Associated General

Contractors of Alaska

Associated General

Contractors of Alaska

8005 Schoon St.

Anchorage, AK 99518

907-561-5354

Fax: 907-562-6118

www.agcak.org

ChemTrack Alaska, Inc.

Pearl-Grace Pantaleone

HDR Alaska Inc.

Alicia Amberg

Associated General Contractors of Alaska

Christine A. White

R&M Consultants, Inc.

Heather Sottosanti

Big State Mechanical, LLC

Saigen Harris

F&W Construction, Inc.

Johnathon Storter

Meridian Management, Inc.

Annie Gardner

Knik Construction Co., Inc.

Tasha Anderson

Managing Editor

Rindi White

Editor

Monica Sterchi-Lowman

Art Director

Fulvia Lowe

Art Production

James K Brown

Graphic Designer

BUSINESS STAFF

Charles Bell

VP Sales & Marketing

907-257-2909 cbell@akbizmag.com

Janis J. Plume

Senior Account Manager

907-257-2917 janis@akbizmag.com

Christine Merki

Senior Account Manager

907-257-2911 cmerki@akbizmag.com

501 W. Northern LIghts Blvd., Ste 100

Anchorage, AK 99503

The Alaska Contractor is published by Alaska Business Publishing Co. Inc. for the Associated General Contractors of Alaska. Contents of the magazine are not necessarily endorsed by AGC of Alaska or Alaska Business Publishing Co. All rights reserved. Copyright 2025 by the Associated General Contractors of Alaska. For information about articles in this edition or for permission to reproduce any portion of it, contact Alaska Business Publishing Co.

Photo provided by SECON

Design by James K Brown

8005 Schoon St.

Anchorage, AK 99518

907-561-5354

Fax: 907-562-6118

www.agcak.org

ChemTrack Alaska, Inc.

Pearl-Grace Pantaleone

HDR Alaska Inc.

Alicia Amberg

Associated General Contractors of Alaska

Christine A. White

R&M Consultants, Inc.

Heather Sottosanti

Big State Mechanical, LLC

Saigen Harris

F&W Construction, Inc.

Johnathon Storter

Meridian Management, Inc.

Annie Gardner

Knik Construction Co., Inc.

Tasha Anderson

Managing Editor

Rindi White

Editor

Monica Sterchi-Lowman

Art Director

Fulvia Lowe

Art Production

James K Brown

Graphic Designer

BUSINESS STAFF

Charles Bell

VP Sales & Marketing

907-257-2909 cbell@akbizmag.com

Janis J. Plume

Senior Account Manager

907-257-2917 janis@akbizmag.com

Christine Merki

Senior Account Manager

907-257-2911 cmerki@akbizmag.com

501 W. Northern LIghts Blvd., Ste 100

Anchorage, AK 99503

The Alaska Contractor is published by Alaska Business Publishing Co. Inc. for the Associated General Contractors of Alaska. Contents of the magazine are not necessarily endorsed by AGC of Alaska or Alaska Business Publishing Co. All rights reserved. Copyright 2025 by the Associated General Contractors of Alaska. For information about articles in this edition or for permission to reproduce any portion of it, contact Alaska Business Publishing Co.

Photo provided by SECON

Design by James K Brown

AGC MEMBER

AGC MEMBER

Qayaq Construction LLC

Qayaq Construction LLC$5,944,564

Minto Energy System Upgrades On Site Construction

STG Incorporated

STG Incorporated

$3,786,350

Bulk Fuel Utility Upgrade Project

Prism Design & Construction

$1,527,609

Hopson Middle School Windows Replacement & Upgrades

Concor LLC

$1,487,000

Boiler Replacement at FAA Housing Complex

Alaska Commercial Development Group

$1,198,028

SMCSD Teacher Housing Duplex

Kuchar Construction, LLC

Kuchar Construction, LLC

$955,000

Selawik Wind Turbine Removal

Alaska Demolition, LLC

Alaska Demolition, LLC

$268,034

Residential Water Service Line & Sewage Holding Tank Installations – Galena

Frostline Drilling and Construction LLC

Frostline Drilling and Construction LLC

$196,660

GHEMM Company, LLC

GHEMM Company, LLC$1,037,500

Noel Wien Library Parking Lot Repair

Great Northwest, Inc.

Great Northwest, Inc.

$621,814

Fairbanks Bike Lane Striping and Signing (TAP)

Exclusive Paving

Exclusive Paving

$459,939

Mowing and Planting Services at the Chena River Lakes Flood Control Project

True North Pest Control, LLC

$403,320

Utilities University Park Condensate Pipe Repair

Pro Built LLC

Pro Built LLC

$396,275

4th and State Storm Drain Extension

Exclusive Paving

Exclusive Paving

$339,913

Lathrop High School Kitchen Hood Replacement

Aaron Plumbing & Heating, Co.

Aaron Plumbing & Heating, Co.

$304,500

Herbicide Application Services at the Chena River Lakes Flood Control Project

True North Pest Control, LLC

$263,040

Great Northwest, Inc.

Great Northwest, Inc.$11,301,406

Craig Elementary and Middle School Renovations/Upgrades

MCG Constructors Inc.

MCG Constructors Inc.

$11,247,000

Aurora Harbor Rebuild – Phase IV

Western Marine Construction, Inc.

Western Marine Construction, Inc.

$7,589,700

High School/Middle School Roof Replacement and High School Entry/Office Renovation

CBC Construction, Inc.

$3,706,594

The New Pilot Point Community Center for Pilot Point Tribal Council

Yukon West Defense Technologies LLC

$3,110,230

Mendenhall Wastewater Treatment Plant Dried Biosolids Crusher System & Building Modifications

Dawson Construction, Inc.

$1,645,415

Glenn Highway MP 143-154 Resurfacing

Great Northwest, Inc.

Great Northwest, Inc.

$1,484,300

Starlite Court Reconstruction

North40 Construction Corporation

North40 Construction Corporation

$819,965

Hank Harmon Public Range Improvements

Island Contractors, Inc.

$810,908

Civic Center Green Room Renovation

Barnett Building LLC

$701,840

Cruise Dock Water and Fire Protection

Harri Plumbing and Heating, Inc.

$548,934

Wastewater Generator Replacements Phase 1

Ever Electric, Inc. dba Island Electric

Ever Electric, Inc. dba Island Electric

$298,598

USCG Air Station Sitka Housing Carpet and Installation Services

Michael Davidson

$240,000

Residential Well & Septic System Installation – Glennallen

Frostline Drilling and Construction LLC

Frostline Drilling and Construction LLC

$183,390

Schoenbar Park Parking Lot Replacement

Colaska, Inc. dba SECON

Colaska, Inc. dba SECON

$153,880

Letnikof Cove Float Removal

H.L. Tormey LLC

$143,000

Cordova Impound Lot and Transfer Facility Expansion

Cordova Powersports

$133,000

RAM Roof Replacement Drainage Improvements

B&R Fish By Products, Inc.

$125,000

Residential Septic System Installations – Valdez

Blackwell Pump Services

$109,000

ASRC Earthworks LLC

ASRC Earthworks LLC$7,303,209

Eklutna Water Treatment Facility Motor Control Center Upgrade

Sturgeon Electric Co., Inc.

Sturgeon Electric Co., Inc.

$4,829,450

Alaska Veterans & Pioneers Home Roof Replacement

Brick and Birch Homes LLC

$3,328,048

Soldotna High School Siding

Blazy Construction Inc.

Blazy Construction Inc.

$2,186,520

Gruening Middle School Boiler Room Improvements

Roger Hickel Contracting, Inc.

Roger Hickel Contracting, Inc.

$2,148,700

LHD Aircraft & Lakeshore Drive Rehabilitation

QAP

QAP

$2,073,368

ANC RON 12-14 Rehabilitation

Granite Construction Co.

Granite Construction Co.

$2,044,493

Fabrication and Supply of 2-79′ Deck Plate Girder Spans and 1-30′ Rolled Beam Span for Bridge 114.3

Jesse Co.

$2,010,036

Road Service Area 16 South Colony Annual Road Maintenance

McKenna Bros Paving Inc

$1,831,460

Baxter Family Housing – Civil Construction

Caliber Construction Alaska

Caliber Construction Alaska

$1,488,115

Chugiak Pool Renovation

Roger Hickel Contracting, Inc.

Roger Hickel Contracting, Inc.

$1,446,771

Ravenwood ES Loading Dock Awning

Eklutna Construction & Maintenance, LLC

Eklutna Construction & Maintenance, LLC

$1,301,784

Old Tyonek Creek at Airport Road and Tyonek Timber Road Fish Passage Improvements

Western Construction & Equipment

$1,021,225

Road Service Area 20 Greater Willow Annual Road Maintenance

McKenna Bros Paving Inc.

