Associated General

Contractors of Alaska

Associated General

Contractors of Alaska

8005 Schoon St.

Anchorage, AK 99518

907-561-5354

Fax: 907-562-6118

www.agcak.org

Associated General Contractors of Alaska

Jenith Ziegler

ChemTrack Alaska, Inc.

Pearl-Grace Pantaleone

HDR Alaska Inc.

Alicia Amberg

Associated General Contractors of Alaska

Christine A. White

R&M Consultants, Inc.

Heather Sottosanti

Big State Mechanical, LLC

Marcus Trivette

Brice, Inc.

Johnathon Storter

Meridian Management, Inc.

Tasha Anderson

Managing Editor

Rindi White

Editor

Monica Sterchi-Lowman

Art Director

Fulvia Lowe

Art Production

James K Brown

Graphic Designer

BUSINESS STAFF

Charles Bell

VP Sales & Marketing

907-257-2909 cbell@akbizmag.com

Janis J. Plume

Senior Account Manager

907-257-2917 janis@akbizmag.com

Christine Merki

Senior Account Manager

907-257-2911 cmerki@akbizmag.com

501 W. Northern LIghts Blvd., Ste 100

Anchorage, AK 99503

The Alaska Contractor is published by Alaska Business Publishing Co. Inc. for the Associated General Contractors of Alaska. Contents of the magazine are not necessarily endorsed by AGC of Alaska or Alaska Business Publishing Co. All rights reserved. Copyright 2024 by the Associated General Contractors of Alaska. For information about articles in this edition or for permission to reproduce any portion of it, contact Alaska Business Publishing Co.

Design by James K Brown

8005 Schoon St.

Anchorage, AK 99518

907-561-5354

Fax: 907-562-6118

www.agcak.org

Associated General Contractors of Alaska

Jenith Ziegler

ChemTrack Alaska, Inc.

Pearl-Grace Pantaleone

HDR Alaska Inc.

Alicia Amberg

Associated General Contractors of Alaska

Christine A. White

R&M Consultants, Inc.

Heather Sottosanti

Big State Mechanical, LLC

Marcus Trivette

Brice, Inc.

Johnathon Storter

Meridian Management, Inc.

Tasha Anderson

Managing Editor

Rindi White

Editor

Monica Sterchi-Lowman

Art Director

Fulvia Lowe

Art Production

James K Brown

Graphic Designer

BUSINESS STAFF

Charles Bell

VP Sales & Marketing

907-257-2909 cbell@akbizmag.com

Janis J. Plume

Senior Account Manager

907-257-2917 janis@akbizmag.com

Christine Merki

Senior Account Manager

907-257-2911 cmerki@akbizmag.com

501 W. Northern LIghts Blvd., Ste 100

Anchorage, AK 99503

The Alaska Contractor is published by Alaska Business Publishing Co. Inc. for the Associated General Contractors of Alaska. Contents of the magazine are not necessarily endorsed by AGC of Alaska or Alaska Business Publishing Co. All rights reserved. Copyright 2024 by the Associated General Contractors of Alaska. For information about articles in this edition or for permission to reproduce any portion of it, contact Alaska Business Publishing Co.

Design by James K Brown

AGC MEMBER

AGC MEMBER

Alaska Electrical Contractors, LLC

$7,680,506

Rampart RPSU Project On Site Construction

Fullford Electric, Inc.

Fullford Electric, Inc.

$3,598,857

U-Park ES Renovation Phase IV

Trost Construction, Inc.

Trost Construction, Inc.

$1,296,810

Northern Region Electrical Maintenance & Repair

Fullford Electric, Inc.

Fullford Electric, Inc.

$507,500

Nome Boiler Replacement Project

Scott’s Heating & Plumbing Services

$239,930

HC Contractors, LLC

HC Contractors, LLC$23,796,618

Elliott Hwy. MP 18-29 Resurfacing

QAP

QAP

$12,588,872

Solid Waste Facility Cell 4 Construction (Rebid)

Central Environmental, Inc.

$5,738,694

Tanana Middle School Exterior Renovation

Callahan Construction Company

Callahan Construction Company

$2,206,000

Denali Highway Culvert Replacement

Great Northwest, Inc.

Great Northwest, Inc.

$1,765,394

Design/Build Siding and Window Replacement, Mt. View

Wolverine Supply, Inc.

Wolverine Supply, Inc.

$1,687,000

Kuskokwim Campus Health Sciences Renovation

TC Construction

$1,242,011

Residential Well and Septic Systems Installation Northway and Tetlin

Pioneer Peak Industries

$461,965

Spring Glade RSA Road Improvements

M & M Constructors, LLC

M & M Constructors, LLC

$389,554

Hamme Pool Roof Repairs

A&A Roofing Company, Inc.

A&A Roofing Company, Inc.

$325,000

Utilities Steam Line Repairs Utilidor H and F

Aaron Plumbing & Heating Co.

Aaron Plumbing & Heating Co.

$324,000

Becker Ridge RSA Road Improvements

Groundhogs, LLC

Groundhogs, LLC

$316,440

Haystack RSA Road Improvements

M & M Constructors, LLC

M & M Constructors, LLC

$294,635

Pickleball Court Development

Groundhogs, LLC

Groundhogs, LLC

$161,987

Combined Elliot/Steese/Dalton Nome Creek Hwy. Pumping

RNR Construction Co, LLC

$160,500

SWL Tank Removal and Replacement

Hubbard Excavation

Hubbard Excavation

$139,632

Replacement of Boiler Parts at AHFC Birch Park I (Rebid)

Denali Mechanical, Inc.

Denali Mechanical, Inc.

$131,500

Granite Construction Company

Granite Construction Company$9,622,769

AISD Faciltiies – Admin Building

Dawson Construction, Inc.

$3,398,968

Meals Hill Park Development Phase I

Drennon Construction & Consulting, Inc.

Drennon Construction & Consulting, Inc.

$3,159,095

Lawson Creek Rd. Reconstruction

Coogan Construction Co, LLC

$1,579,890

Providence Valdez Medical Center Level 1 EPS Generator Replacement

Sturgeon Electric Co, Inc.

Sturgeon Electric Co, Inc.

$1,267,915

Glacier Highway Lena Area Water Line Replacement

North40 Construction Corporation

$661,000

Douglas D Street to 1st St. Reconstruction

Admiralty Construction, Inc.

$572,146

Craig WWTP Roof Replacement

Building Specialties, Inc.

$456,990

2024 Area Wide Paving Phase I

Colaska, Inc.

Colaska, Inc.

$398,784

35 Mile Off Road Vehicle Parking Lot

Enco Alaska, Inc.

$323,010

Schoenbar Park Playground Renovation

Dawson Construction, Inc.

$294,937

Mendenhall River Community School Boiler Replacement

IP Mechanical Contractors, LLC

$284,976

Tenakee Springs 2024 DERA Power Plant Upgrade

Sturgeon Electric Co, Inc.

Sturgeon Electric Co, Inc.

$221,660

Mass Excavation, Inc.

Mass Excavation, Inc.$43,303,169

Elmore Road: Abbott Rd. to Providence Dr. Pavement Preservation

QAP

QAP

$9,874,913

Water Improvements Glenn Square PRV Facility

Roger Hickel Contracting, Inc.

Roger Hickel Contracting, Inc.

$6,299,100

Construct E. Hidden Hills (Phase 1) and E. Caswell Lakes Road Improvements

Granite Construction Company

Granite Construction Company

$4,557,273

Miscellaneous Construction Services 2024-2027

Spernak & Son, LLC

$4,500,000

DOT & PF Annex Building Earthquake Repairs

Brice Builders, LLC

$3,659,000

West Lakes Blvd. Reconstruction

AHTNA Construction & Primary Products Corp.

AHTNA Construction & Primary Products Corp.

$2,733,125

Construct Bogard Rd. Booster Station

Orion Construction, Inc.

$2,006,474

Construct East Smith Rd. Ext. Upgrade and Pathway

Neeser Construction, Inc.

Neeser Construction, Inc.

$1,774,353

McKenna Bros Paving, Inc.

$1,656,898

Starner Bridge Improvements Project

Swalling General Contractors

Swalling General Contractors

$1,425,000

Annual Road Maintenance Road Service Area (RSA 9) – Midway

Battleground, LLC

$1,075,217

Cosntruct North Erica Dr. Road Improvements

Northern Asphalt Construction

$873,356

Construct Knik Knack Mud Shack Road Improvements

Granite Construction Company

Granite Construction Company

$791,630

Nelson Lagoon RPSU Project Modular Power Plant Assembly

Electric Power Constructors, Inc.

$782,721

Jupiter and Diana Ave. Road Improvements

Dirtworks, Inc.

Dirtworks, Inc.

$755,596

2024 Lilac Ln. Roadway Improvements

Peninsula Construction, Inc.

$637,765

APD Elmore Roof Renovation

Anchorage Roofing & Contracting, Inc.

Anchorage Roofing & Contracting, Inc.

$624,000

Power Tech Electric

$580,506

Annual Road Maintenance Rd. Service Area (RSA 29) – Greater Talkeetna

Alaska Resource Group, LLC

$579,020

Annual Road Maintenance Rd. Service Area (RSA 20) – Greater Willow

D&S Road Services

$567,900

Port of Alaska Modernization Program North Floating Dock Replacement

Duwamish Services, LLC

$537,000

Construct Settlers Bay Dr. at Crocker Creek Fish Passage Improvements

Meier Excavation, LLC

$488,470

Lore Road Traffic Calming Petersburg St. to Cherrywood Cir.

JTA Construction, LLC

JTA Construction, LLC

$471,775

Sullivan Arena Earthquake Repairs

SD Construction, LLC

$234,877

Naknek School Rooms 118 and 119

H Construction, LLC

$185,000

Septic Lift Station Repair Project

Peninsula Construction, Inc.

$148,520

West 100th Ave. Traffic Calming and Pedestrian Improvements

Spernak & Son, LLC

$142,669

MESSAGE

ver the past half century, the story of Alaska has been shaped by the oil and gas industry, and the heart of that industry has been centered in Prudhoe Bay.

Today it is easy to hop in your pickup and drive to the end of the Dalton Highway, 495 miles north of Fairbanks. Fifty years ago this spring, past and current Associated General Contractors, or AGC, of Alaska members embarked on the mission to bring road access from Livengood to Prudhoe Bay with construction of the Haul Road, now called the Dalton Highway.

In the spring of 1974, Alyeska Pipeline Service Company began to award contracts for construction of the road from the Yukon River to Prudhoe Bay. A Fairbanks Daily News-Miner article from April 5, 1974, details the strategy of splitting the 358-mile project into sections, which allowed it to be completed in just five months. Green-Associated Pipeline, a joint venture of Associated Pipeline Contractors, Inc. and Green Construction Company, along with Burgess Construction Co., Morrison-Knudsen Corporation, and General-Alaska-Stewart, were the prime contractors, with subcontracts awarded to Alaska firms including DNH Development Corporation, Tundra Contractors, Inc., Brice, Inc., Alaska Diamond Drill Contractors, Inc., Morgan Construction, Inc., and J.R. Clinton Company.

