis,” said Lynne Seville, vice president and account executive of Parker Smith & Feek, on November 8 as she prepared to announce the winners of the Excellence in Construction awards.

t takes a different approach to work in construction in Alaska. The challenges that roads, facilities, or environmental remediation present are unlike those in any other state. Weather, geography, and a lack of basic infrastructure requires innovation, resilience, and a unique set of skills.

“Any successfully completed construction project is monumental these days in its own right. You have to deal with workforce challenges—[that’s] probably one of the biggest things we hear about; weather events—that’s getting more and more unpredictable—and obviously, schedule delays invoked by others. Those are probably the biggest things I have heard in the last couple of years that you all deal with on a daily basis,” said Lynne Seville, vice president and account executive of Parker Smith & Feek, on November 8 as she prepared to announce the winners of the Excellence in Construction awards.

ASKW-Davis, LLC, a joint venture between ASRC SKW Eskimos and Davis Constructors and Engineers, received the “Meeting the Challenge of a Job, Over $15 Million: Vertical Construction” award for building the Yukon-Kuskokwim Qavartarvik Customer Lodging Building. Alcan Electrical & Engineering won the “Excellence in Construction Award for a Specialty Contractor for a Job Over $5 Million” award for its work installing state-of-the-art electrical systems in the facility.

The project is important to the region. With limited housing available in Bethel, patients and family members from neighboring villages have few options for housing while they’re being treated. This facility, with 109 rooms, a restaurant, and other support functions, quadruples the hospital’s capacity to house patients and family members and is designed with future expansion in mind.

Kevin Clark, Davis project manager for the customer lodging building, says the project was unique in that it was built with heavy gauge metal studs and floor joists, coupled with steel brace bays and support columns, which afforded very little flexibility in terms of coordinating the work.

“ASKW-Davis decided that not only would we need to generate a 3D coordination model for the MEP (mechanical, electrical, and plumbing) systems but also every single metal stud, floor joist, and framing member. We then worked to design all of the wall and floor sections into manageable panels that could be prefabricated onsite. We constructed an onsite prefabrication building out of 40-foot containers and recycled roof trusses, complete with fabrication tables and a tracked hoist assembly. Not only did this allow us to accelerate the schedule by being able to build these sections concurrently with the pile installation, but significantly reduced safety risks from stick framing these components at height and in inclement weather,” Clark says.

Clark says winning the award “provides recognition for the efforts and sacrifices made by all parties involved to bring this project to fruition.”

“Everyone on the project team worked hard to provide the highest quality project for our client and the Western Alaska communities the facility now serves,” he says.

Chrys Fleming, president of Alcan Electrical & Engineering, says the unique challenges of Bethel required his company to design an advanced energy-efficient system and backup power, which made the project “technically innovative and impactful.” The project included energy-efficient lighting, emergency power systems, and advanced electrical panels that can withstand the harsh environmental conditions in Bethel.

Fleming says Bethel’s remoteness added logistical and climate challenges to the project, “but strong coordination with ASKW-Davis allowed us to keep everything on track.”

“Winning this award is an honor that showcases Alcan’s commitment to high-quality work in Alaska’s toughest environments. It strengthens our reputation and motivates us to continue innovating,” Fleming says.

The Shageluk project was initially intended to be a small-scale resurfacing project, but site observation showed the airport access road had recurring flooding and erosion problems. Additional study resulted in significant change orders, leading to the project cost increasing by more than 40 percent. Undocumented pit homes were discovered near the project, requiring cooperation with the community and archaeologists to identify, delineate, and protect the sites during construction. In addition, what began as a “recondition and resurface” job became much more intensive upon discovery that the previous alignment was built with organic materials, clay, silt, and sand.

“Cruz’s articulated 6-wheel drive haul trucks were barely able to operate, sinking into the flooded surface without sufficient subgrade to drive on,” Cruz officials noted in a narrative about the project, which led to a new embankment design. Then a spring flooding event kept the site submerged for several weeks at what would have been the start of construction. Cruz pivoted and used the Innoko River’s high water level to its advantage, creating new barge access points along the project route to stockpile aggregates and explosives that the contractor would need throughout the construction project. Ultimately, Cruz delivered more than twice the expected cubic yards of borrow for the project, among other changes, and left the community with three new river access points, along with a one-acre staging pad for local use and a small approach to a community garden that had become unreachable due to flooding.

The Atqasuk Airport project, located on the Meade River about sixty miles south of Utqiaģvik, posed a whole different set of challenges. There, the harsh winter had led to additional maintenance that scraped away the runway’s surface, leaving the village’s 5,000-foot runway uneven and exposing the unstable subsurface.