$902,884

Telephone Ave. Cable Replacement Project

Sturgeon Electric Co., Inc

Sturgeon Electric Co., Inc

$858,951

McKenna Bros Paving Inc.

$829,879

Road Service Area 29 Greater Talkeetna Annual Road Maintenance

Alaska Resource Group, LLC

$796,720

Northwood St. Maintenance Storage Facility Roof Renovation

Brad Zweifel Co., Inc.

$725,845

Road Service Area 26 Greater Butte Annual Road Maintenance

McKenna Bros Paving Inc.

$700,139

PWSC GHB Parking Lot Update

Caliber Construction Alaska

Caliber Construction Alaska

$689,365

College Gate Elementary School Pedestrian Improvements

JTA Construction, LLC

$668,128

ANC Runway 7R Concrete Joint Repairs

Brick and Birch Homes LLC

$608,789

Hope School Roof Replacement

H Construction LLC

$537,761

Construct Melanie Lane & Brian Drive Street Improvements

Dirtworks, Inc.

Dirtworks, Inc.

$484,789

2025 Apron Pavement Maint.

CR Contracting, LLC

$466,460

Deep Creek SRS Facility Rehab.

Foster Construction LLC

$450,722

Anchorage Railroad Crossing Striping Phase II

Granite Construction Co.

Granite Construction Co.

$436,950

Provide Campbell Airstrip Road Clearing – Shaded Fuel Breaks

Alaska Land Clearing Contractors LLC

$374,500

Hidden Lake Septic System Kenai NWR Alaska

AK Built Construction & Design

$362,200

Furnish Winter Aggregate to the Municipality of Anchorage, Eagle River Street Maintenance

Northern Gravel & Trucking LLC

$290,000

Road Service Area 30 Trapper Creek Annual Road Maintenance

Alaska Resource Group, LLC

$274,145

Spernak & Son LLC

$264,350

Road Service Area 19 Lazy Mountain Annual Road Maint.

Battleground LLC

$189,867

Residential Well & Septic System Installation – Healy

Pioneer Peak Industries, LLC

$181,000

Provide Vactor Cleaning Services on an “As-Required” Basis to the Municipality of Anchorage

Smithsons

$172,375

Supply & Install Fencing & Entrance Gate at Central Landfill

Mt. McKinley Fence Company of Mat-Su Valley

$169,596

Russian Jack Community Council Vertical Traffic Calming

GMG General, Inc.

GMG General, Inc.

$166,832

Kenai River Ctr. Roof Replacement

Building Specialties Inc

$165,975

Egan Ctr. Lighting Control Upgrades

Premier Electric LLC

$162,000

Provide Street Maintenance Structures for Multiple Projects to the Municipality of Anchorage, Eagle River Street Maintenance

D&S Concrete Inc

$149,547

Furnish Signage Materials to the Municipality of Anchorage, Public Works Department

Sign Solutions USA

$147,133

Nikiski North Star Elementary Windows Replacement

R Squared Contracting and Engineering, LLC

$133,340

North Peninsula Recreation Service Area Pool Flooring Renovation/Remodel

R Squared Contracting and Engineering, LLC

$126,918

Provide Annual Generator Testing and Maintenance Services

Pacific Power Group

$101,955

Gym Floor Refinishing Services

AK Premier Finishing and Supply

$100,878

MESSAGE

ssociated General Contractors, or AGC, of Alaska is built on the strength of its members—contractors, suppliers, and professionals who bring their insight, experience, and passion to the table. One of the most impactful ways members can shape the future of our industry and association is through active participation on AGC committees. Now more than ever, we are looking for new voices, fresh perspectives, and committed individuals to help lead the charge.

We understand that many members are busy running companies, managing teams, and meeting deadlines. But that’s exactly why your voice matters. You see the challenges firsthand, and you likely have ideas and insights that could benefit others in the industry. Joining a committee gives you a platform to share those ideas and help shape AGC’s work on behalf of all members.

You don’t need decades of experience or a long history with AGC to make a difference. In fact, some of the most valuable contributions come from those who bring a fresh lens and a willingness to ask different questions. Whether you’re a seasoned project manager, a new estimator, or running your own small business, there’s a seat at the table for you.

- The Construction Leadership Committee, or CLC, is ideal for emerging professionals looking to build their leadership skills, grow their networks, and take on greater roles within AGC and the industry at large. The CLC hosts events, supports professional development initiatives, and helps ensure the next generation of leaders has the tools and support they need to succeed.

- Like reading this magazine? Then consider joining AGC’s Magazine Editorial Board. The Editorial Board oversees AGC’s publication of The Alaska Contractor magazine. This committee works to ensure our communications reflect the work, voice, and concerns of our members. Help us highlight the work AGC members do statewide and ensure our messaging remains clear, relevant, and compelling.

Whether you’re interested in shaping policy positions, supporting workforce development initiatives, or growing AGC’s membership, there’s a committee for you.

If you’ve ever asked, “Why doesn’t AGC do X?” or “Wouldn’t it be great if we had Y?” being on a committee is your chance to be part of the solution. Your input helps shape the resources, events, and advocacy that AGC offers to all members.

s Alaska’s construction season ramps up, it’s time to refocus on the core priorities that shape our industry. From reinforcing our unwavering commitment to workforce safety, highlighting exciting opportunities, and recapping our recent advocacy efforts in Washington, D.C., it’s safe to say we’ve been busy. But as everyone in the industry knows, “busy is good” and the work we do together paves the way for a safer, stronger, and more prosperous future for Alaska’s construction community.

I can’t emphasize enough how important it is to respect these spaces and people working in them. Be safe, slow down, pay attention, and follow the rules. We all share responsibility in ensuring that every worker and every driver gets home safely at the end of the day. As we move into this busy season, I encourage you to promote a safety-first culture on every job site and every road you travel. Lastly, share this message with your family and friends—doing so could save a life.

During Agency Day, we received promising updates on projects poised to provide Alaska’s construction industry with a massive shot in the arm. First, progress made on the Alaska Industrial Development and Export Authority’s Ambler Road project is noteworthy. We learned that multiple Construction Manager/General Contractor (CM/GC) contracts for this significant infrastructure project are expected to be out for bid this year. The 211-mile road will provide access to almost 600,000 acres of state mining claims. Since 2020, more than $80 million has been invested in Alaska for this project. This project is estimated to create 2,777 direct jobs with $286 million in wages annually during mine construction and 360 direct jobs annually during road construction.

Additionally, the discussion around the Alaska LNG/Glenfarne natural gas project incited excitement amongst attendees. This effort to monetize Alaska’s vast North Slope gas resources while providing Alaskans with affordable energy would create countless opportunities for AGC members. The current plan is to build an 807-mile pipeline from the North Slope to Southcentral Alaska, as well as facilities to process the gas into liquid for overseas shipment.

The project is planned in two main phases: Phase 1 focuses on building the pipeline itself, estimated to cost $10.8 billion. Phase 2 involves building the gas treatment and LNG export facilities at an estimated cost of $33 billion. Glenfarne will serve as a major partner, taking on a 75 percent share and financial responsibility. If it moves forward, Alaska is likely to experience a building boom similar to when the Trans Alaska Pipeline System was constructed decades ago. To say we are keeping a close eye on this exciting opportunity is an understatement.

Discussions during “Alaska on the Hill” cover topics central to Alaska’s construction industry. These include federal funding for infrastructure projects, responsible resource development, environmental regulations, and policies that support economic growth. Supporting “Alaska on the Hill” allows us to join forces with our trade organization partners to advocate for federal decisions that benefit all industries, including construction. We make quite the splash when we all show up together with the same messages.