The completion of the Haul Road, and a few years later, the Trans Alaska Pipeline System, have left a physical reminder of what can be done by a determined construction industry and helped make Alaska the state it is today. The workforce that built the initial megaprojects through the heart of the state continued to maintain that infrastructure and embark on other development projects, from Point Hope to Ketchikan. Over time our industry has matured, evolved, and sometimes consolidated, but the can-do attitude of that original generation that built the Haul Road remains part of our culture and who we are.

Until then, I encourage you to take a moment this season to think about the work that was happening fifty years ago on the northern third of our state—and to also think about what we need to do as an industry and an association to keep the spirit and perseverance of that time alive and well in our daily operations.

As we look forward to the next generational project that will shape Alaska, remember where we came from. The challenges today are similar, and we have the tools to meet them. Through training, workforce development, advocacy for common sense policies and regulations, and celebration of our industry to the public, we will be ready to take on the trial of that job with our Alaska resources and local support.

ike the old saying goes, there are four seasons in Alaska: early winter, mid-winter, late winter, and construction season. I won’t comment on the first three, but safe to say we’re big fans of the fourth one. We go into our busiest time of year excited, energetic, and eager to build Alaska. But we must also keep safety at the forefront of everything we do.

Our association has always advocated for the responsible development of Alaska’s resources. We uphold the highest environmental and safety standards, aiming to balance economic growth with environmental stewardship. Ambler Road is not just a construction project but a gateway to mineral opportunities that could significantly benefit both local communities and national interests.

Photo provided by Alicia Amberg

Nearly half of the NPR-A’s land is now deemed off-limits for development. This move significantly reduces opportunities for construction projects tied to oil and gas production, which provide thousands of jobs in Alaska. These projects not only involve direct construction jobs but also create demand for related services and infrastructure development.

Imposing these restrictive new measures during a period of high global energy demand is bad energy policy and hurts the potential for growth and investment in our sector. AGC of Alaska will never stop pushing back against these nonsensical regulations that hurt our sector and our economy.

Kristen Kolden, President

Travina Stuart, Accounting Technician

4.9 Mile Haines Hwy.

Haines, AK 99827

Phone: 907-766-3408

kristen@hiexak.com

travina@hiexak.com

HiEx Construction, Inc. is a general contractor based in Haines. Work includes government and community civil projects not limited to highway, utilities, excavation, site preparation, crushing, drilling and blasting, blast consulting, and rock slope stabilization.

Sturgeon Electric Company, Inc.

Kim Caple, Estimator/Project Manager

Alan Growden, District Manager

1301 E. 64th Ave.

Anchorage, AK 99518

Phone: 907-344-0321

kcaple@myrgroup.com

agrowden@myrgroup.com

sturgeonelectric.com

Full-service commercial electrical contractor.

Alec Turner, Owner

Amanda Bohman, Strategic Partnerships Coordinator

3316 Shell St.

Fairbanks, AK 99701

Phone: 907-458-7286

alaskangranite@yahoo.com

alaskangranite.com

We specialize in granite, marble, and quartz products for kitchens, bathrooms, fireplaces, bars, and more.

Be Happy Property Services

Jacob Bishop, Owner

Tim Russell, GM

1118 E. 71st Ave.

Anchorage, AK 99518

Phone: 907-223-8055

behappyhomes@gmail.com

behappyhomes.tim@gmail.com

behappyps.com

We provide full-service maintenance and construction for commercial and residential properties. We perform snow plowing, construction, landscaping, and excavation services for the properties we take care of.

D & B Concrete, LLC

Dan Olson, Owner

Heidi Olson, Office Manager

13540 S. Knik Goose Bay Rd.

Wasilla, AK 99623

Phone: 907-715-4483

dblawnandsnow@yahoo.com

dbconcreteak@yahoo.com

dandbconcrete.net

Commercial concrete contractor offering the following services: flatwork, monolithic slabs, footings and walls, structural concrete, curb and gutter, sidewalks, and concrete paving. Established in 2002.

*Referred by Jeff Miller, Cruz Construction

Fairbanks Concrete Takeout

Jerome Byrd, Owner

937 24th Ave.

Fairbanks, AK 99701

Phone: 907-699-8765

fairbanksconcretetakeoutllc@gmail.com

Concrete pour, finish, and removal. Small excavation work.

JP&E Enterprises

Jonathan Davis, Owner

16939 Mercy Dr., Unit B

Eagle River, AK 99577

Phone: 907-691-6742

jondavis@jpandeenterprisesllc.com

jpandeenterprisesllc.com

We are a small Alaska Native-owned general contracting company that specializes in commercial tenant improvements. We also do sub-work as we self-perform steel stud, drywall, paint, all the way to finishes. Looking to grow our network and help give opportunities to Alaskan Natives and the Native communities.

*Referred by Rashaud Joseph, AK DOT&PF Civil Rights Office

MIH Construction

Khelly Moore, Owner

7160 W. Windsor Dr.

Wasilla, AK 99623

Phone: 907-444-6818

khellymoore@gmail.com

Commercial tile, drywall, finishes.

Nu Flow Alaska, LLC

Joe Jaime, President

Rock Phelps, Project Engineer

1301 E. 71st Ave.

Anchorage, AK 99518

Phone: 907-677-2145

jejaime@nuflowak.com

rphelps@nuflowak.com

nuflowalaska.com

Rehabilitate the inner infrastructure of deteriorated or failing water piping systems using an array of cured-in-place epoxy pipe lining solutions.

Rashaad Esters, Procurement Manager

3510 Spenard Rd., Ste. 100

Anchorage, AK 99503

Phone: 907-793-3000

resters@cookinlethousing.org

cookinlethousing.org

At Cook Inlet Housing Authority (CIHA), we focus on building affordable rental housing. CIHA designs and builds its developments to work for specific neighborhood contexts and resident groups. We also invest in commercial corridors as a way to revitalize neighborhoods.

*Referred by Scott Vierra, North Star Equipment Services

DeWALT

Jeff Walters, Account Manager—Alaska

4610 W. Museum Dr.

Wasilla, AK 99623

Phone: 907-203-9085

jeff.walters@sbdinc.com

Dewalt.com

Manufacturer of construction tools, anchors, storage, and fasteners. The company’s more than 50,000 diverse and high-performing employees produce innovative end-user inspired power tools, hand tools, storage, digital jobsite solutions, outdoor and lifestyle products, and engineered fasteners to support the world’s builders, tradespeople, and DIYers. The company’s world class portfolio of trusted brands includes DEWALT, CRAFTSMAN, STANLEY, BLACK+DECKER, and Cub Cadet.

Dorsey & Whitney LLP

Marisa M. Bavand, Partner

Jennifer Porter, Sr. Marketing & Business Development Manager

1031 W. Fourth Ave., Ste. 600

Anchorage, AK 99501

Phone: 907-276-4557

bavand.marisa@dorsey.com

porter.jennifer@dorsey.com

dorsey.com

Dorsey is an international firm with more than 575 lawyers in the United States, Canada, Europe, and Asia. Many of the world’s most successful companies count on Dorsey to help them prosper in a highly competitive world.

Jagged Sky Benefits Group

Frank Bailey, President

2900 Boniface Pkwy., Ste. 210

Anchorage, AK 99504

Phone: 907-276-4357

frank@jaggedsky.co

jaggedsky.com

We craft benefits packages to help employers recruit, retain, and reward their employees.

*Referred by Chris Pobieglo, Business Insurance Associates

King’s Custom Design

Jessica Alvarez, Owner

2190 N. Broadway Dr.

Palmer, AK 99645

Phone: 907-521-9669

customizeit@kingscustomdesignsllc.com

kingscustomdesignsllc.com

KCD offers specialized engraving solutions utilizing technology, including CNC routers, CO2 lasers, and fiber lasers, to cater to a wide array of materials from plastics to stainless steel. Beyond engraving, we extend our services to include sublimation on a variety of products such as signage and safety vests, ensuring a broad spectrum of customization options to meet your unique needs.

*Referred by Reyes Alvarez, JD Steel Co., Inc.

Pac-Rim Building Supplies, Inc.

Chris Gerondale, Business Development

John Cahill, President

3901 Raymond Ave. SW

Renton, WA 98057

Phone: 907-251-3700

chrisg@pacrimbuilding.com

jcahill@pacrimbuilding.com

pacrimbuilding.com

Pac-Rim sells a wide variety of building materials from lumber and drywall to pressure-treated marine pilings and from blast-rated windows for military bases to bathroom accessories. We use our 30,000-square-foot warehouse on 3.5 acres in Renton to consolidate the building materials so they will ship as efficiently as possible.

Temporary Wall Systems Anchorage

Peter Laliberte, Owner

4870 Cape Seville Dr.

Anchorage, AK 99516

Phone: 907-931-1199

peter.laliberte@tempwallsystems.com

tempwallsystems.com

Temporary installation and rental of dust containment systems for commercial, institutional, and healthcare building renovation projects.

Featured photo: CLC booth at the 2023 Anchorage Golf Tournament provided by AGC of Alaska.

t’s been said there are two seasons in Alaska: winter and construction season. National Work Zone Awareness Week, April 15 through 19, is an early season reminder that, during construction season, motorists need to take special care when going through construction zones to pay attention, slow down, and exercise caution.

“Work Zone Awareness Week is an opportunity for us to emphasize the importance of safe driving practices in and around construction zones,” says Alaska Department of Transportation & Public Facilities Commissioner Ryan Anderson. “Our dedicated crews work tirelessly to improve and maintain Alaska’s transportation infrastructure, and it is imperative that motorists do their part to keep them safe.”

In an effort to reduce fatalities, USDOT implemented a National Roadway Safety Strategy that includes five elements: safer people, safer roads, safer vehicles, safer speeds, and better post-crash care.

The approach acknowledges human mistakes as well as human vulnerability and designs a redundant system to protect everyone.

Work Zone Awareness Week organizers offered a few tips for improving work zone safety:

- Reroute. Avoid traveling through work zones, if possible. Otherwise, allow extra time for possible delays and travel safely.

- Avoid distractions. Workers are focused on their jobs in work zones; be vigilant behind the wheel to safely travel through the work zone by putting down your phone and paying attention while driving.

- Reduce speed. Follow speed limits to make driving through narrow lanes and lane shifts easier and safer for you while keeping workers safe.

- Be aware of workers. The work area is often very close to travel lanes, so please be considerate: Take care and slow down when you see workers.

- Watch for pedestrians and bicyclists. Work zones often restrict where nonmotorized road users can travel. In 2022, 145 persons on foot and bicyclists lost their lives in work zone crashes.