Lacking any suitable material sites nearby, Cruz barged aggregate and E1 gravel to Nome and then hauled it to the site using specialty 40-ton dump wagons fitted with low ground-pressure tires, traveling over winter trails. Although the company expected to need two winters to haul the roughly 35,000 tons of aggregate, equipment, materials, and fuel, Cruz was able to complete it in one with no reports of tundra damage and no need for permanent infrastructure. The company delivered gravel unusable for the project to the community landfill, where it was used to cover waste. Six local residents were hired for the project, and Cruz partnered with Atqasuk Corporation to rent and improve existing housing in the village, reducing the need for temporary facilities and expanding the village corporation’s ability to offer lodging to visitors.

“Our mission statement states: ‘The core foundation of Cruz Construction has been to honestly outwork the competition, as we humbly empower those around us and hold each other accountable.’ Excellence takes a daily grind as it requires every one of us to own our responsibilities while we help our brother and sister out,” Miller says.

Cruz is honored to be recognized by AGC, an organization the company is proud to be part of.

“Through AGC we have gained valuable relationships and friendships that help make us a more informed and a better Alaskan contractor. So, to win an award pertaining to ‘Excellence in Construction’ amongst a group of over 100 of Alaska’s best general contractors is a very high honor,” Miller says.

“It was challenging because we had to replace the CT machine, so we had to facilitate getting that out of there and getting the new one in,” said Roger Hickel Contracting President Sean Hickel. “The MRI had to be left in place, and we didn’t deenergize it until a certain time, so working around a big magnet can be fun. You can’t have any metal tools.”

Hickel says the team left the MRI machine until last so the hospital could leave it in use, then quickly got the new one in place.

The work environment—a busy hospital—posed another significant challenge.

“The most challenging aspect of this project from a management perspective was the sensitivity of working simultaneously with hospital staff and patients to limit disruptions to their daily operations during construction activities,” Roger Hickel Contracting officials wrote in the award submission. “To be as minimally invasive as possible, RHC constructed temporary walls and dust barriers around the tight working quarters and set up air hogs to scrub the dirty construction air, clean it, and discharge it outside of the critical hospital patient zones.”

Hickel says he enjoys the friendly competition the Excellence awards provide.

“We’ve been an AGC member for a long time, and I think the Excellence in Construction and safety awards are a really positive thing to get awareness of projects and the struggles we go through and all the work we’ve put in to these projects,” he says.

Cape Prince of Wales is the westernmost point of land in North America, forming the western tip of the Seward Peninsula. The Naval Field Station there was last active in 1978. The buildings on the property were abandoned in 2000. ChemTrack was hired to remediate, demolish, and remove the structures for the global engineering firm Jacobs on behalf of the US Navy. It did so, encountering several problems along the way, from a road to the site that was impassable upon arrival to a temperamental loader that slowed the process of moving materials from the barge delivery point about 10 miles from the project site. Unanticipated subsurface cables were found on the site that, left intact, posed a health hazard to the locals who use the beach regularly. The cables, World War II submarine trackers, were followed to the ocean and cut during low tide, with the ends buried. ChemTrack found asbestos in the floor of a building that was presumed to have a dirt floor, so the company sought and received approval to perform abatement without losing time on the primary project. ChemTrack discovered asbestos and lead-based paint in several of the buildings—it recorded more than 23 tons of lead-based paint or wood debris removed from the site and more than 4 tons of asbestos-containing material debris.

“I think that’s the biggest reward for everybody. The part that I love is, our people love it—the people who work for us, the site super, they request these projects, they want to go and see the difference it’s made. And it’s very satisfying at the end, to see the before and after, both for the community and for our folks as well,” she says.

In May 2022, a fire started in the old generator house for the school. It spread to the principal and teacher housing, ultimately destroying three buildings and leaving smoke residue throughout the school.

Ahtna secured the contract to clean up the extensive fire damage. Ahtna was also asked to strengthen the roof, which had been affected by heavy snowfall, and later to demolish and rebuild the gym to make it usable for the following school year.

Ahtna officials, in the award submission, said well-timed material deliveries made a big difference for the project. The school, in Kasigluk, is at the end of the 55-mile ice road from Bethel. The project site superintendent, having grown up in Bethel, knew the road would be in its best shape for a basketball tournament, so they used that timeframe to bring equipment to the school site. To stabilize a crane without damaging sensitive tundra, the superintendent tasked the crew to create a foundation for the crane by stacking heavy oak mud mats on top of insulation pads. The team later installed the mats in the children’s play area to increase their play space. Other community benefits included creating a “reclaim/reuse” area for leftover material from the demolition, and Ahtna crews offered transport to teachers to Bethel when room in company vehicles was available.