PO Box 73576, Fairbanks, AK 99707

907-385-2211

chris.bsr@outlook.com

www.bsrinfo.com

3035 C St., Anchorage, AK 99503

907-222-5200

tcline@haskellcorp.com

www.haskellcorp.com

Patrick McAnally, General Manager

3900 C St., Anchorage, AK 99503

907-339-5900

pmcanally@asrcconstruction.com

www.asrcconstruction.com

Meg Nordale, President

Harold Baysinger, General Manager

3861 Schacht St., Fairbanks, AK 99701

907-452-5191

info@ghemmsolutions.com

6200 Blackberry St., Anchorage, AK 99502

907-602-9636

infinity.electric.ak@gmail.com

PO Box 230405, Anchorage, AK 99523

907-317-6488

ssaloka@salokainc.com

www.salokainc.com

3340 Arctic Blvd., Ste. 202, Anchorage, AK 99503

907-600-1751

clyde@49thfreight.com

www.49thfreight.com

3852 N. Clark-Wolverine Rd., Palmer, AK 99645

907-521-4676

gbrewer@alaskaearthworks.com

Arnold Akers, Manager

PO Box 2408, Palmer, AK 99645

907-745-4049

office@alaskafencemanufacturing.com

8907 Yandukin Dr., Juneau, AK 99801

907-523-3597

erica@flyalaskaseaplanes.com

www.flyalaskaseaplanes.com

200 E. 100th Ave., Anchorage, AK 99515

907-375-1280

aesping@builderschoice.us.com

www.asrcconstruction.com

325 Chestnut St., Ste. 700, Philadelphia, PA 19106

215-969-1000

kayla.hall@cbiz.com

www.compudata.com

Haley Gamache, Training and Operations Manager

2217 E. Tudor Rd., Ste. 16, Anchorage, AK 99507

907-301-5155

info@frontiersafetyandsupply.com

www.frontiersafetyandsupply.com

6001 E. Chinook Ave., 1D, Wasilla, AK 99654

360-209-2156

henry@hprecruitment.com

www.hprecruitment.com

3821 Amber Bay Loop, Anchorage, AK 99515

907-290-4339

Alaskafpe@gmail.com

PO Box 111207, Anchorage, AK 99511

907-677-2601

jstorter@meridianak.com

335 Athena Dr., Athens, GA 30601

832-566-1416

cody.huff@skaps.com

www.skaps.com

Amber Schoff, Account Executive

5333 Fairbanks St., Ste. B, Anchorage, AK 99518

907-563-2242

Daniel.Hart@siemens.com

Amber.Schoff@siemens.com

www.siemens.com

11400 SE 8th St., Ste. 380

Bellevue, WA 98004

206-326-4284

Tbelling@travelers.com

www.travelers.com

3875 Geist Rd., Ste. E#432

Fairbanks, AK 82801

907-590-9519

e.denty@ua-pm.com

www.ua-pm.com

Photo provided by AGC of Alaska

ummer is in full swing and, as Alaskans, we know what that means: construction. For the casual driver, that might mean a slight delay on the way to or from work, or perhaps a longer delay on the way to a camping or fishing trip. But to construction industry workers, summer means trying to do a job while hundreds—or perhaps thousands—of people stream through their workplace. Most people are polite, respectful, and focused on their own goals. Some might be distracted—by technology, by traveling companions, by the surrounding scenery, by preoccupying thoughts, or myriad other reasons. Speed and distracted driving are the top two causes of accidents in work zones.

Notably, it’s not highway workers who are most often injured or killed in work zone accidents—it’s drivers and passengers in personal vehicles. In 2022, 742 drivers and their passengers died in work zones, according to the National Highway Transportation Safety Administration. The National Work Zone Safety Clearinghouse reports that, in 2022, the most recent year for which data is available, there were 96,000 estimated total work zone crashes, 891 total work zone fatalities and 37,000 work zone injuries.

Although the data is sobering, there is reason for hope: the Bureau of Labor Statistics Census of Fatal Occupational Injuries reported that fatal highway worker injury numbers have decreased from 124 in 2018 to 94 in 2022.

The week kicked off with Work Zone Safety Training Day, which emphasized the importance of laying the groundwork for safety through training. Companies were encouraged to pause for safety demonstrations or discussions about safety practices throughout the day. One safety focus by organizers this year was struck-by injuries, which were the second leading cause of death among construction workers between 2011 and 2021 and the leading cause of non-fatal injuries in the construction industry between 2011 and 2020, according to the Center for Construction Research and Training. Falls to lower levels were the leading cause of death during that timeframe.

On April 22, Alaska Department of Transportation and Public Facilities, or DOT&PF, Commissioner Ryan Anderson shared a message for drivers: remain vigilant.

“Work Zone Awareness Week is a reminder that behind every orange sign are skilled DOT&PF staff and contractors working together to improve safety and reliability for all Alaskans. We ask drivers to stay alert, slow down, and help protect the people building and maintaining the roads we all rely on,” Anderson said.

Construction industry workers across the nation marked Go Orange Day, April 23, by wearing orange to show their support of work zone safety. A social media storm in which construction industry workers were invited to share messages regarding work zone safety was held April 24, and NWZAW wrapped up on April 25 with a moment of silence in tribute to people who died as a result of a work zone accident.

- Avoid distractions. Focus on driving safely through the work zone and avoid distractions such as phones.

- Reduce speed. Obey posted speed limits through work zones.

- Be aware of workers. Work areas are often close to travel lanes, so be vigilant and slow down when workers are present.

- Watch for pedestrians and bicyclists. Work zones often restrict where nonmotorized road users can travel and may make their travel more hazardous.

- Give commercial motor vehicles space. Narrow lanes, unexpected lane shifts, and longer braking distances are challenges for large vehicles. Allow extra space for all large vehicles to safely navigate work zones.

- Reroute. Follow signed detours or view traveler information sources that display active work zones and select alternate routes.

or Lucas Dubie, workplace safety transcends personal and business interests.

“I heard it when I was in school,” he says. “Someone said safety is not proprietary.”

Dubie is bringing that outlook to the Associated General Contractors, or AGC, of Alaska Safety Committee, to which he was recently named co-chair. When he was offered the position, he says, “I was super, super excited to do it.”

Dubie, recently named the Regional Safety Manager at Granite Construction, has been focused on the wellbeing of fellow workers throughout his professional life.

Born and raised in Alaska, Dubie attended UAA, where he earned his bachelor’s degree in occupational safety and health. He went to work for Granite after graduating in 2018, initially working in quality control. “And then I switched over to safety in 2020 as an intern,” he says.

From there his career moved quickly. He became a specialist and then a job site safety manager before moving into the regional seat.

“It’s been a kind of a quick, crazy five years,” he says, “but I really enjoyed it.”

“I sat in to see how it was running,” Dubie recalls. “I really enjoyed it. I thought it was a good group.”

Impressed by the mix of safety experts and people in the field he met on the committee, Dubie began accompanying Rodriguez to meetings, trainings, and safety fairs.

When Rodriguez announced that he was leaving the state, the committee asked Dubie to fill the seat. He says he initially felt that others who had served longer on the committee would be better qualified, but members told him they wanted someone who could bring in a fresh perspective.

Rodriguez, who moved into the Regional Safety Manager position for Granite’s Vancouver, Washington-based Columbia River region, says Dubie is perfect for the co-chair seat.

“Lucas is an extremely passionate and driven safety professional with strong leadership and communication skills,” Rodriguez says. “He is a lifelong Alaskan who has dedicated his career to advancing worker safety and wellness in the construction industry. It has been an absolute privilege for me to work alongside Lucas for nearly six years, and I am excited to see the great things the AGC Safety Committee achieves under his leadership alongside fellow co-chair Dora Hughes.”

Dubie says one area that he feels is important for the safety committee to address is mental health. It’s not just for on-the-job safety that he wants to expand the committee’s focus on this topic but also the humanitarian wish to reach those needing aid by removing the stigmas surrounding this aspect of health and getting them the help they need.

“We may not be experts in the field,” he says about what the committee’s role should be when workers need mental health assistance, “but we can at least start getting resources together, get the conversation going, and then actually pull in people that know what they’re talking about and help us out.”

Dubie says the committee holds safety fairs tailored towards children, hosts workshops and lunch discussions covering critical safety issues, and is upgrading its safety data base to make it more thorough and accessible to all AGC members.

“If they have a question or they need some regulatory assistance,” he says, they can “look at this database and pull out all kinds of different safety information.”

For Dubie, safety is important for both employee welfare and the betterment of AGC member companies. Forewarned is forearmed, as the saying goes.

“If we can help give people what they need beforehand,” he says, “then they’ll be successful.”

om DePeter, president and CEO of Onyx Drilling, LLC, got his first summer job as a drill helper when he was a 16-year-old high-school student in Fairbanks. Thirty-two years later, DePeter jokes it’s almost like he never left.

“I’d go to school during the winter and work on the drill rig in the summer, then it just continued,” he says. “My summer job has never ended.”

Today, DePeter has transformed that never-ending summer job into one of Alaska’s leading drilling contractors. And he’s built it on the strength of his reputation, a willingness to tackle the most challenging jobs, and a baseline standard of perfection.

“I had a big plan, but nobody wanted to give some kid from Fairbanks 2 million bucks,” he says with a chuckle.