- Give large vehicles space. Narrow lanes, unexpected lane shifts, and longer braking distances are challenges for large vehicles. Allow extra space for them to safely navigate work zones. In 2022, 30 percent of fatal work zone crashes involved commercial motor vehicles, which include large trucks and buses.Take care around large construction vehicles, which may be driving at slower speeds to enter and exit the work area.

- Stay alert. Be prepared for sudden stops. Work zones may cause unexpected slowdowns. In 2022, 21 percent of all fatal work zone crashes involved rear-end collisions.

or Andy Davidson, safety is all about family.

“Everyone obviously wants to get home to their family, but having that mentality, that it’s family first, I think, puts safety up front,” he reflects. “Anytime someone [from my crew] needs or wants time off, there’s never a question. You’ve got to know people’s limits and not overwork them.”

The Mass Excavation, Inc. project superintendent manages as many as forty-five to sixty active personnel on challenging projects, ranging from the Seward Highway MP 75-90/Portage Curve Multimodal Connecter to improvements at Merrill Field Airfield, for which he was recognized with the Mayor’s Certificate of Excellence in 2018.

“I’ve been lucky enough to have my same crew—most of them—for over ten years, so we all rely on each other,” he says. “I’ve had good operators and people to learn from, so that definitely helps. I won this award, but honestly, it’s them keeping me in check and me keeping them in check.”

Keeping an eye on each other is crucial when Davidson’s crew tackles projects like Mass Excavation’s current work on the Seward Highway—considered one of Alaska’s most dangerous highways. Here, relentless traffic, unpredictable weather, and the hazards inherent in night work contribute to the difficult conditions Davidson contends with.

The biggest issue he navigates on the project, though, is public safety, according to Cody Troseth, Mass Excavation project manager.

“With a job of that size and scale, Andy coordinates and manages all the subcontractors, all of his workers, and he deals with the state. But in terms of safety, the biggest thing on the Seward Highway is the public, and the safety of the public,” Troseth explains. “There’s particular planning you have to do to make sure you can keep traffic moving in a safe manner. You’re basically redoing a brand-new highway on the curve while the public is still in motion, daily.”

Davidson’s outstanding leadership on that project won him additional responsibility, including being selected as the superintendent for the $90 million Seward Highway Portage Curve Multimodal Connector.

To keep his crew focused, Davidson holds daily safety meetings where he emphasizes that day’s focus, soliciting information and concerns from everyone involved, and he collaborates with safety managers to run through complex jobsite activities.

Project Manager, Mass Excavation

Sometimes his crew sees the unexpected. On the Indian project, he received a message over his radio that a nearby house was on fire.

“I raced down there and, yeah, it was pretty crazy. As a kid, you’re always taught to feel the doorknob. I did that, kicked the door in, and there was a lady in bed—she couldn’t walk. So, I crawled over to her and carried her out of there,” he says. “It was pretty intense. But it is kind of amazing how the stuff you learn as a kid, that you never think you’d actually use, came to my mind in that situation.”

“I can’t stress enough how much Andy’s ability to deal with the public and to work with the state brings to the table,” Troseth says. “He definitely has a different way of looking at projects; he’s always thinking about the public.”

rom working on the construction of the Long-Range Discrimination Radar, or LRDR, project in Alaska to making wildlife crossings safer in Idaho, STG Pacific, LLC has taken on a wide range of unique projects since its start in 2016.

A subsidiary of Calista Corporation and sister company to STG Inc., STG Pacific was formed to take on federal work in the 8(a) market in Alaska and other locations.

Though the company originally got its start in piling work and specialty foundations, President Brian Midyett says it has since morphed into vertical, horizontal, design/build, heavy industrial, and specialty concrete structures.

“Our sister company, STG Inc., was working in remote Alaska for about twenty-seven years before it was purchased in 2013 by Calista Corporation,” he says of the company’s beginnings. “Because we shared some similarities with them in the work that we were doing, we utilized some of the strength of that company to help us get our first contracts.”

Managing Principal of Architecture, RIM Architects

“The people at STG Pacific are really good communicators and have a very professional approach to their work,” says James Dougherty, managing principal of architecture at RIM Architects. “They have a similar style to us in that they don’t tell professionals what to do; they ask for their opinions to get the smartest people in the room to contribute to the best solutions. That’s a real key to having a strong, strategic partnership.”

STG Pacific was instrumental in the construction of Alaska’s LRDR Equipment Shelter project in Clear, where it constructed a high-altitude electromagnetic pulse, or HEMP-shielded foundation to protect the facility against electromagnetic events, such as the detonation of a nuclear weapon.

“The foundation cost $24 million alone,” says Midyett, noting that STG Pacific was the only contractor to finish ahead of schedule on the multi-faceted LRDR project.

“The results of [STG Pacific’s] hard work and pre-emptive planning were nothing short of amazing,” says Lieutenant Colonel Mark J. DeRocchi, retired deputy commander for the US Army Corps of Engineers, or USACE, Alaska District, on the work done on that foundation project.

“That was a really cool project, and it’s been a big success,” says Midyett of the project completed in November 2023. “They have a camera set up on the overpass and they’ve been seeing a lot of wildlife traffic.”

The project is expected to reduce animal-vehicle collisions in the area by 80 percent.

President, STG Pacific LLC

“The core of our business is our senior management team, many of whom have worked for large Fortune 500 contractors before coming here to build this business up,” says Midyett, who worked with Kiewit Pacific Co. for fifteen years and with global engineering firm CH2M, before it’s acquisition by Jacobs, for a decade. “Our management team has worked in this industry, and in business, for a long time. We also have a lot of Millennials in our workforce, and we put a real emphasis on succession planning and career mapping for our young leaders,” he adds. “That’s one of the reasons why younger people work here—we’re trainers of people. We provide a lot of training with the goal of bringing up the next generation to ensure a sustainable business.”

As a longtime member of Associated General Contractors, or AGC, of Alaska, Midyett says STG Pacific appreciates the help the company has received from the organization, which has allowed it to continue to build on its success.

“AGC is a great networking tool, and also a great advocacy organization when dealing with tough issues like labor and collective bargaining agreements,” says Midyett. “They even went to bat to make us essential workers during the COVID crisis. They are there to help—all the time.”

ssociated General Contractors, or AGC, of Alaska joined the Alaska Chamber and other Alaska trade associations and business advocacy groups—ten in all—in co-hosting the inaugural Alaska Resources Day in Washington D.C. The event celebrated the success of resource industries operating in Alaska; as US Senator Lisa Murkowski described it in an April 18 speech on the US Senate floor directed at President Joe Biden, the range included “everything from oil and gas to mining, to seafood, and tourism. It was a good day spent educating folks about Alaska’s commitment to and, really, our record—a very strong record—of responsible development to benefit Alaska and the nation.”

While in Washington, the group of trade associations and business advocacy groups representing Alaska took part in several other events, including a lunch with chiefs of staff from all Alaska Congressional delegation members, the Alaska State Society Cherry Blossom Festival, a panel discussion focusing on Alaska that was part of the Greater Tacoma Chamber of Commerce’s annual D.C. Fly-In, and a national briefing that included updates from the US Chamber of Commerce, AGC of America, National Mining Association, US Travel, and others.

CEO, Alaska Chamber

The event was also sidelined by an announcement that the Administration was going to announce two decisions restricting resource development in Alaska: a rejection of the Ambler Access Project, which would build a road to the Ambler Mining District, and a decision to tightly restrict development within the National Petroleum Reserve-Alaska, or NPR-A.

Regarding NPR-A, “The new rules threaten Alaska’s economy. They ignore input from many communities, including those in rural parts of the state, which impact Alaska Native people and shareholders. These rules will result in us relying more on oil from foreign countries, many of which openly oppose US interests,” Kati Capozzi, CEO of the Alaska Chamber, said in a joint press release about the NPR-A rule. “There is good reason Alaska’s Congressional Delegation has stood together in opposing this rule. With growing global turmoil, this is the worst time to tie our economic hands behind our back.”

Murkowski, in her address to Biden April 19, advocated a shift in perspective about tapping Alaska’s resources.

“Given a choice between China and Africa or Alaska for minerals, it should be Alaska every time. And given a choice between Iran and Russia and Venezuela or Alaska for oil, it should be Alaska every time,” Murkowski said.

Photo provided by Lynden

Photo provided by Lynden

n 2023, Associated General Contractors, or AGC, of Alaska member Alaska Marine Lines, or AML, and Lynden Logistics provided shipping transport for a container of used medical equipment and relief supplies sent from Whittier to the African port of Ghana in support of Alaska-based nonprofit Alaska Medical Missions, or AMM.

The container was shipped from Whittier to Seattle, then loaded onto a ship for the longest leg of the journey to Africa. From Ghana, it was shipped to Burkina Faso, where the medical supplies were divided and sent to a variety of locations, some headed to a military-run hospital to care for those injured as a result of political unrest in that country.

AMM, an associate agency that is part of Christian Health Associates, Inc., works to improve healthcare around the world by partnering with organizations to collect surplus and fully functional medical supplies from Alaska—mostly organizations on the Southcentral Alaska road system but sometimes from medical facilities around Alaska that are upgrading equipment and sometimes from private practices moving, closing, or upgrading equipment. Some supplies come from private donations; families whose loved ones have died, donating beds or opened and unused medical supplies. AMM then distributes the supplies to a global network of partners, often packing them into suitcases of doctors or health professionals headed to volunteer around the world. A list of needed medical supplies is posted at AMM’s website, alaskamedicalmissions.org/donate-supplies. Occasionally, AMM is able to pack a shipment of beds or dental chairs into a shipping container, which was the case with the Burkina Faso-bound equipment.

AMM Director

“Lynden companies continue to make the daunting task of global shipping streamlined for AMM with shipments to our partners around the world. We count Lynden as one of the key partners in making our mission work, sending aid to the nations where even the most basic medical supplies save lives. We are deeply grateful for Lynden’s latest support of this shipment to Burkina Faso,” says David Rurik, AMM director.

Lynden Logistics International Operations Manager Brandie Holmes says the Alaska Railroad played a part in the shipping journey, too.

“The railroad covered the shipping costs from Anchorage to Whittier, and we partnered with AML to donate our services from Anchorage to Ghana,” Holmes says.

Photo provided by Alaska Medical Missions

Photo provided by Alaska Medical Missions

Rurik says the cost to AMM to ship the medical containers is generally around $5,000. The organization relies on individual donors and corporate sponsors to fund its operations so the recipient organization can receive the supplies for free. The recipient organization is typically responsible for the shipping cost, but AMM’s shipping partners, including Lynden, have participated in reducing the shipping costs immensely in the past few years.

Lynden strives to give back to the communities it serves with financial contributions and by donating in-kind services to various causes. Lynden companies and employees support hundreds of charitable and community organizations, including United Way, Habitat for Humanity, the YMCA, and local food banks.

laska was still a territory in 1958 when Wes and Jewell Cruikshank first opened the doors of Hoffer Glass Company in Fairbanks. Today, the company remains family owned and operated and continues to serve the Fairbanks community.

With a strong focus on customer satisfaction, Hoffer Glass provides quality energy-efficient doors and windows tailored to the unique needs of Fairbanks’ challenging weather.

Today, as president of Hoffer Glass, Emily Cheysobhon carries on the family tradition of quality work and customer service.

“That experience helped me develop confidence. I worked side-by-side with my dad and aunt for twenty years and couldn’t do what I do now without the guidance they provided,” she says.

Cheysobhon’s dad appointed her president of the company a few years before his death to prepare her for running the company. She owns the business with her husband, Chris Cheysobhon, who serves as vice president.

“We’ve had numerous family members who have started their careers here. My siblings have both worked here over the years, as well as several cousins. After getting their start at Hoffer, some of my cousins and my brother are now working on high-rises and commercial jobs in the Lower 48. One of my cousins worked in the Lower 48 on large commercial jobs for several years, but he returned to Fairbanks about one and a half years ago to help out in our shop.”

Estimator and Salesperson, Hoffer Glass Company

“We started building those in 1997, piggybacking off of one of our suppliers by making changes to the hardware in the glass, adding locks at the top and bottom and a few other features to make the windows airtight, which is so important for our climate. You won’t find these features on other windows,” Cheysobhon explains. “Our goal is to offer the best customer service and the best products to all our customers, both residential and commercial.”

“I began working here in 2012 when I was 26,” he says. “I started in the shop for a few years, left for another glass company and then got called back here to go into estimating and sales in 2015. Working for a family business, I would say that it’s a comfortable environment here. We aren’t as formal and we all get along really well. Also, Emily is open to input and suggestions. We don’t have sales quotas to meet and we’re proud of the products we sell, informed enough to speak to the science of the products, and the quality speaks for itself.”

For a family-owned local company, word-of-mouth advertising is everything. “Our number one priority is to take care of our customers—even if a repair is needed past warranty,” says Cheysobhon. “We also rely on networking within our community, which is one of the benefits of being an AGC member.”

Hoffer Glass has been a member of Associated General Contractors, or AGC, of Alaska since February 4, 2017. As for customer satisfaction, Fairbanks resident Pat Frymark is sold on the company.

Hoffer Glass Company Customer

Hoffer Glass guided Frymark on how to reduce the overall cost.

“We determined I could remove the windows myself and I could also do the finishing work, like moldings,” explains Frymark. “Even more impressive, I went to them with questions for items I was uncertain about, and rather than being annoyed with me asking numerous questions, they took me into their shop and showed me how they put the moldings together. They also told me where to get the same products they use at a lower cost. Their concern was making sure I was comfortable. They’ve gone above and beyond what is expected with customer service. I wouldn’t go anywhere else.”

laska has been hit hard by the opioid crisis that has plagued the United States since the late ‘90s. Overdose deaths in Alaska have been rising for many years, with only a small decrease experienced in 2022. However, the decrease abruptly ended in 2023. As reported in the Anchorage Daily News, Alaska led the nation in year-over-year increase at approximately 40 percent in overdose deaths from November 2022 to November 2023.

The culprit has been opioids, with fentanyl being involved in approximately 94 percent of all opioid-related overdoses in Alaska. Fentanyl is a strong synthetic opioid that can be used for pain relief in surgical procedures. However, the worrisome fentanyl is illicit—it is being pressed into counterfeit pills to mimic real prescription medications. The Drug Enforcement Administration, or DEA, reports that at least 70 percent of seized illicit drugs contain fentanyl.

Overdose deaths inflict a toll on families, workplaces, communities, and economies. Parents, grandparents, and every person connected to children and young adults must learn the risks of fentanyl and the meaning of “One Pill Can Kill”—the DEA’s message about the prevalence and danger of fentanyl.

laska has been hit hard by the opioid crisis that has plagued the United States since the late ‘90s. Overdose deaths in Alaska have been rising for many years, with only a small decrease experienced in 2022. However, the decrease abruptly ended in 2023. As reported in the Anchorage Daily News, Alaska led the nation in year-over-year increase at approximately 40 percent in overdose deaths from November 2022 to November 2023.

The culprit has been opioids, with fentanyl being involved in approximately 94 percent of all opioid-related overdoses in Alaska. Fentanyl is a strong synthetic opioid that can be used for pain relief in surgical procedures. However, the worrisome fentanyl is illicit—it is being pressed into counterfeit pills to mimic real prescription medications. The Drug Enforcement Administration, or DEA, reports that at least 70 percent of seized illicit drugs contain fentanyl.

Overdose deaths inflict a toll on families, workplaces, communities, and economies. Parents, grandparents, and every person connected to children and young adults must learn the risks of fentanyl and the meaning of “One Pill Can Kill”—the DEA’s message about the prevalence and danger of fentanyl.

- Prescription medications for both on- and off-the-job injuries are a potential source of new, persistent opioid use in construction, especially relating to musculoskeletal injuries. With the high frequency and severity of sprain and strain injury rates, it is important to educate employees about alternatives to opioid pain management and the dangers of purchasing illicit medications for pain relief.

- Surgery is a leading gateway to new, persistent opioid use. An article that I co-authored, posted by the International Foundation of Employee Benefit Plans titled “Optimizing Outcomes and Containing the Costs of Surgery” highlighted that between 8 and 18 percent of patients become persistent opioid users, depending on the type of surgery. Opioid-sparing Enhanced Recovery After Surgery, or ERAS, protocols use up to 90 percent fewer opioids than conventional surgical methods.

- It is imperative for employees and dependents enrolled in union- or employer-sponsored health benefit programs to know non-opioid medications exist.

- Become informed and be an advocate for yourself or any other family member scheduled for any medical, surgical, or dental procedures.

- Drug deactivation and at-home disposal products help properly dispose of leftover opioid pills after prescriptions for on- and off-the-job injuries and surgeries. Research shows 90 percent of patients receiving pain medication do not properly dispose of the leftover pills. This increases the household risk of overdose deaths due to the diversion of the leftover pills.

Employers are encouraged to teach employees about the risks of opioids and to share resources to help employees and families protect themselves from the risks of unnecessary opioids and the dangers of fentanyl in today’s illicit drugs.

Employers and families are encouraged to stock naloxone in first-aid kits for emergency use in case of an overdose. Naloxone is an opioid antagonist and reverses the effects of an overdose. Free training is available at safeproject.us/life.

he 33rd Alaska State Legislature ended with the Senate adjourning just before the midnight deadline on May 15, while the House continued to work on bills. Despite some last-minute challenges and tension in the House, the state budget was settled, with an operating budget of approximately $6 billion in state funds and a capital budget of around $4 billion in state and federal funds.

- $174.4 million for a one-time Base Student Allocation increase to $680/student

- $7.3 million for pupil transportation

- $5.2 million for K-3 reading focus

- $30 million for full community assistance

- $914.3 million for a Permanent Fund Dividend and energy relief payment of $1,655 per person in October

- $4 million grant to Anchorage for homeless housing

- $5.2 million for Head Start to match federal funds

- $1.5 million for Senior and Disabilities grants

- $1.5 million for Adult Day Services grants

- $7.5 million for grants to childcare providers

- $5 million for personal care services wages

- $3.7 million to support Council on Domestic Violence and Sexual Assault

- $1.3 million for hiring of highway and aviation staff

- $68 million for deferred maintenance at UA campuses and K-12 schools

- $30 million for professional housing and weatherization

- $8 million for Alaska Department of Transportation & Public Facilities harbor funds

- $7.5 million for food security measures

- $75 million for infrastructure projects around the state.

The Legislature passed HB 50, Carbon Capture, Utilization, and Sequestration, which was a top priority for Governor Mike Dunleavy. The bill primarily addresses the sequestration, or storage, of carbon in depleted gas and oil reservoirs in Cook Inlet. This initiative has drawn interest from Japan, which is exploring the possibility of compensating Alaska for this service.

The Senate Resources Committee integrated a few policies into HB 50. These include provisions for the release of Cook Inlet seismic data to facilitate developers’ access, the regulation of Cook Inlet natural gas storage prices by the Regulatory Commission of Alaska and the introduction of a funding mechanism known as reserve-based lending.

HB 307, the Integrated Transmission Systems initiative, was another priority for the governor. The primary aim of this bill is to establish a modernized and efficiently managed transmission grid for the Railbelt region stretching from Homer to Fairbanks. This endeavor seeks to eliminate “wheeling rates,” which represent the charges incurred as electricity flows through different segments of the transmission infrastructure owned by various entities, essentially creating tolls for electrons. By removing these fees, the bill aims to foster open access for independent power producers, promoting the integration of renewable energy sources such as solar, wind, geothermal, and hydroelectric power into the grid. Additionally, HB 307 proposes to increase the surcharge that the Regulatory Commission of Alaska can levy to support its regulatory services and establishes an Alaska Energy Authority, or AEA, Board.

At our weekly Legislative Affairs Committee meetings, we review bills that require monitoring, support, and/or opposition or neutrality. Overall, we were able to discourage movement and provide alternative solutions on several bills that could have negatively impacted on our industry.

The AGC Legislative Affairs Committee organized a well-attended and successful fly-in event to the State Capitol in February with the aim of advocating for AGC priorities by engaging with key legislators and policymakers while raising awareness about crucial industry-related matters. More than twenty AGC members traveled to Juneau to educate lawmakers on issues that are vital to the well-being of the construction industry, which is essential for its growth and sustainability.

A huge thank you to our hard-working Legislative Affairs Committee, including co-chairs Meg Nordale, Regina Davis, and lobbyist Dianne Blumer.