When the opportunity to achieve that lifelong dream materialized in 2012, DePeter says he jumped on it. He kept Onyx Drilling true to his roots, focusing on mine-related drilling and gold exploration, he says. The transition to geotechnical drilling and construction a few years later “started some serious growth,” he adds.

“We bought the most modern foundation equipment and then landed a couple of good-sized projects in Prudhoe Bay, and it’s been off and running since then,” DePeter says. “We have the most modern sonic and foundation drill rigs in the state. There’s pretty much no drilling project that we can’t do, I would say.”

Onyx Drilling is based in Fairbanks but works statewide, whether at sea level or mountaintop.

Vice President, PND Engineers

“We do a lot of projects that are very remote, challenging projects,” DePeter adds. “That’s kind of what has set us apart.”

Torsten Mayrberger, an engineer and vice president of Associated General Contractors, or AGC, of Alaska member company PND Engineers, has worked on numerous projects with Onyx Drilling. He says the company is his first choice.

“If it’s anything to do with drilling holes in the ground or installing piles, they’re absolutely my go-to,” he says. “After so many years, I can’t imagine doing some of the more out-of-bounds stuff without Tom.”

Mayrberger cites a cone penetration testing, or CPT, sampling project the duo conducted from a sheet of floating ice in April 2024 as one of their more “out there” projects.

“It was something new that we did here in Alaska,” he says. “We both like a challenge and are kind of allergic to bread-and-butter jobs. The crazier the project seems, the more interesting it becomes to both of us.”

“We’re small and very diverse, so we kind of pick and choose our projects,” DePeter says. “There are quite a few that we pass on. If I had my way, I’d do every job that came across the desk, but that’s not the case.”

What makes Onyx Drilling’s full workload even more impressive is that it has zero social media presence and is only just now creating a website—“We’re definitely behind the times on all of that,” DePeter says—which means the company relies heavily on word-of-mouth referrals and networking. That’s what makes membership in the AGC of Alaska worth its weight in gold.

“I think the most beneficial thing of being involved in the AGC is just their networking system and getting our name out,” he says. “Going down to Anchorage annually and chatting with all the folks that go there I’d say is the most beneficial thing for us.”

That, and giving clients nothing but positives to share about their work.

“I’m sure everybody strives to give their best, but I think that’s our thing,” Eddy says. “We want to get in and get out and make it perfect every time.”

“We definitely strive for perfection with every job we do,” DePeter agrees. “That’s kind of our motto: ‘Perfect is adequate.’”

ore than twenty Associated General Contractors, or AGC, of Alaska members and staff made their voices heard in Juneau during the Legislative Fly-In, held February 25 and 26. It’s an annual event that helps AGC educate legislators about the importance of the construction industry to Alaska and discuss issues of concern with state staff and department heads. AGC of Alaska joined with the Alaska Miners Association and Alaska Trucking Association to host a reception at the Baranof Hotel February 25 that was well-attended by members of the hosting organizations and legislators.

Through the two-day fly-in, members met with nearly thirty state legislators and commissioners. Department of Labor Commissioner Cathy Muñoz spoke with AGC members at a luncheon, updating them on industry-related topics her department was working on. AGC members also participated in a four-hour meeting with Alaska Department of Transportation and Public Facilities staff, along with follow-up meetings with department officials throughout the week.

he 34th Alaska State Legislature adjourned its 2025 session a day early, gaveling out on May 20. The House and Senate garnered enough votes to override Governor Mike Dunleavy’s veto of the education funding bill, House Bill, or HB, 57, that includes some policy measures and an approximate $700 increase to the Base Student Allocation. At the time of this article, it was yet to be seen whether the Governor would line-item veto the associated appropriation.

While lawmakers met their constitutional duty to pass a balanced budget, they failed to secure the three-quarters majority vote needed to fund the fiscal year 2025, or FY25, supplemental budget of $193 million using the Constitutional Budget Reserve, or CBR, one of the state’s main savings accounts.

Without the ability to use the CBR, funding FY25 expenses defaults to contingency language added by the House and Senate Conference Committee to use up to $100 million from the unrestricted balance of the Alaska Industrial Development and Export Authority, or AIDEA. Any remaining deficit above $100 million would come from the Higher Education Investment Fund, or HEIF—not an ideal fix, as this could have a significant negative impact on AIDEA’s bonding rate.

The capital budget also remained austere, with the notable absence of district priority projects. But it did include funds for deferred maintenance and statewide emergency response. Some highlights:

- $1,000 PFD

- $700 increase to BSA

- Increases to childcare grants and behavioral health support

- Additional funding for Village Public Safety Officers and funding of State Trooper overtime hours

- $36 million in deferred maintenance for schools, university facilities, and statewide emergency repairs

- Alaska Marine Highway vessel maintenance, using $26 million in fare revenue

- Dalton Highway, or Haul Road, maintenance

- Port electrification for cruise terminals

Key legislative efforts this session included Associated General Contractors, or AGC, of Alaska’s invitation to testify before the Senate Transportation Committee on the importance of a robust, timely, and accurate Statewide Transportation Improvement Plan, or STIP. AGC Executive Director Alicia Amberg, along with industry representatives, shared concerns regarding the lack of available projects for this summer’s construction season. Additionally, AGC, in partnership with the American Council of Engineering of Alaska, provided the state Department of Transportation & Public Facilities, or DOT&PF, and legislators with an industry white paper defining key metrics for a successful DOT&PF program, year over year.

AGC engaged in advocacy efforts on numerous bills, including HB 161, pertaining to paid sick leave exemption, which would exempt employers with fewer than fifty staff members from the state’s new sick-leave requirements, implemented via Ballot Measure 1, which passed in 2024.

AGC supported HB 148/Senate Bill 132, pertaining to controlled insurance programs, and provisions in HB 133, supporting prompt payment to prime contractors. We voiced concern over HB Bill 186, which requires a percentage of workers on state projects to be in a registered apprenticeship program, and were successful in our efforts to encourage legislators to not approve this bill as written.

AGC’s Legislative Affairs Committee, or LAC, held weekly meetings where bills were continually monitored and reviewed to determine support, opposition, or neutrality. AGC voiced support for bills that would have positively enhanced our industry and discouraged movement or provided alternative solutions on several bills that could have negatively impacted our industry. The LAC laid the groundwork to continue our work on these bills in the next session.

LAC members organized a well-attended fly-in event to the state capitol in February, with more than twenty participants—the most to date! This year’s fly-in looked a little different than in past years, with the primary focus being on advocating for a robust DOT&PF program. AGC members met with key legislators and policymakers to voice concerns contractors faced as they geared up for a less-than-robust summer construction season. AGC’s concerns resonated throughout the Legislature; we will continue to dialogue with elected officials and DOT&PF staff to discuss ways to ensure DOT&PF’s annual construction program is sustainable for industry given the state and federal budget climates.

The fly-in event, along with the continued work of the LAC, plays a crucial role in advancing industry priorities, shaping policy outcomes, and championing a supportive business climate for the construction industry.

Eye Tooth Tavern & Eatery

Contractor

Cadence General

Jon James

Project Manager

Kendall Wilson

Cadence General

AGC Member Since 12/16/2021

hen embarking on industrial jobs in remote regions of Alaska, companies face a multitude of challenges: preplanning, engineering, logistics, operations, aviation safety, medical care, and weather forecasting, for example. That’s where Fairweather LLC comes in, with its large staff of professionals to supply expertise.

“It depends on what the client needs,” Fairweather President and General Manager Rick Fox says, summarizing the company’s range of services.

For nearly half a century, Fairweather has been handling details that allow businesses to bring their visions to fruition.

“We fill in all the gaps where they need help,” Fox explains. “We’re supporting our clients to reach their goals.”

Founded in 1976 by Sherron Peary, a friend of Fox’s since high school, the company began by providing aviation-related weather forecasting at remote drilling locations. From there, Fairweather quickly expanded into other arenas, including runway certifications, coordinating materials deliveries, engineering, and—crucially—supplying rigs and other worksites with trained medical professionals able to provide routine and emergency care in places where clinics and hospitals might be hours away.

President and General Manager,

Fairweather LLC

A Fairweather employee on site in Black Rock City—the temporary city that springs up around Nevada’s Burning Man celebration—installing a temporary remote runway, complete with a Fairweather windsock.

During the ‘90s, Fox relocated to Louisiana, but when Shell purchased some leases in Alaska in 2005, “they asked me to come back up, open the office, and get started.” Five years later, Fox retired and was asked to join Fairweather. “Eventually I became a half owner of the company.”