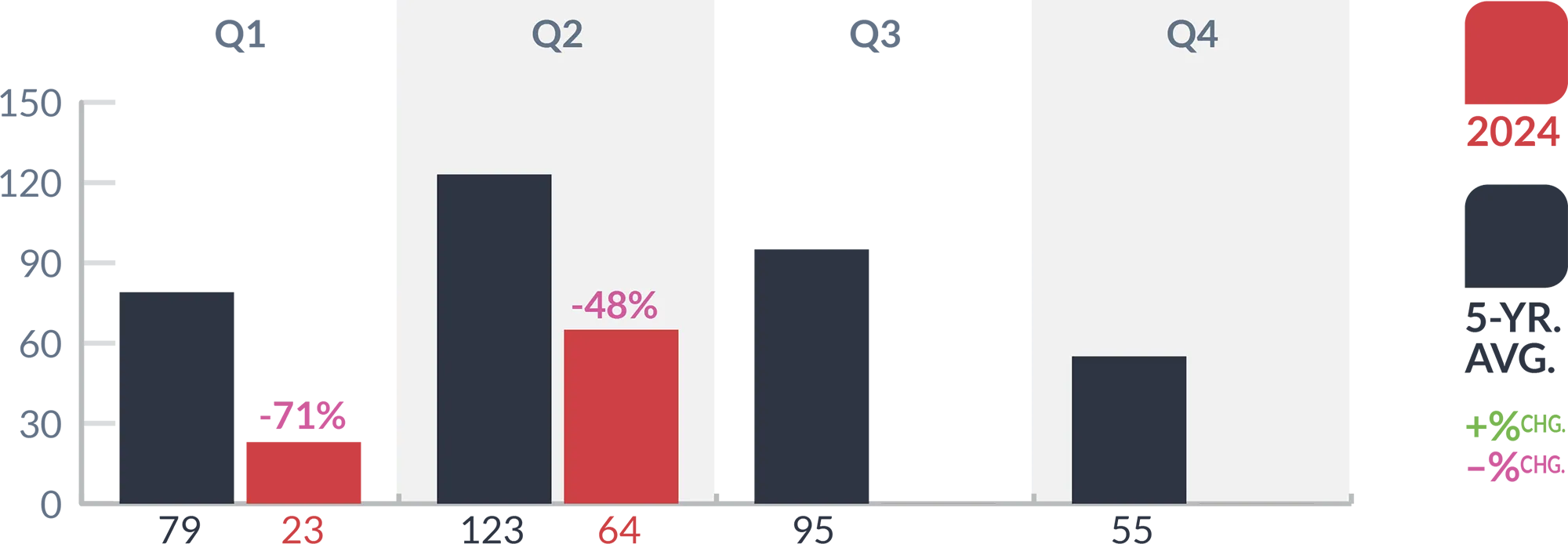

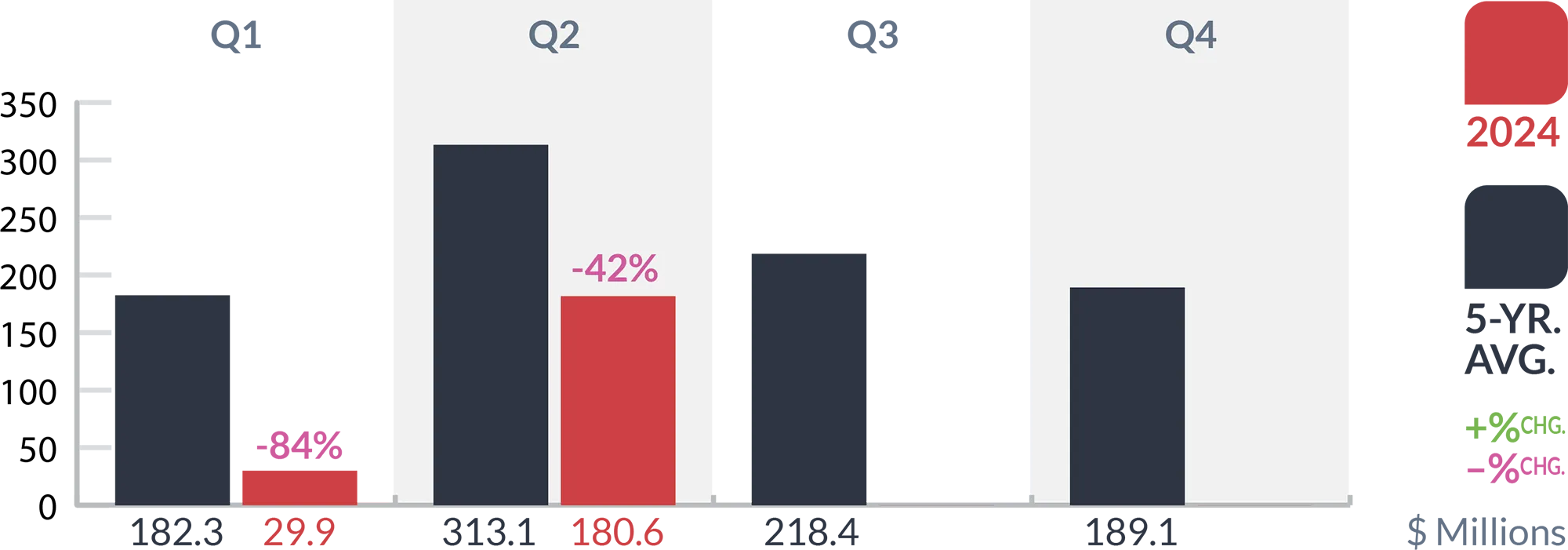

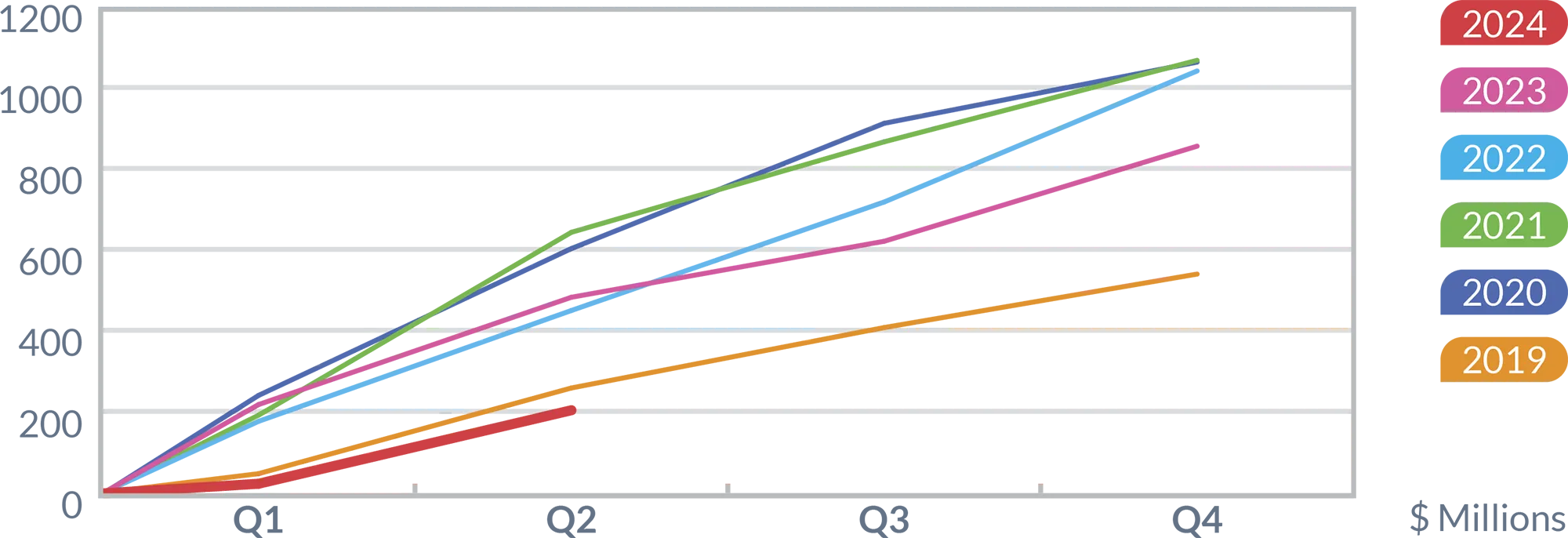

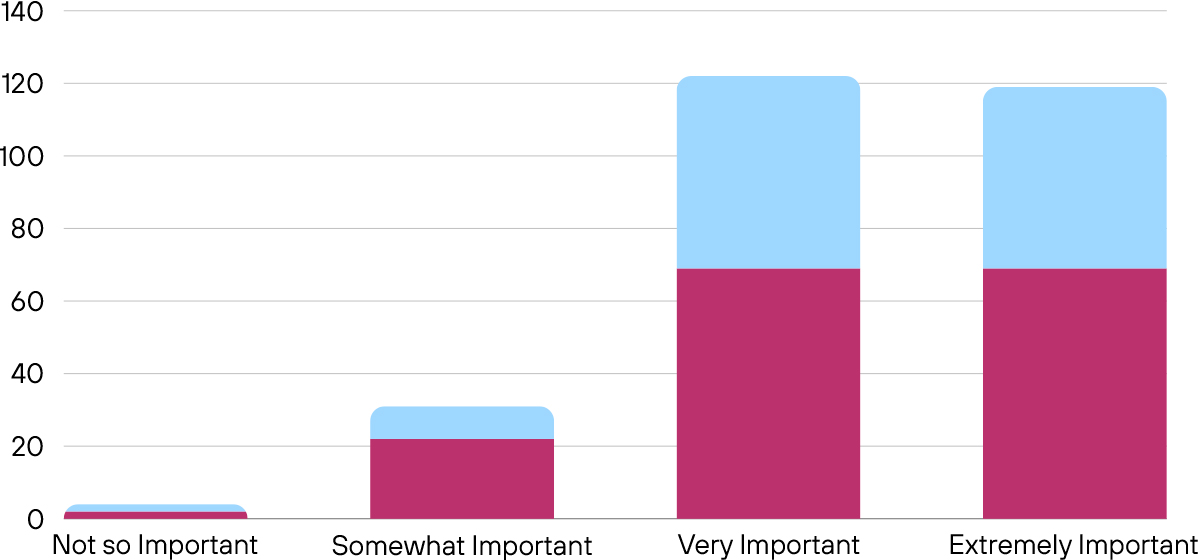

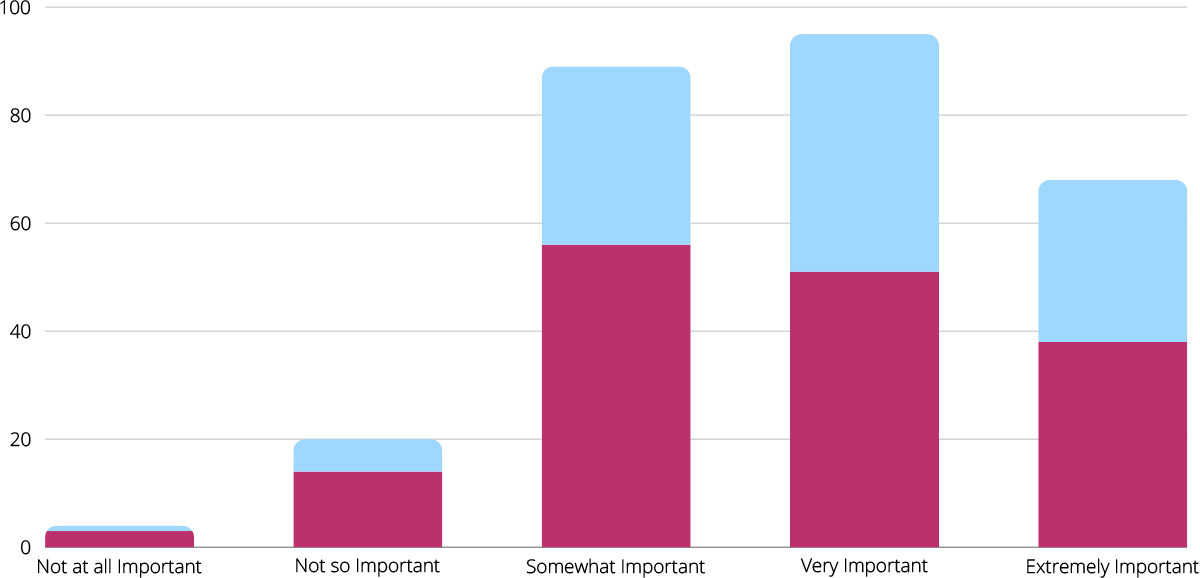

Interesting

Insights

he construction industry is integral to Alaska’s industrial, commercial, residential, and infrastructure development. But like other Alaska industries, it is short on workers, particularly Alaskans.

To help fill those openings, the Associated General Contractors, or AGC, of Alaska collaborated with the Construction Industry Progress Fund, or CIPF, to create WeBuildAlaska. The workforce development campaign is designed to educate potential employees from Alaska—“Obviously, we want Alaskan candidates to fill those roles,” says AGC Training and Workforce Development Director Ruby Oatman—or the Lower 48 about the benefits of a career in the construction industry and encourage them to join.

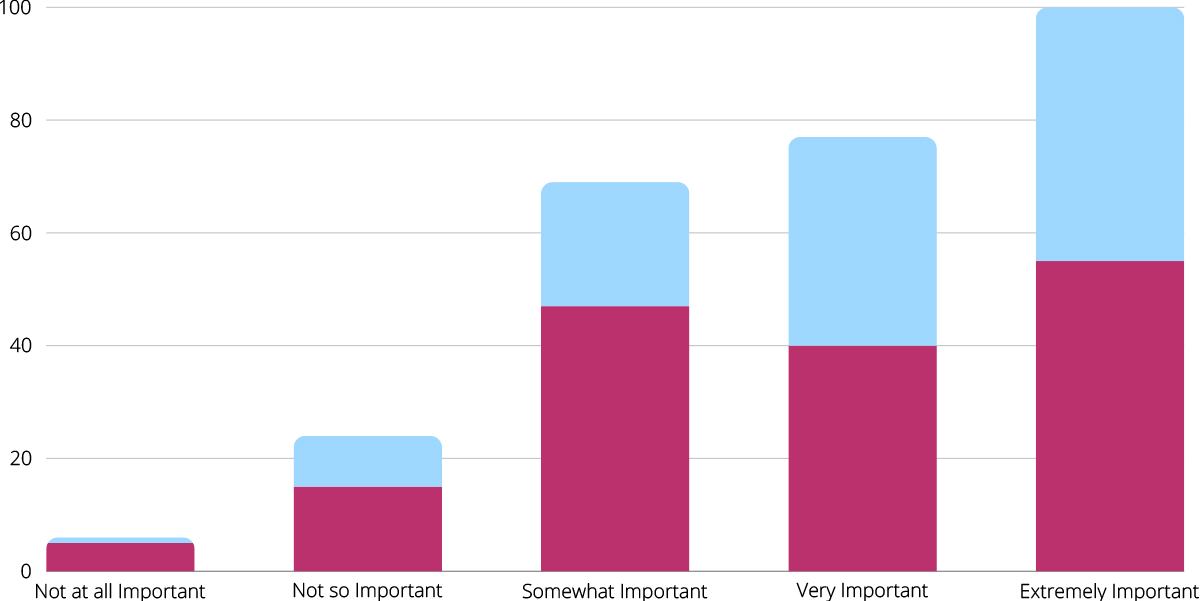

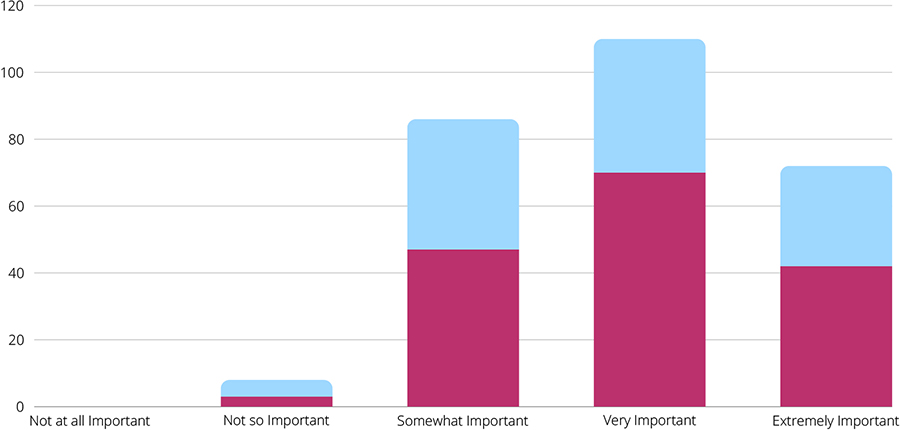

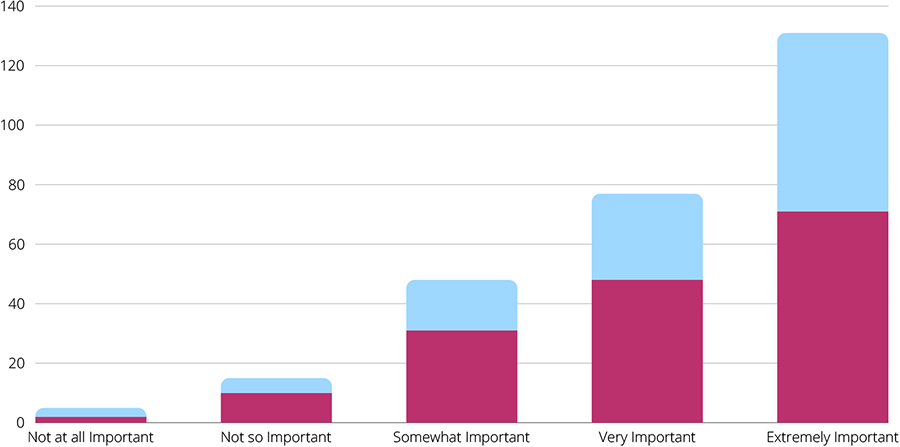

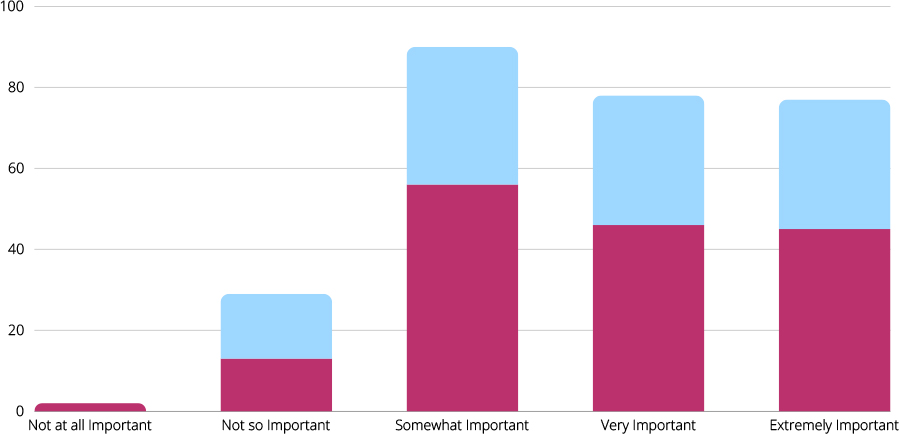

In January, WeBuildAlaska hired Wheelhouse 20/20, a digital marketing firm, to help with its efforts. Wheelhouse 20/20’s first task was surveying current, potential, and former workers to ascertain attitudes and perceptions about the industry.

Wheelhouse worked with WeBuildAlaska to identify current industry workers for phone interviews. It also created an online survey it promoted to people between the ages of 18 and 50 in Alaska and key states in the Lower 48, says Linzie Reynolds, director of strategy for Wheelhouse 20/20.

Survey Respondent

“It’s vital that an employer cares about their workers more than just how productive they are,” one interviewee told Reynolds, who conducted the interviews.

These non-compensatory factors are things Oatman says will help WeBuildAlaska differentiate Alaska from other states, like Oregon and California, where industry wages are similar.

“Through the survey, we were able to see that we can maybe market to other things that Alaska is unique in, like the Alaska beauty and scenery and wildlife, and the lifestyle of being able to work for the summer and travel for the winter,” she says. “These are things we can focus on instead of just salary.”

Ninety percent of current and former workers said they were introduced to the industry by a friend or family member who worked in construction.

Director of Strategy, Wheelhouse 20/20

Training and Workforce Development Director, Associated General Contractors of Alaska

They’re also working to highlight just how varied and long-term a career in the industry can be.

“That’s something we really focus on when we go in to do outreach, showing all the different fields that you can go into in the construction industry,” Oatman says. “Not just the manual work, but there are human resources, accounting, safety’s a big one. There’s so much upward mobility. You can start off as a laborer and you can work hard and eventually own your own business or become the CEO of a successful construction business. Additionally, construction skills are transferable. You can go anywhere in the world and get a job—but we would prefer they stay in Alaska.”

Update

Preparation

ork started in November 2023 on the Santos Oliktok dock expansion, which will provide expanded capability and capacity for a seawater treatment plant that will serve Pikka Oil Field development. Led by general contractor Cruz Construction, Inc., the civil portion of the dock was completed last winter, despite delays caused by the weather.

Australia-based oil company Santos owns 51 percent of the onshore Pikka Oil Field. Spain-based Repsol owns the remaining 49 percent share. The project sits just east of the Colville River and the National Petroleum Reserve-Alaska. Repsol conducted exploration in the ‘10s that indicated the Nanushuk formation below Pikka may hold more than 750 million barrels of oil, with the possibility of much more oil lying in the geologic layer just below the Nanushuk formation. Total output from the Pikka project could reach 400 million barrels, with an estimated daily output amounting to 15 percent of oil carried through the Trans Alaska Pipeline System to Valdez, a flow estimated to last thirty years. Santos and Repsol hope to begin production in 2026.

Subcontractor North Star Equipment Services, or NSES, and Cruz Construction then installed 2,935 sheet pile at Oliktok Point, about fifty miles west of Prudhoe Bay, and Cruz Construction backfilled the dock with gravel. Alaska Test Labs was also a subcontractor on the project.

“The weather was really bad this winter, so we were three to four weeks late on ice-road season, which put a lot of schedule pressure on the project,” says Matt Jones, North Slope operations manager for Cruz Construction. “This was a difficult project to accomplish in one year from a planning perspective, and it was a question if it even could be completed with the weather making things so difficult.

“All things considered, the project came together really well,” he continues. “We finished the majority of work that was dependent on the ice road structure three to four weeks before we had to be off the ice.”

Installation of the sheet pile took about two months, though prepping and building the needed templates began in October 2023, according to Randy Beltz, vice president of NSES Operations.

“There were inherent challenges—which all contractors this past winter season faced—because weather held up the start of the project,” he says. “But weather always tends to be an issue working in the Arctic.”