Much of Fairweather’s work continues to revolve around drilling, he says. “We typically do operational forecasting, like sea and ice conditions for offshore, and weather for onshore.

“Aviation support is another big piece,” Fox adds, explaining that Fairweather provides “forecasts for planes before they try to approach an airport.”

They do a lot more as well, he continues. “We support the industry in every way. Everything from project management to drilling engineering, completion engineering, logistics, and civil engineering. Most of our teams are set up to do projects or drilling programs.”

Smaller companies that can’t afford the resources to do the services-related jobs themselves comprise a sizable portion of Fairweather’s client base, Fox notes. “This is a big deal and they need a lot of help. We want to get it done right for them.”

One of those companies is Alaska-owned Furie Operating Alaska. “We’ve got people involved with [Furie] in different areas, and we’re glad for their success,” Fox says.

Furie president and CEO John Hendrix values his company’s partnership with Fairweather, calling it “a local company that has survived and thrived since 1976. They have great people with great depth in the sciences and engineering that I would highly recommend. Fairweather is currently managing and supporting our offshore Cook Inlet drilling program. The project is currently on schedule to deliver much needed natural gas for Alaskans in July.”

In Alaska’s famously unpredictable economy, Fox says the key to Fairweather’s longevity has been its ability to quickly adapt to new circumstances. “We look at what work is out there and we figure out how we can adjust our plan to take on what the clients need. We’ve seen times when exploration was very slow and other times when they were stacked on top of each other and we could hardly get all the work done.”

The pandemic brought entirely new and unprecedented challenges as worksites simply shut down. But thanks to its medical staff and experience, Fairweather won a federal contract running vaccination clinics across the state. “We did a lot of things to support our community and keep our people employed during COVID,” Fox says.

Doyon, Limited recently acquired 90 percent of Fairweather, which currently has about 360 employees.

“They’re a great Alaska company to work with, they bring strengths to the table that we didn’t have before,” Fox says of Doyon, adding that the future looks rosy for Fairweather and for Alaska. “It’s a very exciting time. I expect over the next couple of years, we’ll see more and more activity.”

n the heart of Prince William Sound, the remote village of Chenega stands out as a place known for its stunning beauty, enduring resilience, and persistent challenges. Accessible only by air or water, this isolated community dreamed of reaching a major milestone in its efforts to accommodate the people who play a vital role in its sustainability. With the completion of the Chenega Multipurpose Housing Facility, the community’s vision is now a reality.

Led by F&W Construction Company, Inc. and guided closely by Chenega Regional Development Group, LLC, the $6 million design-build project is a direct response to the community’s severe housing shortages that came into focus during the COVID-19 pandemic. But its purpose will go well beyond pandemic recovery.

The facility will serve as a home away from home for visiting teachers, healthcare professionals, emergency responders, and construction workers who are essential to the region’s continued growth.

“Chenega has long faced a shortage of housing to accommodate essential personnel who come to support the community,” says Doug Lipinski, project manager for Chenega Regional Development Group. “This project marks the most significant expansion of housing in Chenega since the community resettled on Evans Island in 1984, following the devastating impact of the 1964 Good Friday earthquake and tsunami on the original village site on Chenega Island.”

With walls up and windows installed, the Chenega Multipurpose Housing Facility nears completion in its remote coastal setting.

Urgent and Lasting Needs

The new facility provides the infrastructure to support visiting professionals and frees up housing within the village, allowing for more long-term residential growth, says Lipinski. It represents a turning point in Chenega’s post-resettlement development and provides critical flexibility for hosting educational, medical, and infrastructure teams.

The building is designed with flexibility and functionality in mind, Lipinski says, featuring six separate living units and a shared common area that can be used as a meeting or gathering space. The layout includes two efficiency units, two two-bedroom units, and two three-bedroom units.

Each space is equipped with a full kitchen, providing comfort and independence for short- and long-term guests. In total, the facility can house up to twelve people.

Chenega Regional Development Group selected the site for the facility to capitalize on the stunning views of Crab Bay, located in southwestern Prince William Sound—west of long, narrow Montague Island and east of Seward. This intentional design decision not only enhances the quality of life for those staying in the units but also highlights the natural beauty that defines Chenega, says Lipinski.

Though the building was not yet ready for occupancy in early May, the community already began to respond positively.

“People like the layout of the units and the views,” says Lipinski, noting that initial walkthroughs have generated enthusiasm about the thoughtful design and comfort of the facility, which opened in June.

“We had to ensure constant delivery of food and materials to the site—something that’s incredibly difficult in winter,” says Saigen Harris, project manager for F&W Construction and Associated General Contractors, or AGC, of Alaska president. “There were two different periods where we couldn’t get materials or food for over two weeks. But because of our planning and forecasting, there were no safety issues or schedule impacts.”

Anchorage-based F&W has more than six decades of experience delivering infrastructure in Alaska’s most challenging environments. A third-generation, family-owned firm, F&W has built its reputation on integrity, safety, and innovation. Its teams are skilled in a variety of construction disciplines, from structural steel and modular construction to timber framing and pre-engineered buildings.

The company has a deep understanding of rural Alaska’s seasonal and logistical challenges, says Harris. F&W’s crews are highly experienced in transporting materials by barge, plane, and helicopter to isolated job sites. The team’s logistical planning and field expertise helped ensure this project was equipped with the right people, tools, and materials to succeed safely and efficiently.

Project Manager, F&W Construction Company, Inc.

A fully equipped kitchen in one of the units of the new Chenega Multipurpose Housing Facility is ready for use.

More than a Building

Local input played a crucial role in shaping the project. Village-based Chenega staff shared institutional knowledge that informed key decisions—from landing sites for materials to site preparations for winter.

“Their involvement helped ensure that this project was grounded in local realities and responsive to the village’s needs,” says Lipinski.

A collaborative network of highly skilled subcontractors and consultants ensured the success of the Chenega Multipurpose Housing Facility. AK Underground’s civil work enabled rapid mobilization, expediting the construction schedule. Samson Electric and Slayden Plumbing & Heating Inc. also played major roles, providing in-depth design reviews that prevented change orders later in the process. AGC member companies working on the project included project architect KPB Architects; Malone Construction LLC, which performed concrete placement and finishing; and roof installer Rain Proof Roofing.

Their early participation in the design phase allowed F&W to spot potential issues long before they impacted the job site, says Harris. That kind of foresight is what made the difference in sticking to the schedule and avoiding costly changes.

While the Chenega Multipurpose Housing Facility may be a single structure, its impacts are broad and deeply felt. Overall, it strengthens the community’s infrastructure, honors local knowledge, and provides a much-needed lifeline to those who come to support the village.

And as Chenega continues to grow and rebuild in the wake of its relocation, Lipinski says this project represents progress and possibility, proving that, even in the most remote corners of Alaska, development rooted in responsiveness and respect can be successful.

etting the year started in style, Associated General Contractors, or AGC, of Alaska members met Thursday, May 1, at the Westmark Hotel in Fairbanks for a Spring Kick-Off party ahead of an all-day Friday agenda filled with presentations from the Alaska Department of Transportation & Public Facilities, Alaska Gasline Development Corporation, the Alaska Industrial Development and Export Authority, the Alaska Railroad, UAF, Fairbanks-North Star Borough, and City of Fairbanks. Around 150 people attended the Agency Day talks, including the highly-attended lunch presentation by Davis, Wright, Tremaine LLP discussing how to avoid pitfalls when implementing Ballot Measure 1, pertaining to sick leave.

The Thursday reception included a meet-and-greet for prime contractors and Interior-based disadvantaged business enterprises, or DBEs. Some state contracts, particularly for projects within the Alaska Department of Transportation and Public Facilities, have requirements regarding hiring DBE-certified companies; the meet-and-greet provided an opportunity for networking.

AGC of Alaska would like to thank the Spring Kick-Off and Agency Day sponsors for making the event a success:

- STG Pacific, LLC

- Yukon Equipment, Inc.

- Brice Pacific, LLC

- Great Northwest Inc.

- Brice, Inc.

- Equipment Source, Inc.

- Loken Construction LLC

- Meridian Management Inc.

- Shannon & Wilson, Inc.

- TOTE Maritime Alaska, Inc.

- Alaska Powercom Supply

- Denali Industrial Supply

- F & W Construction Co., Inc.

- Granite Construction Company

- Hale & Associates, Inc.

- Loken Crane, Rigging & Transport, LLC

- North Star Equipment Services

- Olson Creek, LLC

- PFK Enterprises, Inc.

- TDL Staffing

Victaulic Company

ictaulic has experienced every kind of economic cycle, market shift, and industry trend imaginable since it created its first pipe coupling in 1919. Its founder, Ernest Tribe, built the concept of resilience into the company name, a combination of the words “victory” and “hydraulic.” After 106 years in the business, Victaulic continues to innovate the pipe-joining technology used in structures worldwide.

Alaska Territory Manager Derek Bradish says Victaulic completed several water treatment projects in Alaska in 2024. The company outfitted plants in Wrangell and Bethel with Victaulic coupling systems and provided mechanical services to a at Joint Base Elmendorf-Richardson. He says it was a particularly busy year, filled with many similar projects—which is sometimes challenging, as he is the only Victaulic manufacturing sales representative in the state.

“When you’re the only one here, time management is the biggest challenge,” says Bradish. “I wear a lot of different hats and work with people in many different industries.”

Bradish says his position also requires him to become an expert in multiple industries. For instance, the products and systems needed for a wastewater plant are different than what is necessary for an oil and gas power plant or a mine. The only way to fully assist these different industries is by becoming well-versed in their specific needs.

Since its official inception in 1925, Victaulic has created pipe-joining solutions to meet these needs. Its initial grooved, malleable iron fittings quickly became the standard worldwide for oil, gas, water, sewage, and air pipelines, as well as water and air lines for mines. Later, Victaulic adapted its products to plumbing, heating, and air-conditioning systems. As the construction industry continued to boom, Victaulic increased its focus on product development, which led to the innovation of valves, flange adaptors, and mechanical tees.

Innovation in products and services is nonstop, says Bradish. Over the past two years, he says, Victaulic has developed new valves and gaskets better suited for specific types of media in the pipe. For instance, the company offers a new gasket that can handle the various chemicals used to treat and disinfect water. Bradish says that many states use a different combination of chemicals to make water safe for human consumption, so it made sense to develop a gasket that could withstand multiple processes.

“In this day and age, we are constantly innovating materials and technology,” says Bradish. “Our new couplings and gaskets are better than the last ones, and we didn’t come out with those all that long ago.”

Last year, Victaulic worked with Mantech Mechanical to outfit the water treatment plant in Wrangell with a new coupling system. Victaulic completed several other similar coupling projects statewide in 2024.

Joint Efforts and Connections

“It’s a long process,” says Bradish. “These jobs have a lifespan of two or three years, and you start working now, so they come to fruition four or five years down the road.”

Victaulic has played a vital role in numerous projects statewide. Noah Velasquez, chief operations officer for Inlet Mechanical, says the recently renovated Bethel Water Treatment Plant features various types of plastic, copper, and steel Victaulic systems. Inlet Mechanical first worked with Victaulic about five years ago, when their products were listed in the job specification. Since then, the two companies have built a strong relationship.

“They are very helpful with making sure they can provide you with what you need,” says Velasquez. “They have the knowledge and skills to install their products and offer services that meet the scope of the project.”

Victaulic has been an Associated General Contractors, or AGC, of Alaska member since May 2015. Bradish says networking is the main AGC benefit his company appreciates. There are so many great people in Alaska, and the ability to connect with contractors and develop genuine friendships and solid working relationships is valuable, he says. AGC offers many fun events that allow members to get to know each other and celebrate hard work, he adds.

oint Base Elmendorf-Richardson, or JBER, is slated for another round of extensive military construction in 2025. As crews continue work on JBER’s north-south 16/34 runway extension, the US Army Corps of Engineers–Alaska District, or USACE, is close to selecting a contractor for a new state-of-the-art Joint Integrated Test and Training Center, or JITTC. These projects, and several others statewide, are part of a larger national defense strategy to increase operational readiness, safety, and security.

Alaska’s proximity to both Asia and the Pacific makes it an ideal launching point for homeland protection. Alaska is considered a critical component to the nation’s ballistic missile defense system, and military bases here will serve an expanding role of protection as companies explore arctic shipping lanes that, due to decreasing sea ice, are increasingly open for travel.

To prepare forces for the new challenges, the US Department of Defense, or DOD, is investing up to $500 million to develop a facility at JBER that will increase the responsiveness of agile combat warfighters and support teams.

The JITTC construction project includes a 150,000-square-foot technologically advanced facility that will house the joint-simulated-environment, or JSE, training platform; simulator rooms; briefing rooms; mission operations centers; a central server room; an auditorium; administrative space; a security office; break rooms; and storage. Crews will also build supporting infrastructure for the facility, such as a utility yard for chiller equipment, standby generator enclosures, fuel tank areas, and a 15 MVA substation. The project will include additional site improvements such as earthwork, landscaping, exterior lighting, parking, sidewalks, and roads.

JITTC will be built to withstand cold weather conditions, with a reinforced concrete foundation, a structural steel frame, insulated steel panels, masonry walls, and a standing seam metal-and-membrane roof. Inside the facility, crews will build a raised-access floor system and partitions, along with electrical, plumbing, environmental, and communication systems. All systems are designed for sustainability, including energy efficiencies that meet high-performance principles. Likewise, secured spaces will follow standards outlined in Intelligence Community Directive 705, which aims to protect sensitive intelligence information.

“It’s a special and complex project with a lot of moving pieces that will need to come together in one area,” says Thareth Casey, USACE Project Manager. “When completed, it will be the biggest and most innovative building on the base.”

The decision to place JITTC at JBER came after a lengthy process that involved assessing the area’s ability to facilitate the mission and infrastructure, community support, environmental factors, and cost. JBER is home to a variety of military units and is tasked with providing air supremacy, surveillance, worldwide airlift, and agile support forces to project global power and global reach, as well as training and readiness oversight.

“It’s one of the biggest projects our district has seen and will be transformative for the base,” says Casey. “JITTC shows how important JBER is to Indo-Pacific Command.”

USACE closed the bid process in February and plans to announce a contractor by the end of June, with the goal to begin construction by midsummer. This multi-year project has an estimated completion date of fall 2029.

Airspace in the Anchorage area is heavily congested with JBER flights, commercial passenger and cargo aircraft arriving and departing Ted Stevens Anchorage International Airport, flights from Lake Hood Seaplane Base, and additional air traffic from Merrill Field. The smaller size of the north-south 16/34 runway meant JBER pilots often relied on the longer east-west 06/24 runway for large-frame aircraft, which led to further congestion. Extending the north-south 16/34 runway allows more military planes to depart and recover in air spaces that are less congested.

“Safety is extremely important,” says Daly Yates, USACE program manager on the runway project. “Strategically, Alaska—particularly Anchorage—provides top cover for the US.”

Construction crews have faced several challenges, including the second-highest snowfall on record in 2023-2024 and some of the highest rain events in the past twenty years. To keep the project moving forward, crews had to mobilize pumps to drain excess water and stabilize the site. USACE worked with JBER to ensure the construction activities met environmental standards and didn’t spread pollutants. In addition to dealing with excessive weather, crews needed to move a small mountain to expand the runway. To date, Kiewit has relocated nearly 12 million cubic yards of dirt along the 1,400-acre site.

In addition to extending the runway, crews will build two supporting taxiways, new shoulders, grading, drainage, and new lighting.

The runway extension is a collaborative effort between the Air Force Installation Mission Support Center, USACE Alaska District, JBER’s 3rd Operations Support and 673rd Civil Engineer Squadrons, and the Air Force Civil Engineering Center. The project, one of the largest ever undertaken by Pacific Air Forces, is on track to be completed by September 2026 and will cost around $360 million.

Though EAS is in a remote part of the state, it serves as an Air Force refueling station as well as an intercontinental emergency landing strip for commercial air traffic crossing the Pacific Ocean. Likewise, it is a receiving area for barges and other operations happening on the island. Given the sensitivity of marine mammals in the area, the 2025 construction period will only last 160 days, ending in October. Completion of the pier is slated for 2026 and will cost $176.7 million.

Various construction projects are underway at US Coast Guard Base Kodiak. Crews on the Nemetz Family Housing project are building fifty additional housing units divided between thirty-eight three-bedroom and twelve four-bedroom homes. The goal of the Nemetz Family Housing project is to meet the needs of families stationed in Kodiak. Housing construction began in September 2022 and is expected to be complete this year.

Tutor Perini Corporation is the prime contractor, with RSP Architects providing design and construction administration services. The cost of this project is not final as material costs and other expenses have increased over

the years.