“Everybody out there, from our employees to the people from Santos and Cruz Construction, worked well together to execute the job about as flawlessly as possible,” says Beltz of the largest job NSES has done in its 60-year history.

This summer, Cruz Construction will thaw and recompact the gravel, which is expected to take about a month.

“While the dock will be finished, the barge grade associated with this work will not be completed until next summer,” says Jones, noting that that project will entail pumping out the seawater, reworking the barge grade material, filling it with water, and cutting pile to open it up.

A 200- x 400-foot barge will then be towed to the area, filled with water, and sunk to create a permanent berth filled with gravel on which the seawater plant will sit. The plant is scheduled to be installed in 2025.

“We appreciate Santos’ investment in Alaska. It was an absolute pleasure working with their leadership team on this challenging, time-sensitive project,” adds Jeff Miller, president of Cruz Construction.

“We were originally subcontracted to vibratory drive roughly 669 casings in wet hole locations to stem the water flow so that PGI could set the pile and slurry it in,” says Beltz. “However, because the wet holes weren’t as prevalent as first assessed, we had to switch gears and basically become a drilling subcontractor for PGI, drilling out the holes for the piles they were going to set and slurry.”

“You never know what the underground conditions will be until you get there,” he explains. “It required a pretty drastic switch in gears, but our crews were able to go with the flow. We’re here to provide PGI and Santos with whatever services they need, and our flexibility in being able to change gears or directions provided a real benefit to our clients. We’re adaptable as heck.”

“We went into the project knowing that if casings didn’t need to be installed, we could offer this up as an alternative so that PGI didn’t need to bring in additional equipment and people to run it,” says Beltz, noting that the companies had worked out this scenario ahead of time, with NSES providing rates for drilling and completing holes versus casing holes. “We could just change out the attachments to go from driving pile to drilling holes.”

Vice President of Operations, North Star Equipment Services

“As far as our portion of the project, it is completed as far as drilling,” says Beltz, noting that there is still work to be done in winter 2025 as part of the multiyear project. “It’s a great project, and we found that being adaptable was key to completing our part of the job. We hope to continue to offer whatever Santos and their construction partners need to support this project.”

fter a gap of three years, the Alaska Department of Transportation and Public Facilities, or DOT&PF, Construction Career Day was back and better than ever at the Alaska State Fairgrounds in Palmer May 1.

Around 800 middle and high school students from Anchorage and Matanuska-Susitna Borough school districts attended the morning event, where they learned about opportunities in the construction industry and had a chance to connect with various employers, from the Alaska Division of Forestry to the International Brotherhood of Electrical Workers. Home-schooled students and those from alternative schools were invited to take part in the afternoon. The goal, says Zhenia Peterson, DOT&PF Civil Rights Programs and compliance specialist, is to get students to start thinking about their future before they graduate.

The May 1 event included more vendors than typical, Peterson says, and many wanted to provide hands-on activities for the students. Many students came away with tin and metal toolboxes and miniature sawhorses they built at the event, along with hard hats, safety vests, beanies, and loads of stickers and informational materials.

While Peterson acknowledged that not all students who attended are likely to go into trades, if the event prompts one in ten to consider a construction career, it’s a win.

n the realm of architecture, engineering, and construction, or AEC, every project tells a story. From the initial concept to the final ribbon cutting, each step is a chapter in a narrative of innovation, creativity, and problem-solving.

Similar to a captivating movie, the progression of an AEC project can be crafted into an award-winning entry that captivates the judges and leaves a profound impression. Both require careful planning, attention to detail, impactful photography, and a compelling narrative arc that captivates the audience.

Just like a cinematic experience that guides audiences through highs and lows, your award submission should transport judges into the world of your project, immersing them in the scope, its challenges, triumphs, and ultimate success. So, grab your popcorn and let’s dive into the process of turning your project into a blockbuster.

Just like staging a plot to a movie, your project needs a compelling backstory to engage the judges from the start and clearly define the narrative. What are the key challenges your client faces? Did you experience any major unexpected challenges—and how did you deal with them? They are the hero of your story and your firm’s guide. You can transform these challenges into a great story that will enhance your project summary. Keep in mind, judges receive hundreds—sometimes thousands—of submissions, and if you don’t open strong in the first couple of sentences you might get tossed to the side and miss your opportunity for a blockbuster hit.

Similar to a well-crafted movie scene that conveys emotion, atmosphere, and storytelling, project photography plays a pivotal role in showcasing the design, craftsmanship, innovation, and impact. Project photography freezes a moment in time, closely resembling how a cinematic scene immerses viewers in the world of the story. Whether it’s capturing the grandeur of a skyscraper at sunset or the intimacy of a carefully designed interior space, project photography and movie cinema scenes share the common goal of conveying a narrative that resonates with viewers long after the image fades or the scene ends.

In conclusion, just like a well-crafted movie, an award-winning AEC project submission requires a combination of creativity, innovation, and storytelling prowess. By following the plotline of a blockbuster film—from setting up the story to delivering a satisfying resolution—you can create a submission that not only impresses the judges but leaves a lasting impact on the AEC industry. So, grab your metaphorical popcorn, and let the award-winning journey begin!

Dora Hughes is a Health, Safety, and Security Manager and has been with Knik Construction for fifteen years. She excels in ensuring safety, earning with her team a Safety Award for six consecutive accident-free years. Recognized with the ConocoPhillips Excellence in Safety Individual Award in 2020, Hughes’ contributions extend to assisting Knik with award-winning submissions for the 2023 Associated General Contractors, or AGC, of Alaska Parker, Smith & Feek Excellence in Construction and the 2024 AGC Build America Award for the Northern Region Western Coastal Storm Emergency Repairs Front Street & Nome Council Highway. Hughes also serves as a NAWIC board member and AGC of Alaska safety committee co-chair.

DIGITAL blueprint, Inc.

n 1994, Dave Dubois was an employee of Alaska Legal Copy.

“I brought engineering reproduction to their business, and the business grew so fast and strong; by the beginning of 1997, it was obvious that a business split had to occur in order to properly maintain all clients,” Dubois says. “Richard Blaylock, myself, and a person named Paul Krous found a home for the new business of DIGITAL blueprint, Inc.”

Dubois took the role of production manager and Krous became the general manager.

“Blaylock was ready to call it a career by the beginning of 2015, so after much discussion with my wife and a CPA, we decided to purchase my job,” Dubois says.

DIGITAL filled a void in Alaska that proved visionary.

“The main reason DIGITAL blueprint was created back in 1997 was to give a print alternative to the blueline industry,” says Dubois. “We were the first company to bring wide-format high-speed digital black and white output to Alaska. This helped create a specific, niche copy-and-print business that was needed for the architectural, engineering, and construction industry.”

Blueprints That Helped Build Alaska

“A full-size drawing in the hand of a contractor is a valuable construction tool,” Dubois says.

“There have been many people reviewing construction drawings on things like phones and tablets, but it requires a lot more time to pick the page, zoom into details, and to navigate within. I believe, as well as many contractors, that there is still no faster method for review than having a sheet of paper in your hands.”

The Hewlett Packard PageWide XL 8000 Printer is one of the fastest large-format printer ever, in monochrome and color.

He explains that blueprint technology is more than 150 years old, and blueprints were once the standard for printing architectural drawings. As with most business documents, technology has affected the practice.

“Even though we have modernized the way we print drawings to digital output, the concepts are still the same,” he says.

Expanding, Then Contracting

“By the year 2015—the year my wife and I purchased the facility from the original owners—technology changed the way business was working out,” he says. “Architects and engineers began to do a lot of their copies in-house, and this changed the dynamic of how we do business. As a result, the profits lowered dramatically, and we found ourselves struggling to maintain profitability in a 6,000 square-foot -facility. At that point we were looking for a new, downsized home and found it where we are now, at the corner of Fireweed and the New Seward Highway with 2,700 square feet and happy.”

Dubois notes that the uniqueness of his business sets it aside from other printers in town.

“We are not built to compete with normal print shops because of our specialty services.”

Administrator, Watterson Construction

Large-format printers like the Hewlett Packard PageWide XL 8000, the fastest large-format printer on the market, prints in both monochrome and color and helps customers meet

tight deadlines.

And the Epson SureColor P9570, designed for large-format printing, is a 44-inch wide-format inkjet printer that provides consistent color and fast print speeds for proofing, graphic design, and commercial and professional photography.

Roger Hickel Construction Project Manager Karen Deason says her company has used DIGITAL blueprint for twenty-three years and, in that time, it has been very professional, asked questions about the print job, and always brought the job in on time.

Dave Dubois, owner of DIGITAL blueprint, at its headquarters.

The Epson SureColor P9570 is designed for large-format printing, especially for fine art and photography.

Owner, DIGITAL blueprint, Inc.

At Watterson Construction, Administrator Nicole Coslet says Watterson has worked with DIGITAL for twenty-six years, and the company is very satisfied with DIGITAL blueprint’s work.

“If anything comes up, they fix it, and working with them has taught me a lot,” she says.

DIGITAL extends a 15 percent price discount to all AGC members because of its membership standing and the support it receives from AGC.

Hiring teens can provide them with valuable skills and opportunities for growth while helping to address the industry’s need for new talent.

Photo provided by iStock

Them Up

Photo provided by iStock

ard hats are on and safety vests gleam as a construction crew assembles for another day’s work. Among them are eager and energetic teenagers, ready to learn the ropes of the construction trade.

This is an ideal scenario for Matt Ketchum, a seasoned Southcentral Alaska contractor who believes in the power of youth and the potential they bring to the table. For him, hiring teens isn’t just about filling positions; it’s about investing in the future of the construction industry.

“I’ve always felt that our industry tends to look for experienced individuals,” says Ketchum, owner of K&H Civil Constructors in Wasilla. “But someone has to train [new workers], and it’s our responsibility to give young people a chance.”

Ketchum got his start in construction as a teenager while attending Dimond High School in Anchorage. His football coach got him a job working in home construction. This opportunity led him down a path he hadn’t initially considered, but the allure of the industry’s excitement and the promise of personal and financial rewards has kept him hooked ever since.

Nearly forty years later, he’s giving back by doing more to advocate for young workers.

“Personally, I like hiring younger individuals because they come with a clean slate,” he says. “You can teach them from the ground up, without having to unlearn any bad habits.”

Learning from Experience

“At a young age, working in the construction industry opened my eyes to so many new and exciting career opportunities,” Steer says. “I realized there were so many sectors of civil construction that could be applicable to my interests and skill sets.”

As Steer delved deeper into the world of construction, he found himself mentored by seasoned professionals who not only taught him the ins and outs of the trade but also imparted invaluable lessons about the lifestyle of working in construction and the importance of industry-wide safety.

Providing an opportunity for teens to work is a great way to introduce young people to the industry, says Matt Ketchum, owner of K&H Civil Constructors.

Photo provided by Matt Ketchum

Photo provided by Kolten Ketchum

Through his on-site experiences, Steer developed a variety of skills, from customer relations to time management, leadership, and the completion of diligent work. These skills not only made him an asset to K&H Civil Constructors but have given him a competitive edge in future job opportunities.