The housing design incorporates sustainable features and promotes energy efficiency. The units include air-to-water heat pumps, hydronic floor heating, and LED lighting, which designers hope will help them meet the goal of a 30 percent reduction in energy use.

ore than 100 Associated General Contractors, or AGC, of Alaska members and friends donned cowboy hats and boots and climbed aboard the AGC Spring Train on April 26, the first Spring Train in five years. Attendees took the opportunity to network while enjoying snacks and drinks from Ship Creek Brewing and Tent City Taphouse, doing a little competitive bidding, and playing some AGC Bingo. All the while, the spring scenery rolled by on the trip from Anchorage to Indian and back.

- CGC Services, LLC

- Construction Machinery Industrial, LLC (CMI)

- Granite Construction Company

- North Star Equipment Services

- Spenard Builders Supply

- Swalling General Contractors, LLC

- TOTE Maritime Alaska, Inc.

- Alaska National Insurance Company

- Drake Construction Inc.

- Marsh McLennan Agency

- Minn-Alaska Transport

- N C Machinery Co.

- Anchorage Sand & Gravel Co., Inc.

- Big State Mechanical, LLC

- Carlile

- Davis Block & Concrete

- Knik Construction Co., Inc.

- Shoreside Petroleum, Inc.

- Sourdough Express, Inc.

- Hiland Construction LLC

- Northern Air Cargo

- Ritchie Bros. Auctioneers

- Top Shelf Realty, LLC

- Aurora National Insurance (DBA Bond Babes USA)

- TDL Staffing

- Ship Creek Brewing Co.

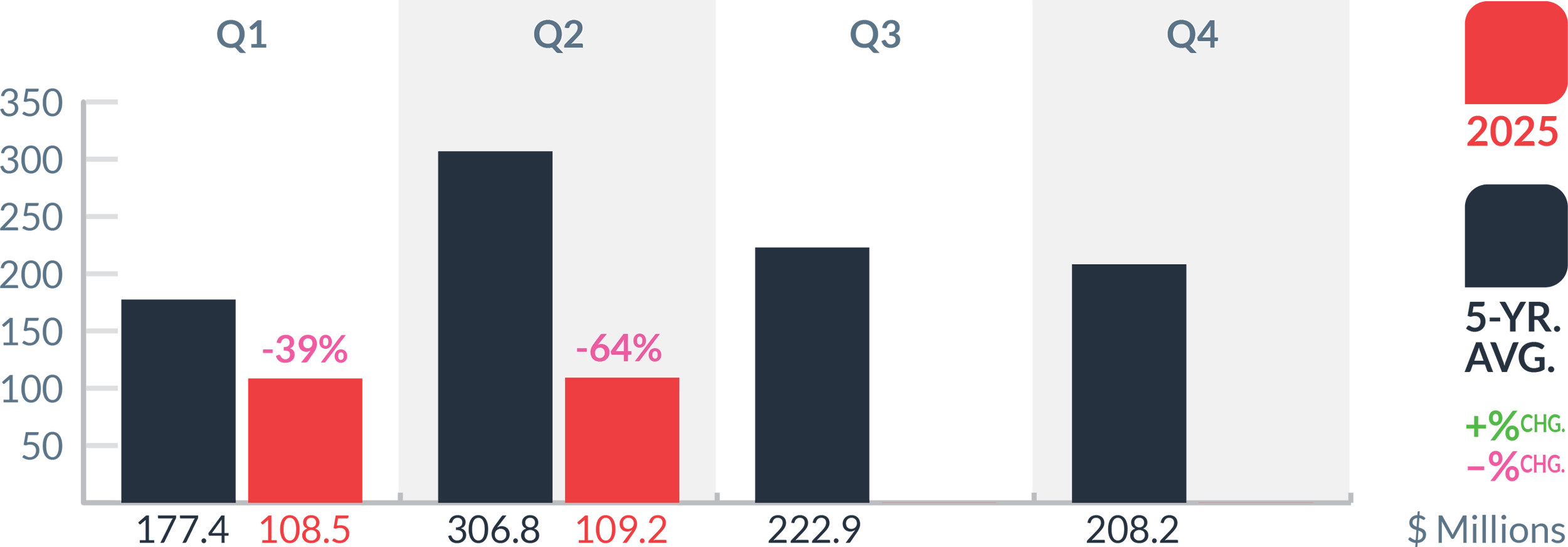

resident Donald Trump has signed several Executive Orders related to US trade policy, including setting tariffs on imported goods from multiple countries, with the intent to protect American industries. Many countries countered by issuing their own tariffs. Together, the actions are disrupting global supply chains and have created an atmosphere of uncertainty, which is affecting many businesses in all of Alaska’s major industries, construction included.

Supply issues reach beyond Canadian lumber. “Nearly all of the aluminum that’s used in the United States comes from abroad, particularly from Canada,” says Simonson. “While a lot of aluminum goes into the automotive or aerospace industries, aluminum is important for architectural features in building. Then there is a wide range of appliances, equipment, and machinery used in the construction industry that comes from a variety of countries. Much of it comes from China, so the proposed 145 percent tariff on China— or whatever percentage it ends up being—will definitely drive up the cost of a lot of construction projects.”

The reaction from other countries to US tariffs is a primary concern for the construction and other industries, he notes.

“My biggest concern about the tariffs is not cost; construction has certainly dealt with big cost jumps in the past, most notably in the year or two following the pandemic. But I’m really concerned about what other countries are doing and what they will do in reaction to our tariffs. First, the tariffs will affect many kinds of businesses. Manufacturers that depend on imported parts or components will be less competitive just because their costs are higher. But then, if other countries put tariffs on US products, that could close the door to some of those products,” explains Simonson, adding that AGC has already seen Canadians—on their own initiative—reacting strongly to the tariffs.

Chief Economist, Associated General Contractors of America

“Immigration so far this year seems to be running at zero. While Alaska was probably getting less immigration than other states, having it totally cut off will be another hardship, as construction is more dependent on foreign-born workers than many other industries. I would suspect that for some of the seasonal jobs, that is particularly true,” says Simonson.

“Another concern is the abrupt cut-off of federal funds through the cancellation or freezing of contracts and grants for many kinds of research for all sorts of projects, not specifically for construction projects necessarily, but when the owners suddenly find they don’t have the funds to do construction to support whatever they were going to put up that building for. All of these things create a huge amount of uncertainty and cause owners, whether public agencies, investors, or companies building for their own use, to put some projects on hold,” explains Simonson. “However, for the most part, contractors have not reported that they’ve been affected yet. Recession seems to be everywhere except in the data. However, there are plenty of reports, whether news stories or corporate owner reports, that investors are holding off on investments.”

“What I hear contractors talk about is putting larger contingencies into their bids and encouraging owners to agree to earlier purchases of materials if they’re the sort of thing that can be stored,” shares Simonson. “If there is a site that can store materials, the contractors will need an agreement on who will pay for the use of that storage facility, the insurance that may be required, and the risk that the specifications or the quantity might turn out to be wrong. So many projects go through modification as they’re underway or after the initial signing of a contract. Those are some of the things that are worth discussing between owners and contractors and always worth having communication on as early and as frequently as possible between the designers, the fabricators, the contractors, and the subcontractors. While those rules apply in any case, the consequences of not following them are greater in this setting.”

To assist contractors in uncertain times, AGC of America has created several resources.

AGC has an advocacy news website at advocacy.agc.org/news, which can be a useful resource for following anything in the administration that is important to your business, including executive orders, regulations, and tariffs.

The AGC Legislative and Regulatory Priorities 2025-2026 report, found online at advocacy.agc.org/priorities, outlines federal legislative and regulatory priorities that will promote and advance the construction industry.

AGC members can stay informed by weekly newsletters from Construction Advocacy in Action. Sign up at agc.org/news/newsletter.

And finally, a frequently updated page outlining recent tariff news and helping contractors navigate challenges related to possible tariffs: agc.org/tariff-resources-contractors.

“The US economy and its construction industry have shown incredible resilience over the last five-plus years. So, while I do feel that the risk of a downturn, even a recession, has gone up a lot, I believe construction will continue to grow after what may be a rough patch,” concludes Simonson. “We’ll move on. We’ve done it before.”

t’s not often that a construction project gets completed one-and-a half years ahead of schedule, but according to SECON Project Engineer Jared Mackey, the collaboration between everyone involved in recent Juneau Airport improvements allowed them to finish in May, instead of on the projected completion date of September 2026.

“It’s not just one party that deserves praise for getting this project completed in a timely manner,” he says. “The City and Borough of Juneau’s ability to work with the airport’s tenants and contractors, and DOWL Engineers’ ability to deal with constant planning and rephasing was a big help, as was the commitment of SECON and the project’s subcontractors to working long, hard hours to complete a year and a half ahead of schedule.”