“My experience in the construction industry at a young age gave me an advantage over other qualified candidates during the job application process,” Steer says.

Initially, as a young worker, he faced a lack of experience, a hurdle that he overcame with the guidance of others.

“I was fortunate enough to be surrounded by great mentors,” he says.

Steer connected with Ketchum in middle school: Ketchum gave a presentation during one of Steer’s eighth-grade classes at Teeland Middle School in Wasilla.

He’s now a 21-year-old college student pursuing a degree in mining engineering at the Colorado School of Mines. He, too, is eager to pay it forward, offering advice to other young individuals considering a career in construction.

“Start with summer jobs,” Steer suggests. “It is crazy how much you learn by being around competent leaders, operators, surveyors, and human resource staff. From there you will start to realize what you like/dislike about different jobs and industries and can try something new in the future.”

Owner, K&H Civil Constructors

“I learned to respect every worker that comes to work to man a shovel or a rake all day long,” he says.

While Kolten acknowledged the sacrifices of missing out on typical teenage activities during summers spent working, he found solace in knowing that his efforts would benefit his future. He’s now a project engineer for Granite Construction.

Photo provided by Glenn Steer

“Companies are managing risk all the time,” he says. “While there are some risks with hiring someone under the age of 18, the benefits outweigh the risk.”

Ketchum has presented at many high schools in Matanuska-Susitna Borough School District about the construction industry and its opportunities. Kids like the presentations and are motivated by the financial rewards.

“Inevitably, a half dozen kids come up to me to ask where they can get a job,” he says.

AGC Alaska has more than 250 general contractor members and more than 300 associate members. If half of AGC members hired a young person just for the summer, Ketchum suggested, that would be more than 250 new young people in the industry.

“Many may choose the trades, business administration, project management, or another career path, but the impact year over year could be huge.”

Ketchum and his team made sure that their young recruits received the necessary training, both in terms of safety procedures and the intricacies of the job itself. For them, it was a hands-on approach, with learning happening in real-time on the construction site.

“Training primarily happens on the job,” says Ketchum. “We provide them with the basics and then let them learn as they go.”

Despite the restrictions involved in hiring minors under the Alaska Child Labor Law, which requires all minors 14-16 to have a work permit on file with the Alaska Department of Labor and Workforce Development, Ketchum believes the benefits far outweighed the challenges. This approach not only addresses the industry’s need for new talent, but it also provides young people with valuable skills and opportunities for growth.

While 17-year-olds do not need an approved permit, it must still be submitted to the Department of Labor. Ketchum emphasizes that his focus is to encourage AGC members to hire more 16 and 17-year-olds.

“I’ve seen firsthand the impact that exposure to the industry can have,” says Ketchum. “Giving young people a chance can change their lives and ours.”

Health

truck-by or dropped objects are a serious hazard at many worksites. In 2021, there were 227 workplace fatalities due to “struck by falling objects” in the United States, according to the US Bureau of Labor Statistics. The federal Occupational Safety and Health Administration, or OSHA, estimates that more than 50,000 “struck by a falling object” incidents occur each year on construction sites alone. These statistics only account for OSHA recordable incidents; it does not consider accidents from fallen objects that go unreported.

Dropped objects can also cause structural, environmental, and equipment-related damage on worksites. OSHA General industry standard number 1910.29 and Construction Fall Protection standard 1926.501(c) require that employers provide “protection from falling objects.”

Outsized Impact

Expanding a fall protection program to include tools and equipment is a good starting point. Companies and employees should implement an active fall protection program for tools and expand on the mission to encourage an inclusive culture of safety. Risk management by using the principle of the hierarchy of controls, a method of identifying and ranking protection measures from most to least effective, is the best approach to preventing injury. Engineering a hazard out altogether or utilizing alternative means of access to minimize fall risks is best practice. Here are a few tips:

The primary system to prevent tools and equipment from falling is tethering tools and equipment with connectors, connection points, and anchors. Many tools now have built-in connection points affixed by the manufacturer for tethering. Tools and other equipment can also be retrofitted to have connection points. These tools are then connected to an attachment point via a tethering device. Tools either can be connected to a worker through a tool belt, harness, or wristband, or anchored to a fixed structure.

These solutions not only apply to small hand tools but also can be used for tools and equipment that weigh up to 80 pounds, such as rivet busters, portable generators, et cetera.

Tools that weigh more than 5 pounds should never be tied to a person. If a heavy object gets loose, the weight and force of the falling object could dislocate a wrist or shoulder or even pull a worker over a ledge or from scaffolding.

Employees should be properly trained on how to use tethered tools. They must be taught how to attach a connection point to the tools, use the lanyards properly, and respect the weight rating of the lanyards. It is the responsibility of every safety manager, construction superintendent, supervisor, and worker to make sure they understand the dangers they face when working at height.

Learn to Return Training Systems

afety is by choice, not by chance, and Learn to Return Training Systems, or LTR, prepares occupational workers with the ability to handle emergency situations.

Through a series of immersive scenarios, LTR teaches Alaska’s workforce how to assess and react to danger and mitigate damage when necessary. Likewise, it helps develop a mindset aimed at prevention and confidence to work effectively in potentially hazardous environments.

Brian Horner, LTR director and founder, says survival training has evolved since his company started in 1986. For many years, arctic training and aviation survival were its two main courses, and LTR taught them to businesses, organizations, and government agencies on an

international level.

As family became a larger priority, Horner narrowed his company’s focus back on Alaska. He developed a series of medical training courses that went beyond Basic First Aid, followed by additional courses still taught at LTR today.

“The company changed when we decided to stay home more,” says Horner, “but it gave us a chance to provide training to our clients that was more relevant to their employees.”

The course is based on Wilderness Medical Society guidelines and consolidated American Red Cross First Aid programs. Attendees learn splinting, bandaging, small wound cleaning, and proper CPR techniques.

Founder and Director, Learn to Return Training Systems, Inc.

LTR’s Delayed Care, First Aid class is so popular that many companies and organizations will schedule it in conjunction with other occupational courses like Wilderness Bear Awareness and Defense, or Fall Protection.

“All the scenarios were realistic and held the attention of the class,” says Norby. “Every employee who has taken courses through Learn to Return always comments on how good the training is and how they would like more.”

Testimonials on the LTR website attest to the successful teaching method. Ben Benson of McLane Consulting, Inc. writes, “LTR, I just wanted to say that you guys have a very good program there. I thought the class moved smoothly and provided a huge amount of very useful information. Your staff was tremendous and I can tell everyone there was speaking from a lot of experience, not just out of a book. I’m sure, like many that enter your class, I didn’t think I needed further outdoor training, and I wasn’t going to learn anything new. But I was very impressed with the amount of new information I took from the class.”

Safety Representative, Colaska, Inc.

“There are a lot of places that offer recreational gear locally,” says Horner. “But we are the only place in Anchorage that offers industrial gear like this.”

In 2019, Learn to Return received the Micro-Business of the Year Award at the US Small Business Administration Awards Ceremony. US Senator Dan Sullivan thanked LTR for creating a business model that helps Alaskans learn critical skills to survive in the beautiful—but sometimes harsh—Alaska climate.

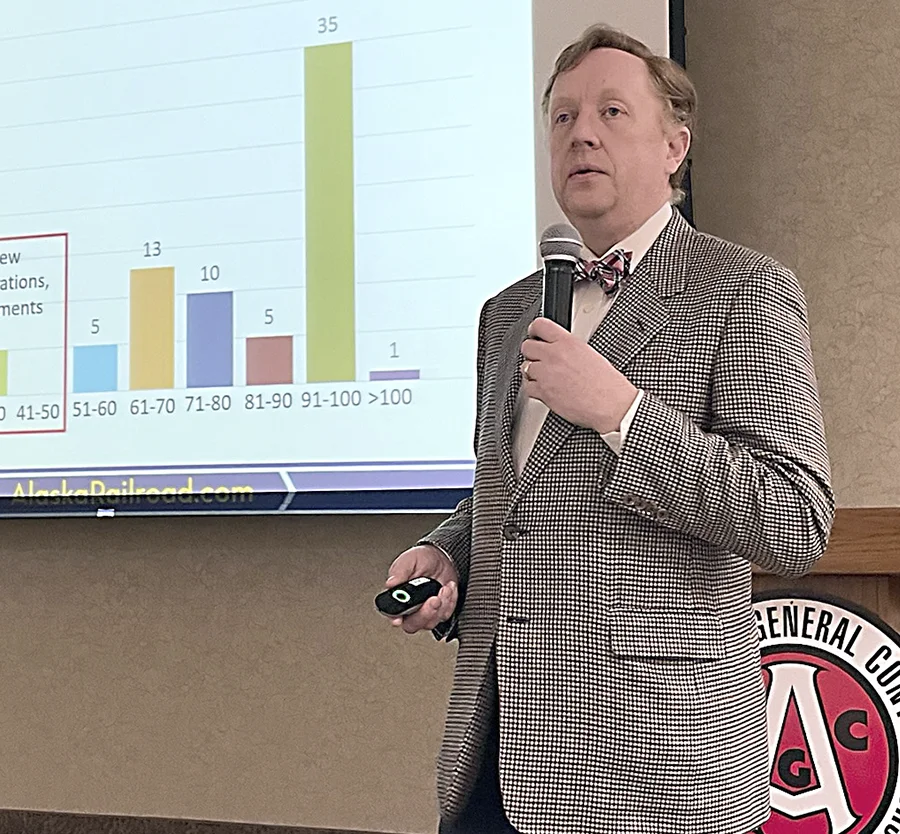

icking off the construction season, the Associated General Contractors, or AGC, of Alaska Spring Agency Day and AGC full board and membership meeting, held April 11 at Wedgewood Resort in Fairbanks, offered an opportunity for members to learn about upcoming state and federal projects, including those through the Department of Transportation and Public Facilities, the US Army Corps of Engineers-Alaska District, the Alaska Railroad, and the Alaska Native Tribal Health Consortium. Sandwiched between updates and the AGC full board and membership meeting is the Spring Kick-Off party, an opportunity for members to reconnect after the winter and celebrate the beginning of the construction season.

- Acrisure

- Brice, Inc.

- Coldfoot Environmental Services, Inc.

- Davis Constructors & Engineers, Inc.

- Denali Industrial Supply, Inc.

- Drake Construction, Inc.

- Emulsion Products

- Equipment Source, Inc.

- Exclusive Paving/University Redi Mix

- GHEMM Company, LLC

- Granite Construction Company

- Great Northwest, Inc.

- Hale & Associates, Inc.

- Hamilton Construction Alaska

- HC Contractors, LLC

- Holland & Hart, LLP

- North Star Equipment Services

- Parker, Smith & Feek, LLC

- PFK Enterprises, Inc.

- Quality Asphalt Paving (QAP)