The $14.7 million project included rehabilitating the Part 121/135 apron and remaining overnight, or RON, parking apron, which were both more than thirty years old.

“The timing of the project followed the Alaska Department of Transportation’s asphalt pavement and classification, which identified the apron surfaces as needing replacement, and the apron work and RON work were combined into a single project for efficiency,” explains Juneau Airport Project Manager Mike Greene.

During the design phase of the project, the airport intentionally created a lineal schedule, identifying each of the twelve project work phases, and assigning a work period for each.

“As we had hoped, SECON elected to address the work by overlapping work phases, which allowed them to work in more than one phase area at a time, effectively shaving an entire year off of the schedule,” says Greene.

“These aprons/ramps abut one another and cover an area of approximately 23 acres. The last major rehabilitation occurred more than twenty years ago, with more recent repairs occurring in areas around the jet bridges,” says Greene. “The pavement on both aprons/ramps had been determined to be well beyond its useful life and had been showing signs of deterioration from heavy aircraft use.”

While crack sealing and temporary repairs had been done over the years as a stopgap measure, they could no longer address all areas of failing pavement, including potholes, spalling, ponding in low spots, and drainage/catch basin fatigue.

The project also addressed the existing apron lighting mounted on the south side of the terminal that created cockpit glare and cast shadows from parked aircraft that prevented the illumination of work areas around the aircraft.

“This project introduced new lighting away from the terminal near the ends of the jet bridges that will cast light directly downward to fully illuminate the areas used by ground crews,” says Greene.

“In the past, every night from late-May to mid-September, gate parking was at capacity,” says Greene, noting that air carriers often used the freighter parking across the ramp as a RON spot between freighter arrivals.

“Air carriers also towed their 737 RON aircraft to the north ramp, though the pavement was not suitable for that type of aircraft,” adds Greene. “Additionally, small aircraft parked on the outside parking spots on the 135 ramp were displaced at night to allow the 737 [aircraft] sufficient space to be towed to/from the area until a gate became available.”

Work on the RON included construction of subsurface structural subbase and base course, the installation of a reinforced concrete hardstand, the placement of asphalt paving to meet weight standards for large, scheduled passenger aircraft parking, and striping and marking associated with parking and lead-ins.

“The worn and damaged asphalt surfaces have now been replaced, which directly benefits every aircraft that traverses these aprons, as well as improves the efficiency of snow removal operations,” says Greene. “Juneau now has a dedicated hardstand for use by any aircraft that needs to overnight (without tying up a passenger boarding bridge/gate) and provides a parking position for any aircraft experiencing a mechanical [issue].”

SECON coordinated its construction work with other airport projects: JIA’s replacement of the passenger boarding bridge at Gate 5, as well as Alaska Airlines’ replacement of passenger boarding bridges at Gate 3 and Gate 4, and expansion of Alaska Airlines’ air-cargo hardstand.

“There were numerous airport stakeholders affected by our work, including Alaska Seaplanes, Ward Air, Coastal Helicopters, Alaska Airlines, and Delta, so it took constant communication and planning to find a way to keep everyone happy,” says Mackey. “We also live in a rainforest, so we had to take advantage of non-rain days, working 14- to 18-hour days and weekends.”

SECON also took long lead times into account and started procuring the items it would need in 2023. To make sure they had enough workers, and to complete the airport improvements on time, the contractor juggled other projects.

“We have labor shortages here like they have everywhere else because the workforce is getting smaller,” says Mackey. “We only have so many union employees, and have a number of projects going on at the same time, including in Haines and Ketchikan, so we had to share our workforce. Sometimes that meant flying in certain people for different aspects of work and flying them out again when it was done.”

The full project included thirty SECON employees as well as roughly sixty subcontractor employees. Associated General Contractors, or AGC, of Alaska member companies who worked as subcontractors on the project include Compass Construction, LLC; DOWL; and Pacific Asphalt, LLC.

Photo provided by Caliber Construction Alaska

Photo provided by Caliber Construction Alaska

n the face of a global pandemic that stalled many businesses in 2020, Caliber Construction Alaska LLC turned uncertainty into opportunity. What began as a series of side projects during the COVID-19 slowdown has grown into a dynamic civil contracting firm.

Founded by Colton LeVasseur, Caliber Construction Alaska is rooted in a legacy of earthwork expertise. A fourth-generation construction industry professional, LeVasseur started his career working for his family’s business in 2009 before making the leap into Operating Engineers Local 302. He worked construction jobs in the summer and worked toward his pilot’s license in the winters, leading to a career as a commercial pilot. But in 2020 the demand for high-quality site work pulled him back to the ground for good, and Caliber was born.

“What started as small contracting jobs during the pandemic quickly grew into something much larger,” says LeVasseur. “Soon, I had to step away from flying to keep up with the volume of work. That’s when Caliber Construction Alaska really took off.”

“We’re not afraid of complex or high-risk jobs,” says LeVasseur. “Where others might walk away or add a hefty contingency, we lean in. Our skilled team, niche tools and equipment, technology, and hands-on leadership allow us to deliver exceptional results efficiently and safely.”

Photo provided by Adam Erdmann

Brian Van Abel of Swalling General Contractors, the project’s principal contractor, praised Caliber Construction Alaska’s performance.

Van Abel credits the project’s success to the two companies working closely to develop a work plan, which was carefully coordinated between the owner and military, allowing completion of the work in fewer than three months.

“Caliber’s culture of professionalism impresses me,” continues Van Abel. “Caliber shows up to the site when they say they will, they provide solutions to issues as they arise, and they execute their scope of work on time. Caliber is a trusted civil subcontractor for Swalling. We’ve completed several projects together and have several new projects starting as well.”

While Caliber Construction Alaska has proven its ability to tackle large scale infrastructure jobs, the favorite role of the company team is site preparation: getting a site ready so vertical contractors can hit the ground running.

“We love being the team that clears the way, literally and figuratively, for builders,” LeVasseur says. “We help them stay ahead of schedule and deliver high-quality foundations for successful projects.”

“There’s a real need to bring new talent into the trades,” explains LeVasseur—who is 33 years old. “We’ve built a culture where mentorship is expected. Our seasoned team members take pride in showing the ropes to the next generation.”

From hands-on leadership to smart recruitment, Caliber Construction Alaska is creating a workforce that’s as forward-thinking as the technology they use, utilizing global positioning systems and machine control.

Founder, Caliber Construction Alaska LLC

Photo provided by Caliber Construction Alaska

“We take pride in the diversity of our work and the impact we’re making in our communities,” Bates says. “We’re constantly growing, always improving, and that’s exciting to be part of. Colton has instilled a ‘roll-up our sleeves’ culture across the board. Everyone from office staff to the field hands chips [in] wherever it is needed. It’s unlike what I have witnessed in the past for this industry.”

As an Associated General Contractors, or AGC, of Alaska member since the company’s inception, Caliber Construction Alaska leaders value the relationship AGC is building across the industry.

“AGC has been a great platform for networking and collaboration,” Bates adds. “It helps us stay connected and build partnerships that matter.”

“We’re proud of what we’ve built, but we’re just getting started,” says LeVasseur. “There’s a lot of work ahead.”

n March, more than 150 high school students from across Alaska gathered in Anchorage to test their abilities in hands-on technical and leadership challenges during the state’s SkillsUSA conference. The three-day event, held March 26 through 28, marked a growing return for SkillsUSA in Alaska, as students competed in dozens of different trade competitions ranging from welding and electrical wiring to video production and cosmetology.

Winners represented Alaska at the SkillsUSA National Championships in Atlanta, Georgia, from June 23 to 27.

“The National Competition is absolutely mind-blowing,” says Keith Hodson, SkillsUSA Alaska director and a career and technical education coordinator at the Anchorage School District, of the 2024 competition. “Imagine thirty football fields filled with competitions: that’s what SkillsUSA is like. The energy is electric—young adults proudly showcasing their skills. Alaska has one of the smallest populations in the nation, and I know our students felt overwhelmed; I did too.”

“We’re so grateful to our teachers, parents, and business sponsors for making this possible,” Hodson says. “Students in these programs are learning real-world skills, building résumés, and practicing public speaking. They’re gaining confidence, and that’s priceless.”

The list of competitions spans both technical and leadership categories, from welding sculpture and diesel mechanics to job interview simulations and t-shirt design. As participation and interest increases, so will the number of competitions that are offered. According to Lori Harmon, president of the SkillsUSA Alaska board and an industry leader with GHEMM Company in Fairbanks, SkillsUSA can tailor competitions to the needs of the state.

Board President, SkillsUSA Alaska